A kind of polymeric dispersant and environment-friendly surface sizing agent prepared by adopting the dispersant

A technology of polymerizing dispersant and surface sizing agent, applied in the direction of adding water repellent, can solve problems such as residue and multi-VOC, and achieve the effect of good water resistance, low Cobb value and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

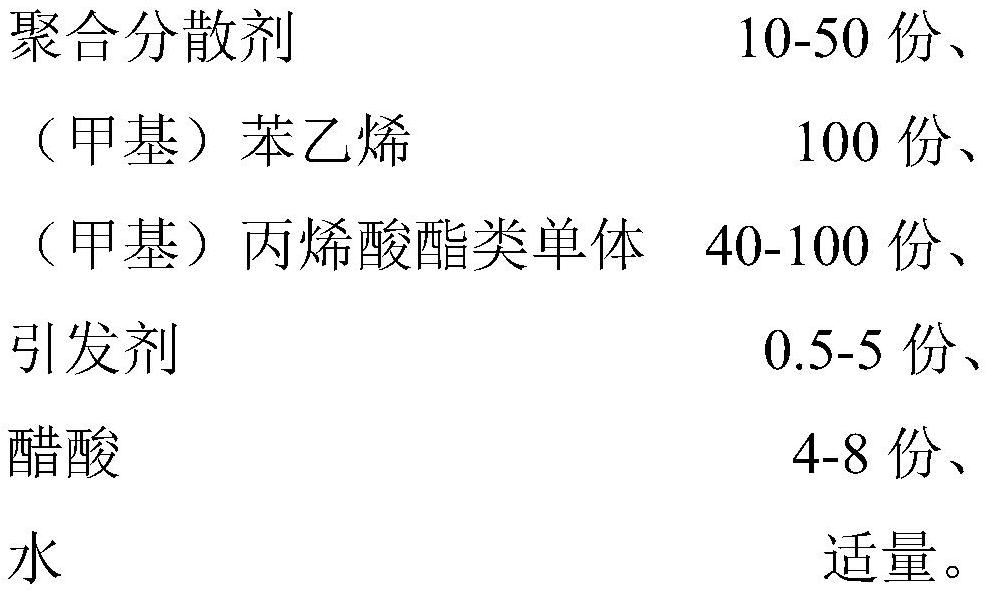

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of polymeric dispersant:

[0032] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, add 100 grams of maleic anhydride and 600 grams of polyvinyl alcohol, heat and melt, and react at 80° C. for 3 hours. The temperature was lowered to 40° C., 120 g of chlorosulfonic acid was added, and the reaction was continued for 1 hr.

[0033] 2. Preparation of environmentally friendly surface sizing agent:

[0034] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, add 10g of polymeric dispersant, 500g of deionized water, 4g of acetic acid and then heat up to 80°C, and add 1g of ammonium persulfate. After 10 min of reaction, 180 g of mixed monomers (100 g of styrene, 80 g of ethyl acrylate) were slowly added dropwise, and the dropwise addition was completed in 1.5 hr. 0.5 g of ammonium persulfate was added to continue the reaction for 1 hr. After cooling, it was filtered throu...

Embodiment 2

[0036] 1. Preparation of polymeric dispersant:

[0037] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, add 100 grams of maleic anhydride and 650 grams of polyvinyl alcohol, heat to dissolve, and react at 90° C. for 3 hours. The temperature was lowered to 50° C., 125 g of chlorosulfonic acid was added, and the reaction was continued for 1.5 hr.

[0038] 2. Preparation of environmentally friendly surface sizing agent:

[0039] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer, and a thermometer, add 20 grams of polymeric dispersant, 600 grams of deionized water, 4 grams of acetic acid, and then raise the temperature to 90°C, and add 1 grams of potassium persulfate. After 10 min of reaction, 200 g of mixed monomers (100 g of styrene, 100 g of n-butyl acrylate) were slowly added dropwise, and the dropwise addition was completed in 2.0 hr. 0.5 g of potassium persulfate was added to continue the reaction f...

Embodiment 3

[0041] 1. Preparation of polymeric dispersant:

[0042] In a 1000ml four-necked flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 100 grams of maleic anhydride and 700 grams of polyvinyl alcohol, heat to dissolve, and react at 95°C for 3 hours. The temperature was lowered to 50° C., 130 g of chlorosulfonic acid was added, and the reaction was continued for 2.5 hr.

[0043] 2. Preparation of environmentally friendly surface sizing agent:

[0044] In a 1000ml four-necked flask with a condenser, a dripping device, a stirrer and a thermometer, add 35g of polymeric dispersant, 530g of deionized water, 4g of acetic acid and then heat up to 90°C, add 3g of dibenzoyl peroxide . After 15 min of reaction, 160 g of mixed monomers (100 g of styrene, 60 g of isooctyl acrylate) were slowly added dropwise, and the dropwise addition was completed in 2.0 hr. 1.0 g of potassium persulfate was added to continue the reaction for 1 hr. After cooling, it was f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com