Efficient surface sizing agent for paper and preparation method and application of efficient surface sizing agent

A surface sizing agent, high-efficiency technology, applied in the direction of water-repellent addition, etc., can solve the problems of powder falling off, etc., and achieve the effect of improving smoothness, anti-moisture ability, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of described surface sizing agent comprises the following steps:

[0028] (1) Pre-polymerization stage: Add 4-8wt% glacial acetic acid and 0.05-0.4wt% initiator into the reactor, stir and heat up; the temperature rises to 90-120°C, and start to drop 15-25wt% hard monomer, 5 ~15wt% cationic monomer, 0.5~4wt% unsaturated carboxylic acid, 6~11wt% glacial acetic acid, 0.2~0.6wt% initiator, the dropping time is 30~90min; Finished, and began to add 40 to 60 parts of deionized water dropwise, and the dropping time was 60 minutes; after the dropping, the temperature was lowered to 85°C, and kept for 30 to 45 minutes;

[0029] The hydrophilic-lipophilic equilibrium value of the prepolymer is 3-10, the critical micelle concentration is 0.2-0.7 g / L, the molecular weight is 10,000-100,000, and the content of dimethylamine or trimethylamine group is It is 0.4-0.6 mmol / g.

[0030] (2) Polymerization stage: Add 0.03-0.07wt% initiator and 0.01-0.03wt% defoamer ...

Embodiment 1

[0035] Pre-polymerization stage: Add 6wt% glacial acetic acid and 0.15wt% AIBN azobisisobutyronitrile into the reactor, stir and raise the temperature; when the temperature rises to 120°C, start to drop 20wt% St, 10wt% DMAPMA, 2wt% AA and 10wt% % glacial acetic acid, 0.4wt% AIBN, the dropping time is 60min; after the dropping, keep warm for 60min, after the warming is over, cool down to 100°C, and start adding 50 parts of deionized water, the dropping time is 60min; to 85°C and keep warm for 50min.

[0036] Polymerization stage: add 0.05wt% ferrous sulfate and 0.02wt% defoamer to the above prepolymer in the autoclave; continue to drop 40wt% St, 28wt% t-BA and 25wt% deionized water after stirring well , 3wt% concentration of 30% H 2 o 2 , the dropping time is 120min, and the dropping temperature is 80°C; at the end of dropping, keep warm at 80°C for 60min, add sodium hyposulfite formaldehyde and lower the temperature at the end of the warming, finally add 0.08wt% defoamer, an...

Embodiment 2~11

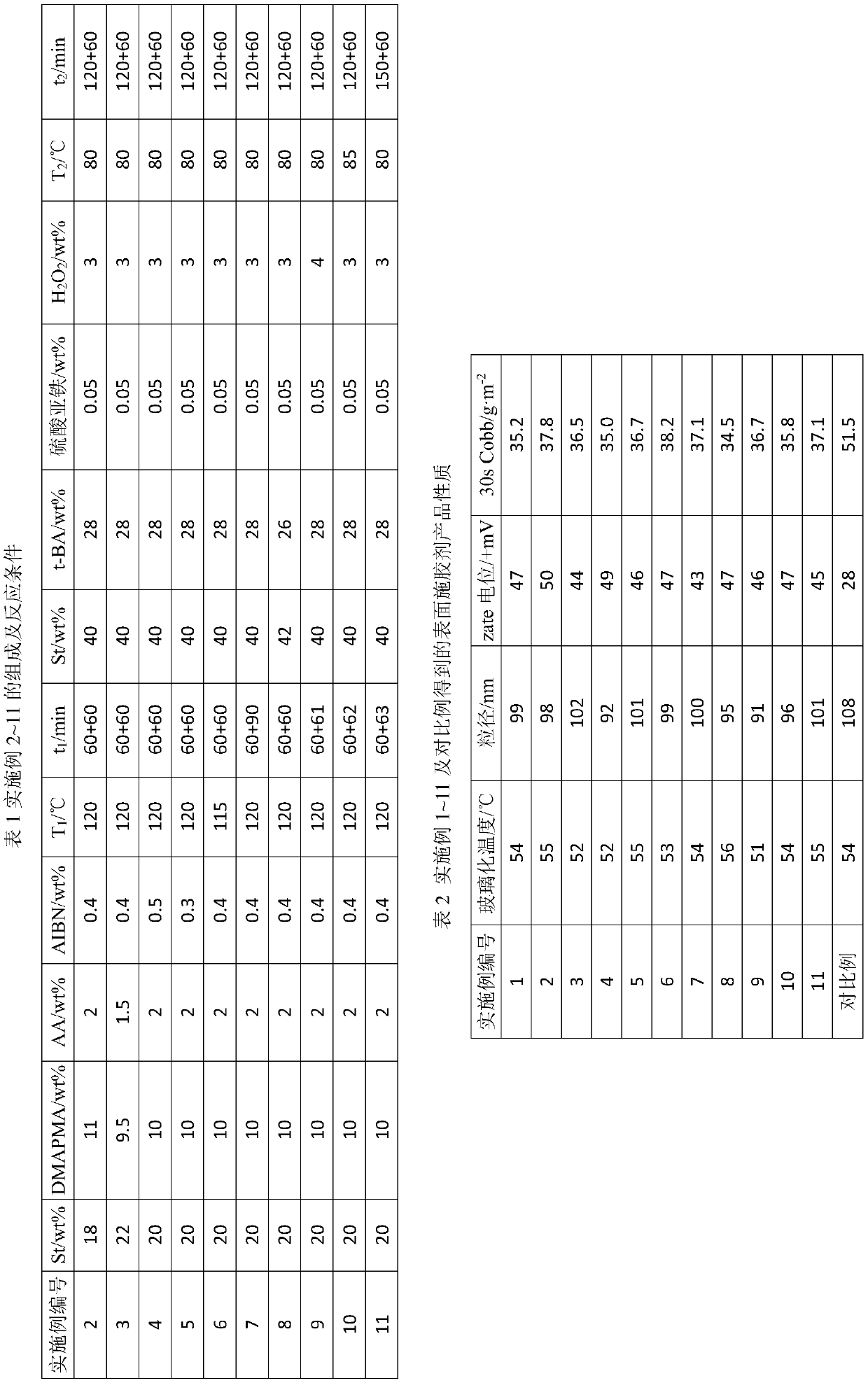

[0039] The reaction process of Examples 2 to 11 is the same as that of Example 1. Table 1 shows the composition, changes in reaction conditions and properties of the corresponding emulsion.

[0040] The corresponding English abbreviations in Table 1 are as follows: St-styrene; DMAPMA-dimethylaminopropyl methacrylamide; AA-acrylic acid; AIBN-azobisisobutyronitrile; T 1 - Reaction temperature in the prepolymerization stage; t 1 - monomer addition time + holding time in the pre-polymerization stage; t-BA-tert-butyl acrylate; T 2 - Reaction temperature in the polymerization stage; t 1 -Monomer & initiator dropping time + holding time in polymerization stage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com