Fixation crosslinking agent, and producing method

A color-fixing cross-linking agent and production method technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as inability to achieve color-fixing effect, less reactive groups, poor reaction ability, etc., and achieve good color-fixing effect , strong reactivity, and the effect of improving reaction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Neutralization reaction: add trimethylamine 125Kg in stainless steel kettle, neutralize with hydrochloric acid (37%) 28-30Kg, temperature is kept on 20-40 ℃, and the pH value of adjustment product is till 5.

[0027] (2) Quaternization reaction: raise the temperature of the reaction kettle to 45-50°C, slowly add 76Kg of epichlorohydrin dropwise, complete the dropwise addition within 1.5 hours, and keep the reaction for 4-4.5 hours.

[0028] (3) Polymerization reaction: under the condition of stirring at 20-40°C, slowly drop the mixture of 30Kg of cyanuric chloride and 24Kg of acetone into the reaction kettle, and adjust the pH with 8-12Kg of sodium carbonate (30%) at any time The value is 6.5 until it remains the same after 20 minutes. Raise the temperature to 65-70°C, gradually add a solution of 36Kg of hexamethylenediamine and 300Kg of water under stirring, and keep the reaction temperature at 65-70°C. After the dropwise addition, keep the temperature for 2.5 hou...

Embodiment 2

[0030] Raw material ratio: trimethylamine 140Kg, hydrochloric acid (37%) 43Kg, epichlorohydrin 80Kg, sodium carbonate (30%) 12Kg, acetone 28Kg, cyanuric chloride 40Kg, hexamethylenediamine 45Kg, water 400Kg, the production process is the same Example 1.

[0031] The using method of color-fixing cross-linking agent of the present invention

[0032] 1. After dyeing, fix the color and use:

[0033] Mix this product with water 10g / l, dip twice, roll twice, and dry.

[0034] 2. Application as a cross-linking agent for pigment printing: add 0.5-0.8% of this product to the pigment printing paste, and then bake after printing. It can significantly improve the rubbing fastness, especially the wet rubbing fastness above half grade. Similarly, the application of DUR and TinofixExo as crosslinking agent for pigment printing has no obvious effect.

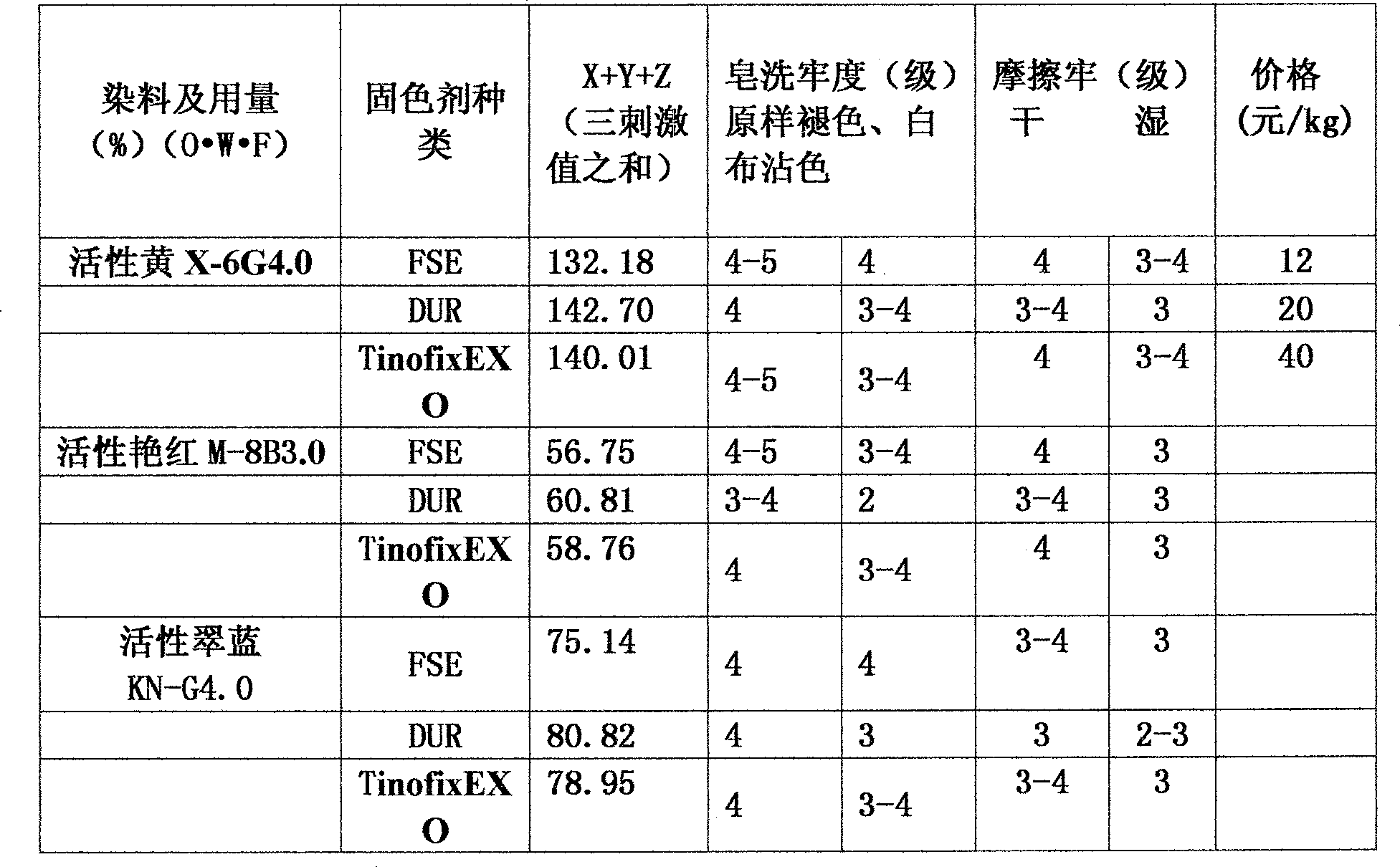

[0035] This product (code-named FSE) is compared with the formaldehyde-free color-fixing agent DUR of Shanghai Auxiliary Factory and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com