A kind of starch emulsifier, preparation method and anionic akd surface sizing agent prepared by using the emulsifier

A surface sizing agent and emulsifier technology, applied in the direction of water repellent addition, papermaking, coating, etc., can solve problems such as paper defects, increased cost of additive dosage, and affect paper quality, so as to improve printing suitability and increase The effect of surface strength and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

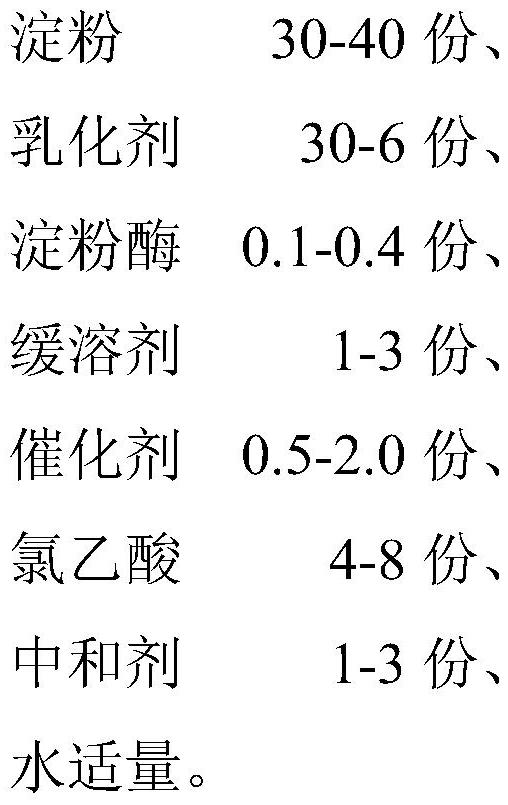

Method used

Image

Examples

Embodiment 1

[0022] (1) preparation of starch emulsifier:

[0023] In a four-necked flask equipped with a condenser, agitation and a thermometer, add 185g deionized water, 4g sorbitan monooleate (Span 80), 1g α-amylase and 100g cornstarch, heat up to 60°C, keep warm 1h, add slow solvent anhydrous sodium sulfate 5g under stirring, add sodium hydroxide with a weight concentration of 32% until the pH of the solution is 11.0, add 10g of water to dissolve 7g of chloroacetic acid in another beaker, and then add it to the starch milk, the reaction 4h, the pH of the system was adjusted to 4.0 with hydrochloric acid. Cool down to below 30°C, filter and discharge.

[0024] (2) Preparation of anionic AKD surface sizing agent:

[0025] In a four-necked flask equipped with a condenser, agitation and a thermometer, add 50g of starch emulsifier and 100g of water, heat up to 75°C, add 100g of molten AKD original powder, stir at high speed for 20 minutes, pour into a high-pressure homogenizer at 40MPa Q...

Embodiment 2

[0027] (1) preparation of starch emulsifier:

[0028] In a four-necked flask equipped with a condenser, stirring and a thermometer, add 150g deionized water, 10g polyethylene oxide (20), 1g β-amylase and 100g corn starch, heat up to 55°C, keep the temperature for 2h, and add a slow solvent under stirring 8g of sodium chloride, add sodium hydroxide with a weight concentration of 32% until the pH of the solution is 12.0, add 10g of water to dissolve 9g of chloroacetic acid in another beaker, then add it to the starch milk, react for 6h, and adjust the pH of the system with phosphoric acid to 3.0. Cool down to below 30°C, filter and discharge.

[0029] (2) Preparation of anionic AKD surface sizing agent:

[0030] In a four-necked flask equipped with a condenser, agitator, and a thermometer, add 40g of starch emulsifier and 100g of water, raise the temperature to 80°C, add 100g of molten AKD raw powder, stir at high speed for 10 minutes, and pour it into a high-pressure homogeni...

Embodiment 3

[0032] (1) preparation of starch emulsifier:

[0033] In a four-necked flask equipped with a condenser tube, agitation, and a thermometer, add 170 g of deionized water, 8 g of sorbitan monolaurate (Span 20), 1 g of γ-amylase-amylase and 100 g of wheat starch, and heat up to 45 ℃, keep the temperature for 2h, add 5g of slow solvent anhydrous sodium sulfate under stirring, add sodium hydroxide with a weight concentration of 32% until the pH of the solution is 12.5, add 10g of water to another beaker to dissolve 10g of chloroacetic acid, and then add it to the starch milk During the reaction for 5h, the pH of the system was adjusted to 4.0 with acetic acid. Cool down to below 30°C, filter and discharge.

[0034] (2) Preparation of anionic AKD surface sizing agent:

[0035] In a four-necked flask equipped with a condenser, agitation and a thermometer, add 50g of starch emulsifier and 100g of water, heat up to 75°C, add 100g of molten AKD original powder, stir at high speed for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com