A kind of preparation method of surface sizing agent for corrugated paper and its product and application

A surface sizing agent and corrugated paper technology, which is applied in paper, papermaking, water repellent addition, etc., can solve the problems of high cost, large amount of sizing agent, failure to significantly improve the ring compressive strength of corrugated paper, etc., and achieve an increase in ring pressure The effect of strength, accelerated curing speed, and reduced Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In a first aspect, a method for preparing a surface sizing agent for corrugated paper is provided, comprising the following steps:

[0037] Mix the surface sizing agent base material for corrugated paper and cationic additives evenly to obtain the surface sizing agent for corrugated paper; wherein, the usage amount of the surface sizing agent base material for corrugated paper is 100 parts by weight, and the cationic The usage amount of additive is 5~50 parts by weight;

[0038] Wherein, the preparation method of the corrugated paper surface sizing agent base material comprises the following steps:

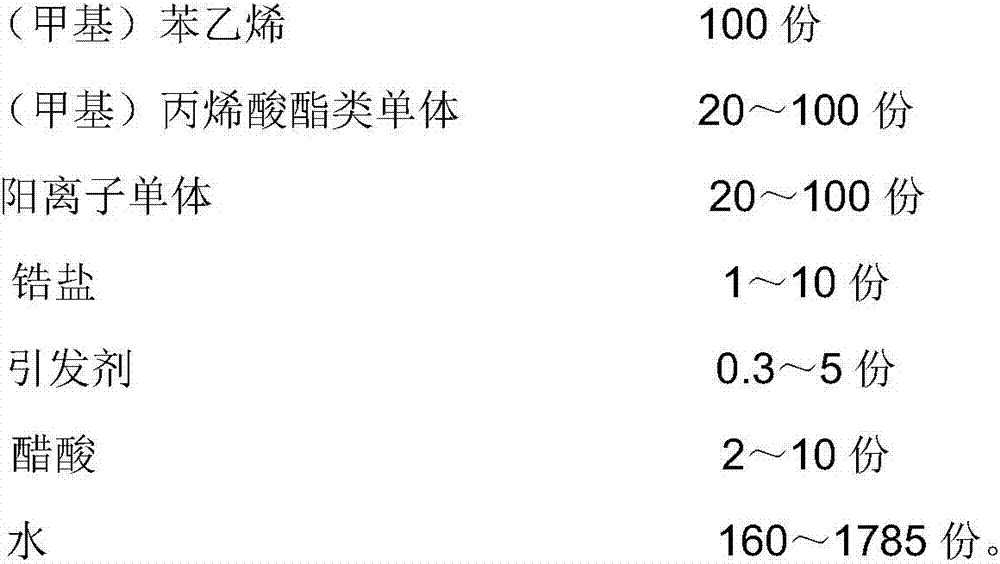

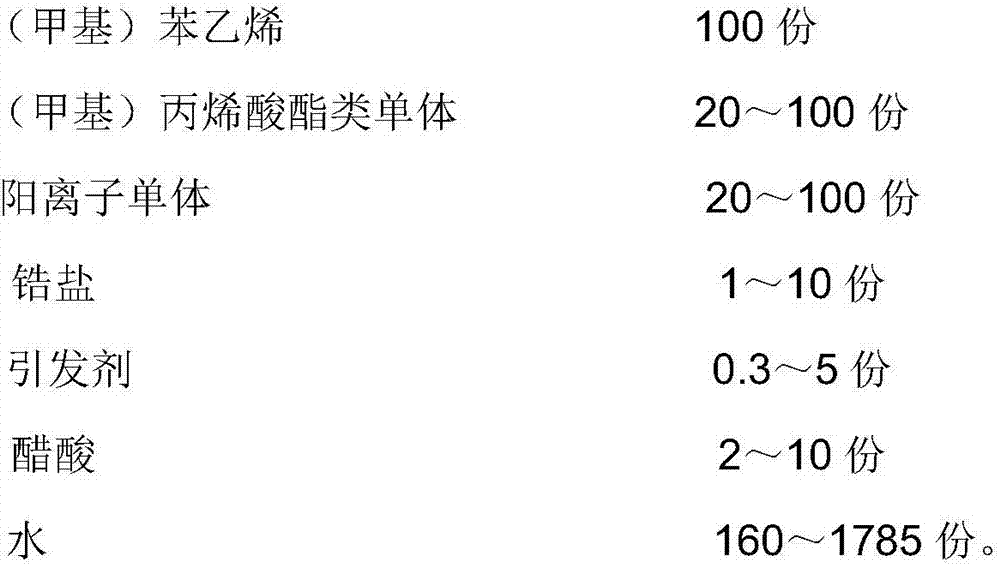

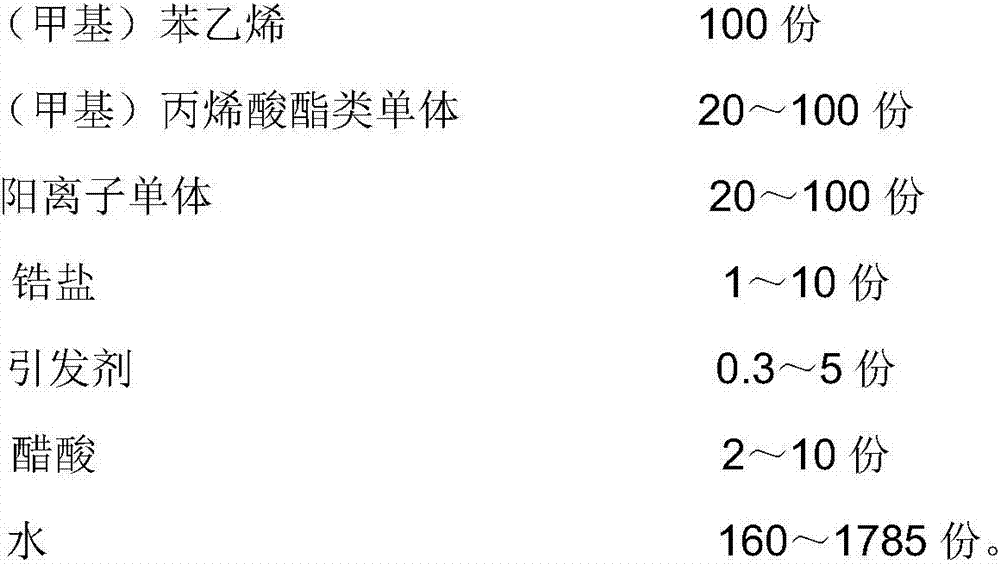

[0039] Add cationic monomers, zirconium salts, (meth)acrylate monomers, (methyl)styrene, initiators, acetic acid and water into a reaction vessel to carry out free radical polymerization to generate the surface-applied corrugated paper. Adhesive base;

[0040] Wherein, the preparation method of described cationic additive comprises the steps:

Embodiment 1

[0056] (1) Preparation of surface sizing agent base material for corrugated paper:

[0057] A) Add 100g of styrene, 20g of n-butyl acrylate, 20g of N,N-dimethylaminoethyl acrylate, and 0.3g of dibenzoyl peroxide into the container and mix evenly to obtain a mixed monomer, which is set aside ;

[0058] B) Warm up 161.47g of deionized water to 80°C for later use;

[0059] C) In a four-neck flask equipped with a condenser, dropping device, stirrer, and thermometer, first add 10% of the mixed monomer obtained in step A), raise the temperature to 80°C, and add step A dropwise after stirring for 10 minutes ) for the remaining mixed monomer obtained, dropwise for 5 hours, continue to insulate at 80°C for 1 hour after the dropwise addition, then add 10g of acetic acid, stir and react at 80°C for 1 hour, then add the hot water in step B), continue Stir the reaction for 1 hour, cool to 25° C., add 1 g of zirconium carbonate, stir evenly, and the pH=2.10. Filter through a 100-mesh fil...

Embodiment 2

[0066] (1) Preparation of surface sizing agent base material for corrugated paper:

[0067] A) Add 100g of methylstyrene, 100g of isooctyl acrylate, 100g of methacrylamidopropyl dimethylamine, and 5g of tert-butyl peroxybenzoate into the container and mix evenly to obtain a mixed monomer, which is set aside ;

[0068] B) 1783g of deionized water is heated up to 100°C and set aside;

[0069] C) In a four-necked flask equipped with a condenser, dropping device, stirrer, and thermometer, first add 20% of the mixed monomers obtained in step A), raise the temperature to 140°C, stir and react for 10 minutes, then add step A dropwise ) for the remaining mixed monomer obtained, dropwise for 1 hour, continue to insulate at 140°C for 0.5 hour after the dropwise addition, then add 2g of acetic acid, stir and react at 140°C for 20 minutes, then add the hot water in step B), and cool down Stir and react at 95°C for half an hour, then cool to 25°C, add 10g of zirconium carbonate, stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com