Cationic tert-carbonic acid styrene-acrylic emulsion and preparation method thereof

A technology of carbonated styrene-acrylic milk and styrene-acrylic emulsion, which is applied in the direction of water-repellent addition, coating, paper coating, etc., and can solve problems such as troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

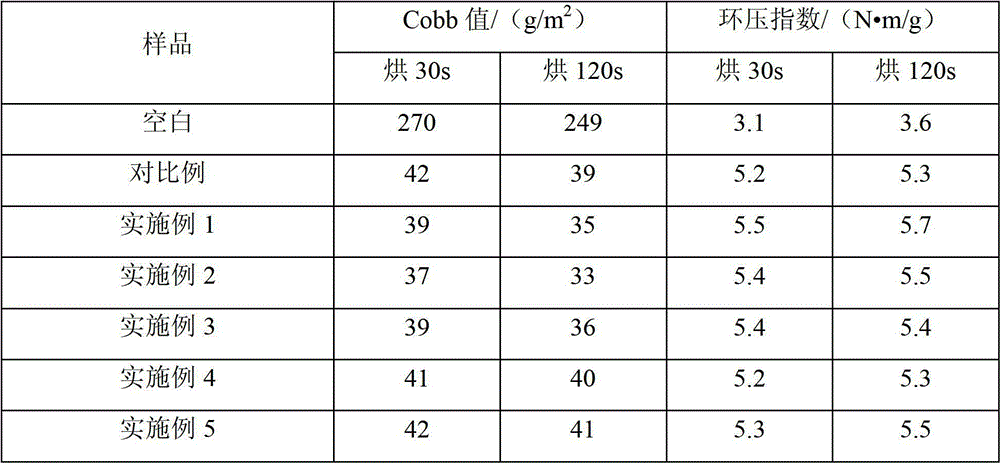

Examples

Embodiment 1

[0024] Synthesis of cationic tertiary carbonate styrene-acrylic emulsion:

[0025] a) 30g of n-butyl acrylate, 65g of styrene, 5g of acrylic acid and 10g of VeoVa9 are mixed to make a mixed monomer for subsequent use;

[0026] b) Dissolve 0.1g of ethylene glycol fatty acid ester, 0.06g of polyoxyethylene (20) sorbitan monooleate (Tween 80), and 0.2g of potassium persulfate in 10g of deionized water, and set aside;

[0027] c) Dissolve 0.9g (2,3) epoxypropyltrimethylammonium chloride (ETA) in 20 deionized water and set aside;

[0028] d) Add 0.5g ethylene glycol fatty acid ester, 0.2g polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.3g potassium persulfate and 40g Dissolve deionized water into an aqueous solution, stir for 30 minutes, and set aside;

[0029] e) Add 0.06g of ethylene glycol fatty acid ester, 0.07g of polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.2g of potassium persulfate and 23.6 In the aqueous solution of g deionized water, react at 70 ...

Embodiment 2

[0032] Synthesis of cationic tertiary carbonate styrene-acrylic emulsion:

[0033] a) Mix 20g of n-butyl acrylate, 75g of styrene, 5g of acrylic acid and 5g of VeoVa9 to make a mixed monomer for later use.

[0034] b) Dissolve 0.12g of ethylene glycol fatty acid ester, 0.16g of polyethylene oxide (20) sorbitan monooleate (Tween 80), and 0.25g of potassium persulfate in 10g of deionized water. spare.

[0035] c) Dissolve 0.75 g (2,3) epoxypropyltrimethylammonium chloride (ETA) in 20 deionized water. spare.

[0036] d) Add 0.6g ethylene glycol fatty acid ester, 0.3g polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.3g potassium persulfate and 40g Dissolve in deionized water to form an aqueous solution and stir for 30 minutes. spare.

[0037] e) Add 0.16g of ethylene glycol fatty acid ester, 0.17g of polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.2g of potassium persulfate and 23.6 In the aqueous solution of g deionized water, react at 70 for 40 minutes, ...

Embodiment 3

[0040] Synthesis of cationic tertiary carbonate styrene-acrylic emulsion:

[0041] a) Mix 20g of n-butyl acrylate, 75g of styrene, 10g of acrylic acid and 5g of VeoVa9 to make a mixed monomer for later use.

[0042] b) Dissolve 0.15 g of ethylene glycol fatty acid ester, 0.1 g of polyethylene oxide (20) sorbitan monooleate (Tween 80), and 0.25 g of potassium persulfate in 10 g of deionized water. spare.

[0043] c) Dissolve 0.55 g (2,3) epoxypropyltrimethylammonium chloride (ETA) in 20 deionized water. spare.

[0044]d) Add 0.6g ethylene glycol fatty acid ester, 0.3g polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.3g potassium persulfate and 40g Dissolve in deionized water to form an aqueous solution and stir for 30 minutes. spare.

[0045] e) Add 0.16g of ethylene glycol fatty acid ester, 0.17g of polyethylene oxide (20) sorbitan monooleate (Tween 80), 0.2g of potassium persulfate and 23.6 In the aqueous solution of g deionized water, react at 70 for 40 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com