Water-resistant surface sizing agent as well as preparation method and application thereof

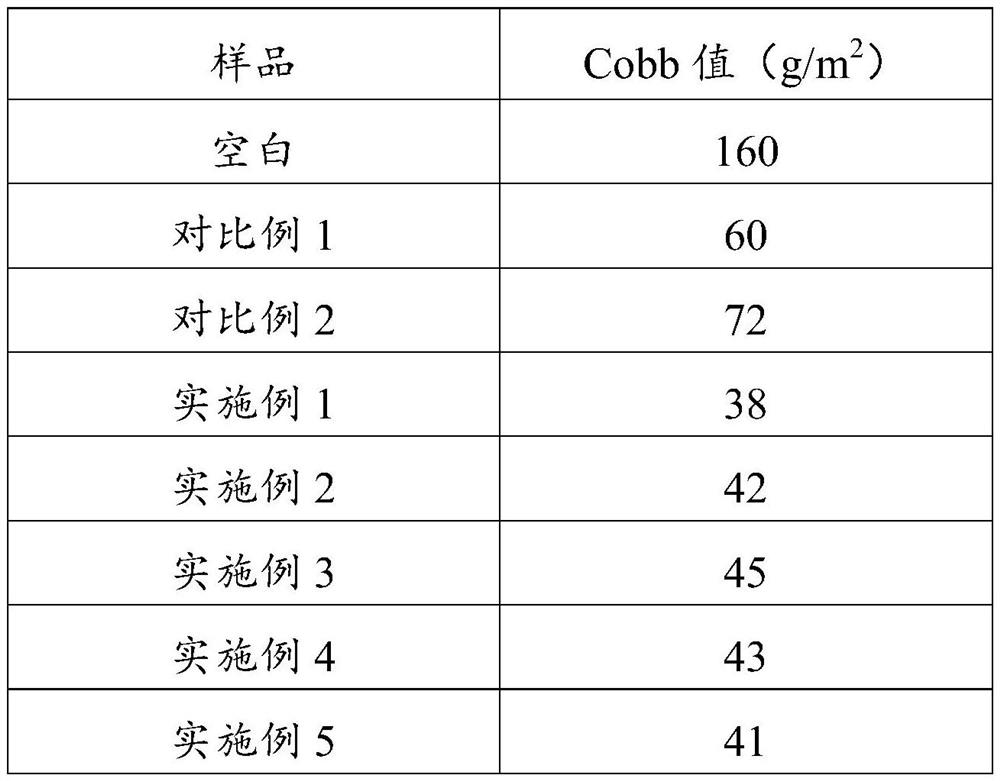

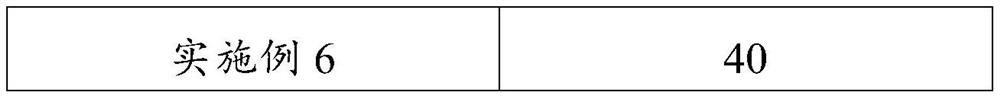

A surface sizing agent and water-resistant technology, which is applied in the direction of adding water repellent to achieve the effect of improving water resistance, reducing Cobb value and strengthening bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of water resistant surface sizing agent:

[0028] 20 grams of oxidation of starch, 190 g of deionized water were mixed together, and the four flask was added to 40 ° C, and 6 g of liquid base was added, and the pH to 11 or more, the temperature was tapered to 70 ° C, and the reaction was 30 min, and 16 g of formaldehyde solution, After 4 HR, 150 g of deionized water was added; heated to 90 ° C, 2.5 g of potassium sulfate, and dripped the mixed monomer (100 g styrene, 60 g of acrylate) 1.5HR. 0.7 g of ammonium sulfate, 140 g of deionized aqueous solution was added dropwise, and 2HR was added dropwise. After the dropwise addition was completed, the reaction was continued for 1HR. After cooling, the surface sizing agent was filtered with a 325 mesh filter, pH = 3.4, solid content = 27.8%.

Embodiment 2

[0030] Preparation of water resistant surface sizing agent:

[0031] 30 grams of oxidation of starch, 200 grams of deionized water were mixed together, and the four flask was raised to 45 ° C, and 9 g of liquid base was added, and the pH to 11 or more, the temperature was increased to 75 ° C, and 16 g of propylene oxide was added. After the reaction 4HR, 150 g of deionized water was added; the temperature was tapered to 90 ° C, and 0.4 g of ammonium sulfate was added, and the mixed monomer (100 g of styrene, 70 g of acrylate) was added dropwise, and completed after 10 minutes. 0.8 g of ammonium sulfate, 150 g of deionized aqueous solution was added dropwise, and 2HR was added. After the dropwise addition was completed, the reaction was continued for 1HR. After cooling, the surface sizing agent was filtered with a 325 mesh filter, pH = 3.7, solid content = 28.2%.

Embodiment 3

[0033] Preparation of water resistant surface sizing agent:

[0034] 40 grams of oxy starch, 200 grams of deionized water were mixed together, and the four flask was added to 45 ° C, and 10 g of liquid base was added, adjusted pH to 11 or more, heated to 65 ° C, after 30min, 12 g of epoxy chloride Propylene, reaction 4HR, 160 g of deionized water; heating to 90 ° C, add 2.5 g of tert-butyl hydrogen peroxide, reflecting a mixed monomer (100 g styrene, 75 g of butyl butyl butyl butyl butyl butyl butyl butyl butter) 1.5 hr drop Finish. The mixture was added dropwise addition of 3.0 g of tert-butyl hydrogen peroxide, 150 g of deionized aqueous solution, and 2HR was added. After the dropwise addition was completed, the reaction was continued for 1HR. After cooling, the surface sizing agent was filtered through the 325 mesh filter, pH = 3.6, solid content = 27.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com