A kind of modified sizing starch, surface sizing liquid and its preparation method and application

A technology for surface sizing and sizing starch, applied in textiles and papermaking, recycling technology, papermaking, etc., can solve the problems of complex preparation process and high preparation cost of surface sizing solution, achieve good system stability and improve water resistance. performance, the effect of reducing the Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

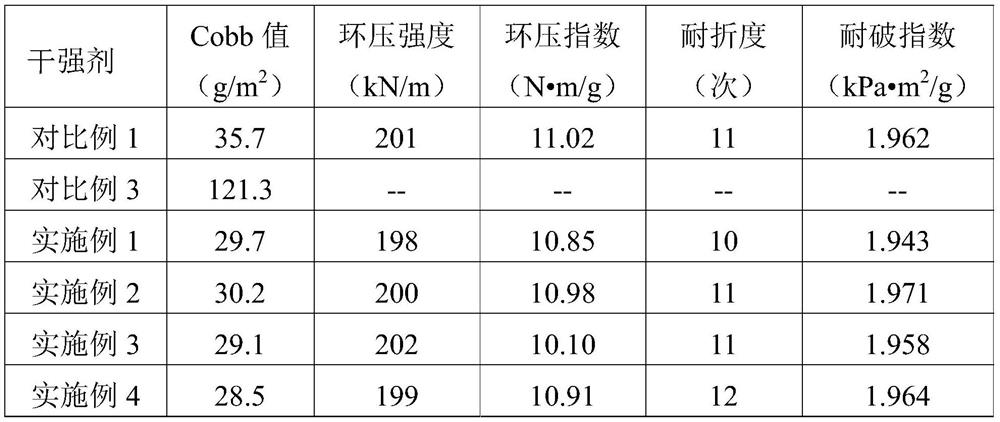

Examples

Embodiment 1

[0065] 1. Preparation of modified sizing starch

[0066] (1) under the condition that pH is 4.8~5.2, temperature is 50 ℃, and the condition of stirring, drop into glass reaction kettle 280g solid content is 27% pre-hydrolyzate, 6.3g mass percent are 32% sodium hydroxide aqueous solution , 25g tapioca starch, mixed evenly to prepare material A;

[0067] (2) under the condition that temperature is 50 ℃, add 0.08g ferrous sulfide and 2.5g mass percent of hydrogen peroxide aqueous solution that is 28% in material A, mix, continue to heat up, keep warm under the condition of 75-78 ℃ Stir for 2h to prepare material B;

[0068] (3) Mixing the material B, 0.8 g of sodium nitrite and 21.8 g of deionized water, cooling to room temperature, and discharging to obtain a modified surface sizing starch with a solid content of 30%.

[0069] 2. Preparation of surface sizing solution

[0070] Mixing the obtained modified sizing starch with an aqueous solution of corn starch with a solid cont...

Embodiment 2

[0072] 1. Preparation of modified sizing starch

[0073] (1) under the condition that pH is 4.8~5.2, temperature is 52 ℃, and stirring condition, drop 210g of pre-hydrolyzed solution that solid content is 24%, 4.8g mass percent of sodium hydroxide aqueous solution that is 40% in glass reactor , 19g cornstarch, mix evenly to prepare material A;

[0074] (2) under the condition that temperature is 50 ℃, add 0.03g chromium monoxide and 2g mass percent of hydrogen peroxide aqueous solution that is 28% in material A, mix, continue to heat up, keep stirring under the condition of 78-81 ℃ 1.5h, material B was obtained;

[0075] (3) Mixing the material B, 0.4 g of potassium iodide and 98 g of deionized water, cooling to room temperature, and discharging to obtain a modified surface sizing starch with a solid content of 31%.

[0076] 2. Preparation of surface sizing solution

[0077] Mixing the obtained modified sizing starch with an aqueous solution of corn starch with a solid cont...

Embodiment 3

[0079] 1. Preparation of modified sizing starch

[0080] (1) under the condition that pH is 4.8~5.2, temperature is 50 ℃, and stirring condition, put 160g of pre-hydrolyzed solution with solid content of 16%, 3.2g of sodium carbonate, 16g of wheat starch into glass reaction kettle, mix well, Material A is obtained;

[0081] (2) under the condition that temperature is 50 ℃, add 0.02g vanadium dichloride and 1.8g mass percent of hydrogen peroxide aqueous solution that is 28% in material A, mix, continue to heat up, under the condition of 75-78 ℃ Keep stirring for 1h to obtain material B;

[0082] (3) Mixing the material B, 0.3 g of tert-butanol and 109 g of deionized water, cooling to room temperature, and discharging to obtain a modified surface sizing starch with a solid content of 15%.

[0083] 2. Preparation of surface sizing solution

[0084] Mixing the obtained modified sizing starch with an aqueous solution of corn starch with a solid content of 10% according to a dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cobb value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com