Modified sizing starch, surface sizing liquid, preparation method of modified sizing starch, and application of surface sizing liquid

A technology of sizing starch and surface sizing, which is applied in textiles and papermaking, adding water repellents, without pigment coating, etc., can solve the problems of complicated preparation process, non-degradable raw materials, and high preparation cost, and improve water resistance. , The effect of reducing Cobb value and saving workshop cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

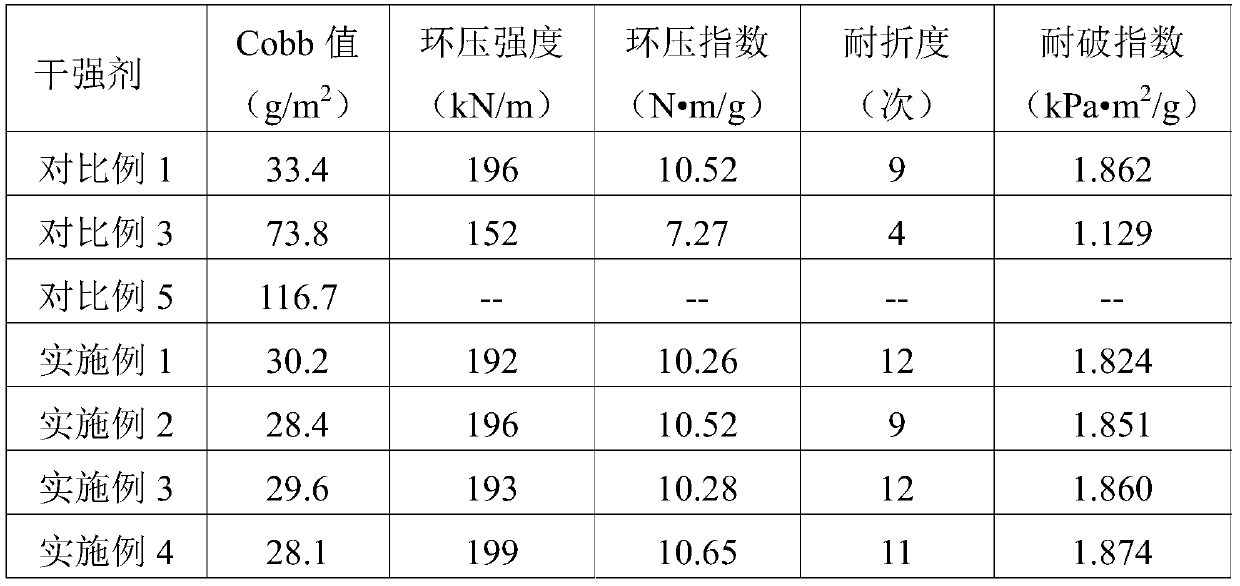

Examples

Embodiment 1

[0080] 1. Preparation of modified sizing starch

[0081] Step (1): Under the condition of stirring, add 30g of pulping waste liquid (15g in dry weight) with a solid content of 50% into the glass reactor, 70g of water and 28g of tapioca starch, mix well, and mix Start to raise the temperature, and gelatinize for 1.5 hours at a temperature of 75° C. to obtain material A.

[0082] Step (2): After the gelatinization is completed, under the condition of stirring, mix the prepared material A with 0.08g of ferrous sulfide, adjust the pH of the system to 4.5 with a mass fraction of 36% hydrochloric acid, the addition of hydrochloric acid 14g; then add 5g of aqueous hydrogen peroxide solution with a mass fraction of 28% dropwise to the system for 30 minutes, after the dropwise addition, keep warm at 75-78°C for 2 hours to obtain material B.

[0083] Step (3): Under the condition of stirring, mix the prepared material B with 0.8g of sodium azide and 3g of water evenly, after mixing, co...

Embodiment 2

[0087] 1. Preparation of modified sizing starch

[0088]Step (1): Under stirring conditions, add 25g of pulping waste liquid with a solid content of 50% (12.5g in dry weight), 50g of water and 20g of cornstarch into the glass reactor, mix well, and mix After that, start to raise the temperature, and gelatinize at 80°C for 0.75h to obtain material A.

[0089] Step (2): After the gelatinization is completed, under the condition of stirring, mix the prepared material A and 0.06g of chromium monoxide evenly, and adjust the pH of the system to 5 with a mass fraction of 36% hydrochloric acid. 10.6g; add 4g of aqueous hydrogen peroxide solution with a mass fraction of 28% dropwise to the system for 20min, after the dropwise addition, keep the temperature at 78-81°C for 1.5h to obtain the material b.

[0090] Step (3): Under the condition of stirring, mix the prepared material B with 0.6g of methanol and 32g of water evenly, after mixing, cool down to room temperature and then disch...

Embodiment 3

[0094] 1. Preparation of modified sizing starch

[0095] Step (1): Under the condition of stirring, add 18g of pulping waste liquid (9g in dry weight) with a solid content of 50% to the glass reactor, 50g of water and 12g of potato starch, mix well, and mix Start to raise the temperature, and gelatinize for 1 hour at a temperature of 80° C. to obtain material A.

[0096] Step (2): After the gelatinization is completed, under the condition of stirring, mix the prepared material A with 0.04 g of vanadium dichloride evenly, adjust the pH of the system to 4.7 with a mass fraction of 36% hydrochloric acid, and add the hydrochloric acid The amount is 8g; then 2.5g of aqueous hydrogen peroxide solution with a mass fraction of 28% is added dropwise to the system for 10 minutes. b.

[0097] Step (3): Under the condition of stirring, mix the prepared material B with 0.3g of salicylic acid and 146g of water evenly, after mixing, it is cooled to room temperature and discharged to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com