High-surface-strength paper surface sizing agent

A surface sizing agent and paper technology, applied in the direction of water repellent addition, etc., can solve problems such as complex operation, achieve good biocompatibility, easy film formation, and improve surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

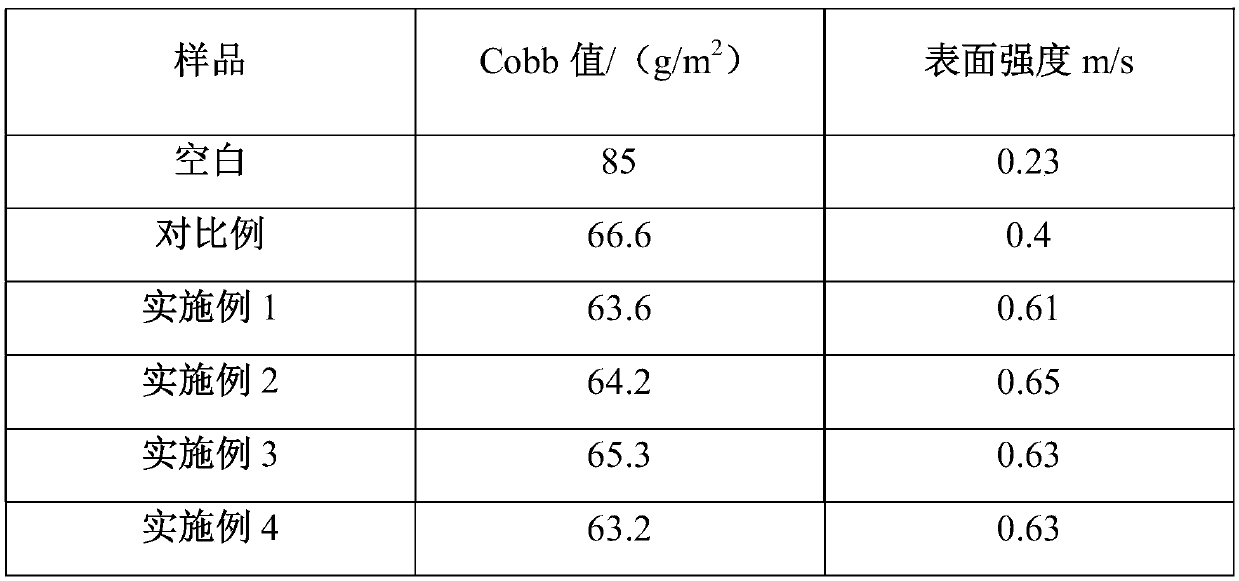

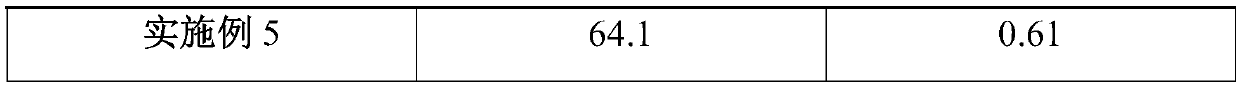

Examples

Embodiment 1

[0030] 1. Preparation of modified chitosan:

[0031] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, add 32 grams of chitosan and 200 grams of 2% acetic acid solution by mass fraction, and stir to dissolve overnight. Add 50 grams of salicylaldehyde and react at 80°C for 6h. Adjust pH=7-8, add 50 grams of 10% NaBH 4 Aqueous solution, continue to stir for 2-3h.

[0032] 2. Preparation of surface sizing agent for paper:

[0033] Add 200 grams of modified chitosan and 384 grams of deionized water to a 1000 ml four-necked flask equipped with a condenser, a dropping device, a stirrer and a thermometer, heat up to 80° C. to dissolve, and cool to 45° C. Slowly add 73 g of 25 wt % stearyl polyoxyethylene (10) ether aqueous solution dropwise, and the dropwise addition is completed within 0.5 hr. Add 24.3 g of 25 wt % glycerin aqueous solution, stir for 0.5 hr, and then filter through a 100-mesh filter to obtain a surface sizing agent w...

Embodiment 2

[0035] 1. Preparation of modified chitosan:

[0036] In a 1000ml four-necked flask with a condenser, a dropping device, a stirrer and a thermometer, add 32 grams of chitosan and 200 grams of 2% acetic acid solution by mass fraction, and stir to dissolve overnight. Add 60 grams of salicylaldehyde and react at 85°C for 6h. Adjust pH=7-8, add 70 grams of 10% NaBH 4 Aqueous solution, continue to stir for 2-3h.

[0037] 2. Preparation of surface sizing agent for paper:

[0038] Add 100 grams of modified chitosan and 265 grams of deionized water to a 1000 ml four-neck flask equipped with a condenser, a dropping device, a stirrer and a thermometer, heat up to 80° C. to dissolve, and cool to 45° C. 42.95 g of 20 wt % stearyl polyoxyethylene (15) ether aqueous solution was slowly added dropwise, and the dropwise addition was completed within 0.5 hr. Add 19.52 g of 20 wt % pentaerythritol aqueous solution, stir for 0.5 hr and filter through a 100-mesh filter to obtain a surface sizi...

Embodiment 3

[0040] 1. Preparation of modified chitosan:

[0041] In the 1000ml four-neck flask with condenser, dropping device, stirrer, thermometer, add 42 grams of chitosan, 200 grams of acetic acid solution with a mass fraction of 2%, stir and dissolve overnight. Add 60 grams of salicylaldehyde and react at 85°C for 6h. Adjust pH=7-8, add 70 grams of 10% NaBH 4 Aqueous solution, continue to stir for 2-3h.

[0042] 2. Preparation of surface sizing agent for paper:

[0043] Add 100 grams of modified chitosan and 265 grams of deionized water to a 1000 ml four-neck flask equipped with a condenser, a dropping device, a stirrer and a thermometer, heat up to 80° C. to dissolve, and cool to 45° C. 42.95 g of 20 wt% AOE-9 aqueous solution was slowly added dropwise, and the dropwise addition was completed within 0.5 hr. Add 19.52 g of 20 wt % trihydroxypropane aqueous solution, stir for 0.5 hr, and then filter through a 100-mesh filter to obtain a surface sizing agent with a pH of 2.35 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com