Surface sizing agent emulsion and its preparation method and application

A surface sizing agent and emulsion technology, which is applied in the direction of water repellent addition, non-polymer organic compound addition, wax addition, etc., can solve the problems of low retention rate, slow fiber response, long sizing curing time, etc., and achieve The effect of improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

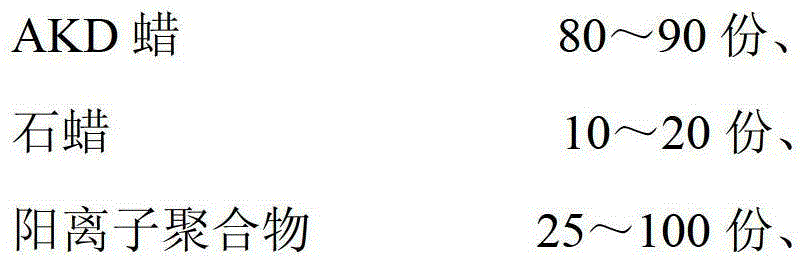

Method used

Image

Examples

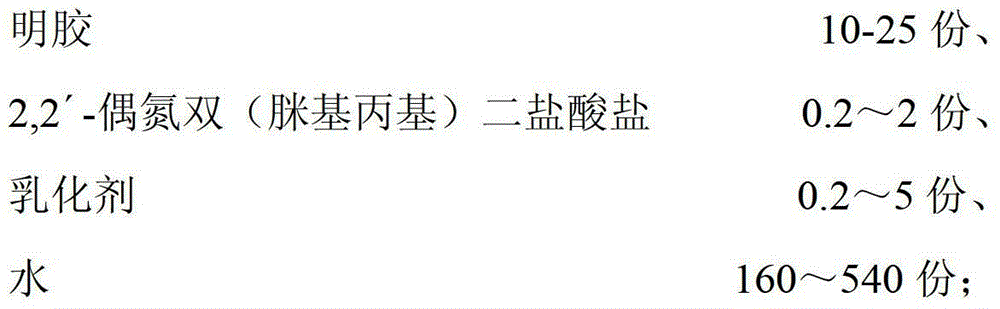

Embodiment 1

[0033] Synthesis of cationic polymers:

[0034] a) Mix 70 grams of n-butyl acrylate, 20 grams of styrene and 10 grams of dimethylaminoethyl methacrylate monochloromethane quaternary ammonium to prepare a mixed monomer for subsequent use.

[0035] b) Mix 0.2 g of octadecyl polyoxyethylene (5) trimethylammonium chloride with 10 g of deionized water, dissolve completely, and set aside.

[0036] c) Mix 0.2 g of 2,2'-azobis(amidinopropyl) dihydrochloride and 10 g of deionized water, dissolve completely, and set aside.

[0037] d) Mix 10 grams of gelatin with a molecular weight of 5000 g / mol and 145.75 grams of deionized water, and heat up to 85° C. to dissolve completely. Add the emulsifier aqueous solution in step b) and control it at 95°C, add the 2,2'-azobis(amidinopropyl)dihydrochloride aqueous solution in step c), and then add a dropwise at 95°C ) step to mix the monomers for 1 hour.

[0038] e) Incubate at 95°C for 1 hour. Cool down to 25°C and filter through a 100-mesh s...

Embodiment 2

[0044] Synthesis of cationic polymers:

[0045] a) Mix 30 grams of isooctyl acrylate, 50 grams of methyl styrene and 20 grams of dimethylaminoethyl methacrylate benzyl quaternary ammonium chloride to prepare mixed monomers, and set aside.

[0046] b) Mix 5 grams of lauryl polyoxyethylene (20) trimethylammonium chloride and 10 grams of deionized water, dissolve completely, and set aside.

[0047] c) Mix 2 grams of 2,2'-azobis(amidinopropyl) dihydrochloride and 10 grams of deionized water, dissolve completely, and set aside.

[0048] d) Mix 25 grams of gelatin with a molecular weight of 50,000 g / mol and 532 grams of deionized water, and heat up to 85° C. to dissolve completely. Add the emulsifier aqueous solution in step b) and control it at 60°C, add the 2,2'-azobis(amidinopropyl) dihydrochloride aqueous solution in step c), and then add a dropwise at 60°C ) step to mix the monomers for 3 hours.

[0049] e) Incubate at 60°C for 2 hours. Cool down to 25°C and filter through ...

Embodiment 3

[0055] Synthesis of cationic polymers:

[0056] a) Mix 30 grams of ethyl acrylate, 30 grams of methyl methacrylate, 35 grams of styrene and 5 grams of dimethylaminoethyl methacrylate monochloromethane quaternary ammonium to prepare mixed monomers, and set aside.

[0057] b) Mix 3 grams of cetyl polyoxyethylene (10) trimethylammonium chloride and 10 grams of deionized water, dissolve completely, and set aside.

[0058] c) Mix 1 gram of 2,2'-azobis(amidinopropyl) dihydrochloride and 10 grams of deionized water, dissolve completely, and set aside.

[0059] d) Mix 18 grams of gelatin with a molecular weight of 20000 g / mol and 274.5 grams of deionized water, and heat up to 85° C. to dissolve completely. Add the emulsifier aqueous solution in step b) and control it at 80°C, add the 2,2'-azobis(amidinopropyl)dihydrochloride aqueous solution in step c), and then add a dropwise at 80°C ) step to mix the monomers for 2 hours.

[0060] e) Incubate at 80°C for 1.5 hours. Cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com