Preparation and application method of water-tolerant paper surface sizing agent

A surface sizing agent and surface sizing technology, applied in the direction of water repellent addition, etc., can solve the problems of low storage stability of sizing liquid, large emulsion particle size, weak binding force, etc., and achieve the reduction of Cobb value, particle size, etc. The effect of low diameter and improved binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

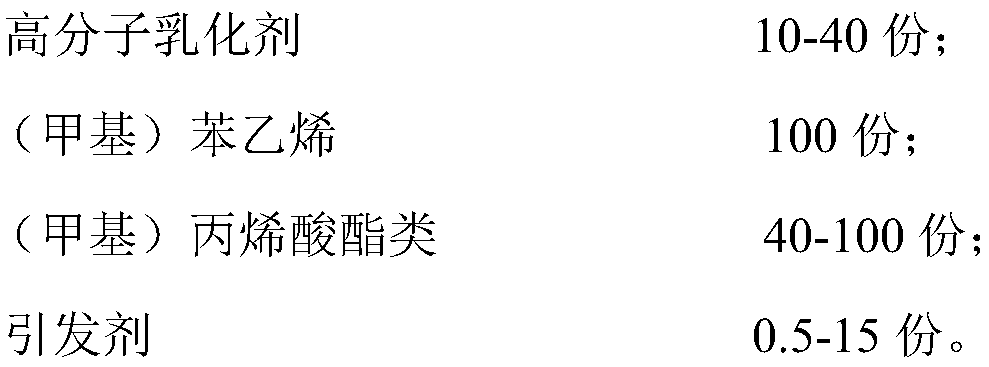

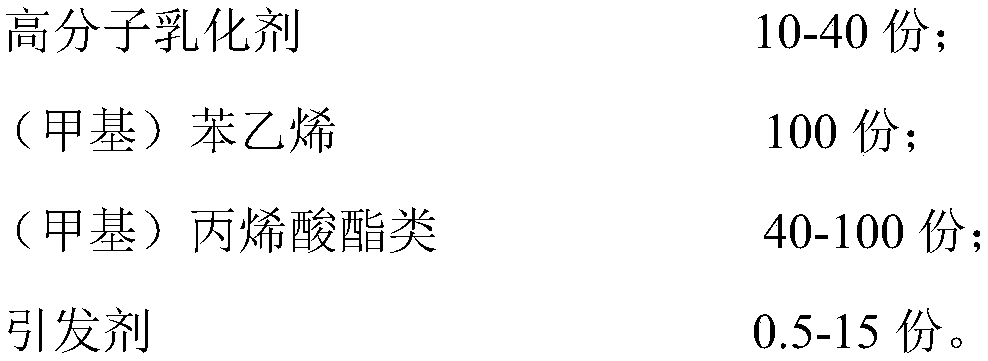

Method used

Image

Examples

Embodiment 1

[0032] Preparation of water-resistant surface sizing agent:

[0033] Mix 8 grams of polyvinyl alcohol, 180 grams of mixed monomers (100 grams of styrene, 80 grams of ethyl acrylate), and 100 grams of deionized water together, and stir at 500 rpm for 30 minutes to form a stable emulsion. 350 grams of deionized water and 2 grams of polyvinyl alcohol were added into a four-necked flask and the temperature was raised to 80° C., and 0.3 g of ammonium persulfate was added. After reacting for 10 minutes, slowly add the aforementioned emulsion dropwise, and the dropwise addition is completed in 1.5 hours. While adding the monomer dropwise, 0.7 g of ammonium persulfate and 50 g of deionized aqueous solution were added dropwise, and the drop was completed within 2 hours. After the dropwise addition was completed, the reaction was continued for 1 hr. After cooling, filter through a 325-mesh filter to obtain a surface sizing agent with a pH of 3.5 and a solid content of 27.1%.

Embodiment 2

[0035] Preparation of water-resistant surface sizing agent:

[0036] Mix 16 grams of stearyl polyoxyethylene (10) ether, 200 grams of mixed monomers (100 grams of styrene, 100 grams of butyl acrylate), and 150 grams of deionized water, and stir at 600 rpm for 30 minutes to form a stable emulsion. 400 grams of deionized water and 4 grams of octadecyl polyoxyethylene (10) ether were added into a four-necked flask and the temperature was raised to 85° C., and 0.3 g of potassium persulfate was added. After reacting for 10 minutes, slowly add the aforementioned emulsion dropwise, and the dropwise addition is completed in 1.5 hours. While adding the monomer dropwise, 0.7 g of potassium persulfate and 50 g of deionized aqueous solution were added dropwise, and the drop was completed within 2 hours. After the dropwise addition was completed, the reaction was continued for 1 hr. After cooling, filter through a 325-mesh filter screen to obtain a surface sizing agent with a pH of 3.35 ...

Embodiment 3

[0038] Preparation of water-resistant surface sizing agent:

[0039] Mix 32 grams of polyvinylpyrrolidone, 180 grams of mixed monomers (100 grams of styrene, 80 grams of isooctyl acrylate), and 150 grams of deionized water, and stir at 600 rpm for 40 minutes to form a stable emulsion. 310 grams of deionized water and 8 grams of polyvinylpyrrolidone were added into a four-necked flask and the temperature was raised to 90° C., and 0.9 g of tert-butyl peroxybenzoate was added. After reacting for 15 minutes, slowly add the aforementioned emulsion dropwise, and the dropwise addition is completed in 1.5 hours. While adding the monomer dropwise, 2.1 g of tert-butyl peroxybenzoate and 50 g of deionized aqueous solution were added dropwise, and the drop was completed within 2 hours. After the dropwise addition was completed, the reaction was continued for 1 hr. After cooling, filter through a 325-mesh filter to obtain a surface sizing agent with a pH of 3.39 and a solid content of 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com