Surface sizing agent emulsion and preparation method and application thereof

A technology of surface sizing agent and emulsion, applied in the field of emulsion, can solve the problem of reducing water resistance, and achieve the effect of improving surface strength, improving hydrophobicity and reducing Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

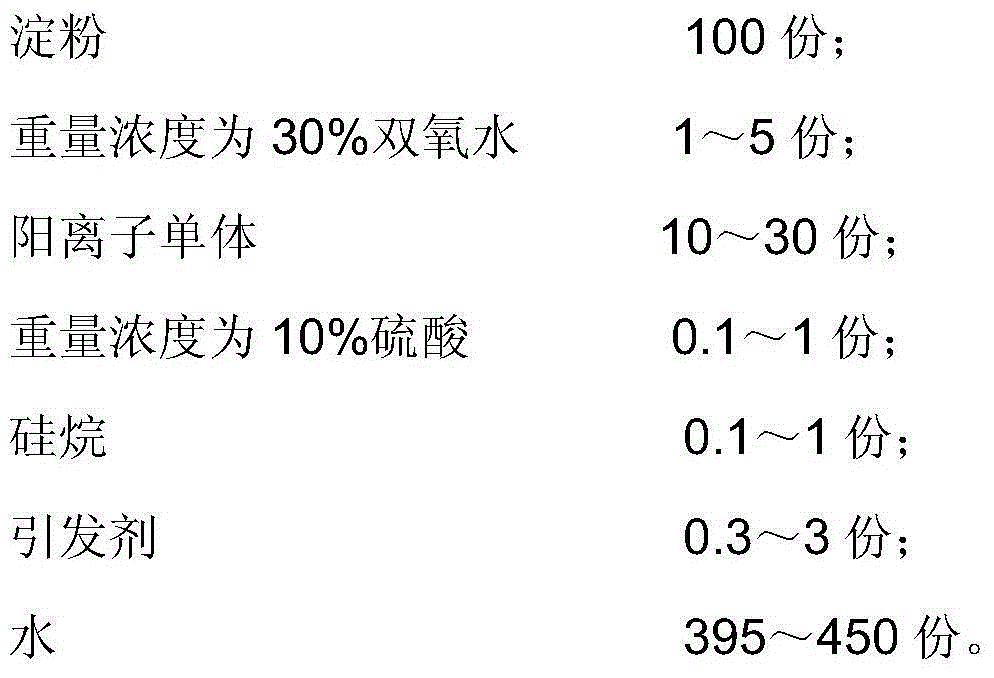

preparation example Construction

[0030] The invention provides a method for preparing a surface sizing agent emulsion, which is characterized in that the cationic polymer and water are mixed, alkenyl succinic anhydride (ASA) and paraffin are added, stirred homogeneously, and aluminum sulfate is added to obtain the The above-mentioned surface sizing agent emulsion.

[0031] Wherein, the preparation method specifically includes:

[0032] Step 1: Mix the cationic polymer and water, at 70-75°C, the stirring speed is 8000-10000rpm / min;

[0033] Step 2: Add alkenyl succinic anhydride (ASA) and paraffin, stir for 10-15 minutes, and homogenize under the condition of 10-15Mpa;

[0034] Step 3: adding aluminum sulfate and mixing evenly to obtain the surface sizing agent emulsion.

[0035] In a preferred embodiment of the present invention, the weight solid content of the surface sizing agent emulsion is 15-25%, the viscosity at 25° C. is 5-80 mPa.s, and the pH is 3-5.

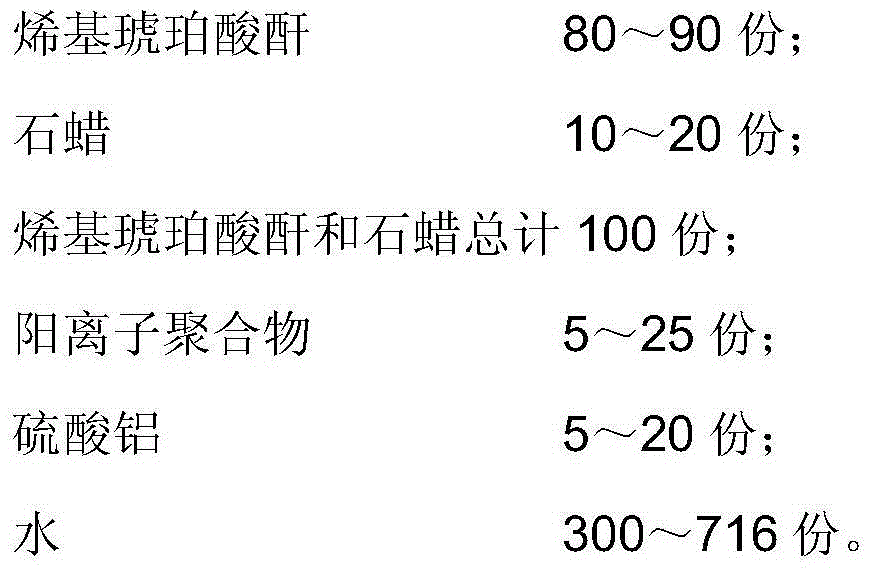

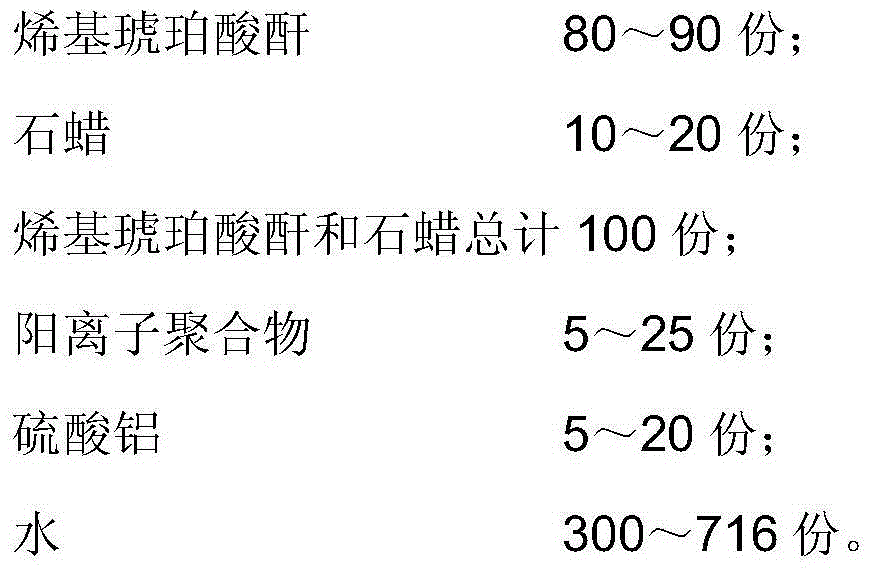

[0036] The components and weight proportions t...

Embodiment 1

[0055] 1. Preparation method of cationic polymer

[0056] a) 0.3g potassium persulfate is dissolved in 10g deionized water to be dissolved into initiator aqueous solution, for subsequent use;

[0057] b) Add 100g of cornstarch and 300g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 60°C;

[0058]c) At 60°C, add 1g of hydrogen peroxide into a four-necked flask, and keep it warm at 60°C for 1 hour; use 1g of sulfuric acid to adjust the pH to 3.02.

[0059] d) Heating up to 70°C again, quickly adding 2.06g of initiator aqueous solution into a four-necked flask, and incubating at 70°C for 10 minutes; at the same time, dropwise adding 10g of dimethyl diallyl ammonium chloride and the remaining amount of initiator aqueous solution, dropwise The adding time is 1 hour; then 0.1 g of vinyltriisopropoxysilane is added dropwise, and the dropping time is 15 minutes.

[0060] e) 1 hour at 70° C., add 130.1 g of deionized water, cool to 25° C. and filter to obt...

Embodiment 2

[0066] 1. Preparation method of cationic polymer

[0067] a) 3g of sodium persulfate is dissolved in 10g of deionized water to form an aqueous initiator solution. spare;

[0068] b) Add 100g of tapioca starch and 300g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 70°C;

[0069] c) At 70°C, 5g of hydrogen peroxide was added into a four-necked flask, and kept at 70°C for 3 hours; pH was adjusted to 4.91 with 0.1g of sulfuric acid.

[0070] d) Heating up to 90°C again, quickly adding 3.9g of the initiator aqueous solution into the four-necked flask, and incubating at 90°C for 5 minutes; at the same time, dropwise adding 30g of methacrylic acid acyloxyethyltrimethylammonium chloride and the remaining amount of the initiator The aqueous solution was added dropwise for 3 hours; then 1 g of γ-methacryloxypropyltrimethoxysilane was added dropwise for 5 minutes.

[0071] e) 90°C insulation for 0.5 hour, add 92.08g deionized water, cool to 25°C and filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com