High-performance sizing agent emulsion and preparation method thereof

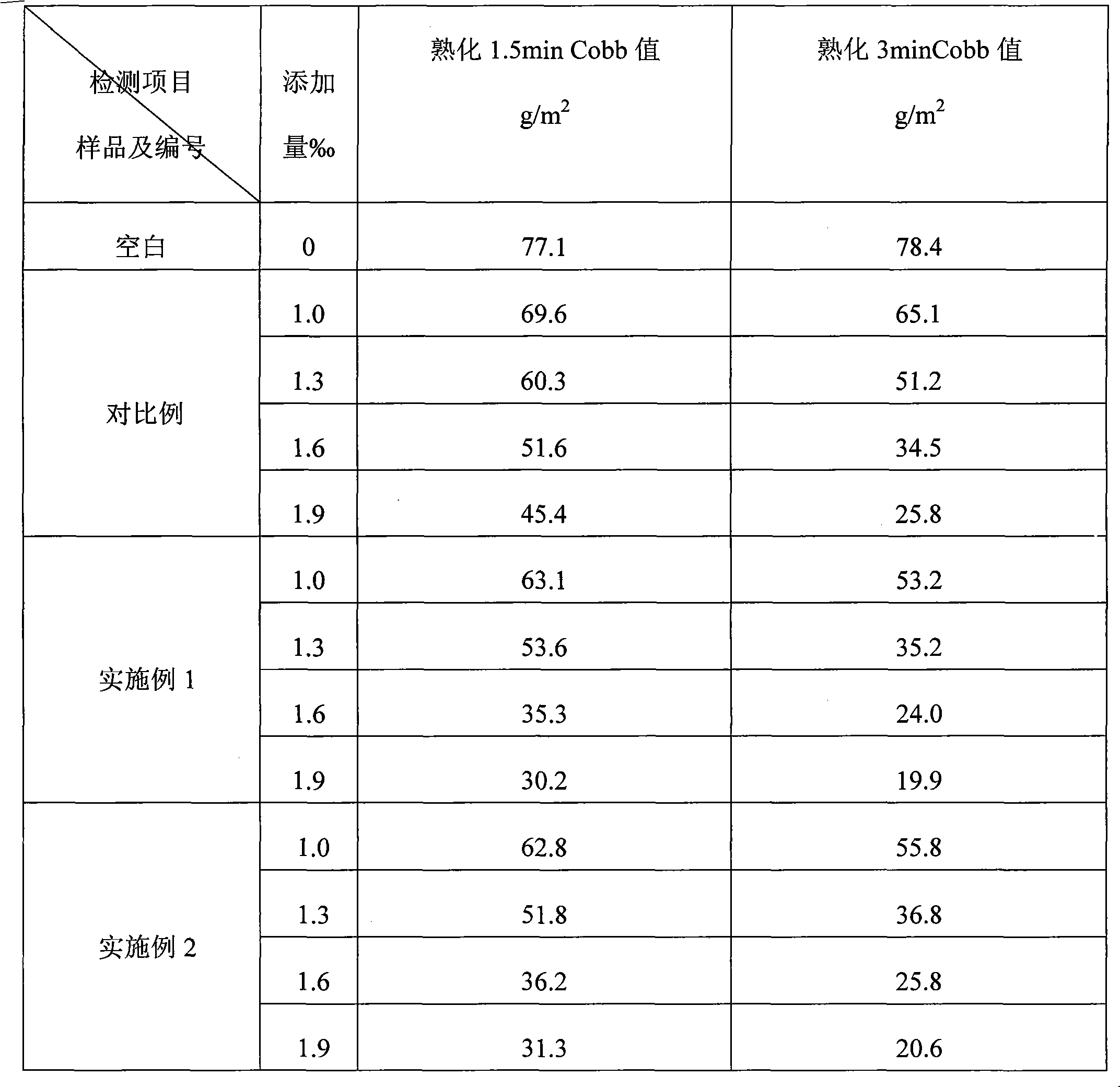

A sizing agent and high-performance technology, which is applied in the direction of water-repellent agent addition, textile and papermaking, fiber raw material treatment, etc., can solve the problem of large amount of sizing agent, achieve the effect of improving hydrophobicity and reducing Cobb value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

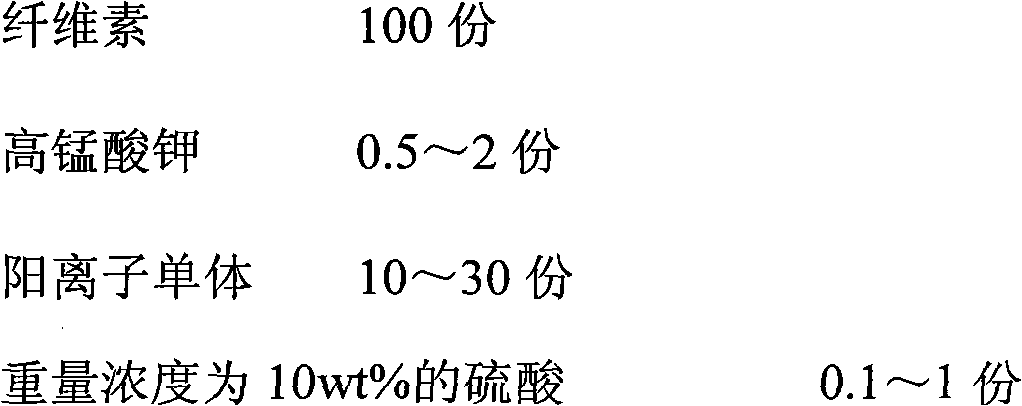

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of cationic polymers:

[0030] a) 0.3g potassium persulfate is dissolved in 10g deionized water to be dissolved into an aqueous initiator solution, for subsequent use; 0.5g potassium permanganate is dissolved in 1.17g deionized water to be dissolved into an aqueous solution of potassium permanganate;

[0031] b) Add 100g of hydroxyethyl cellulose and 300g of deionized water into a 1000ml four-neck flask, dissolve, and heat up to 60°C;

[0032] c) At 60°C, add the potassium permanganate aqueous solution in step a) into a four-necked flask, and keep it warm at 60°C for 1 hour; adjust the pH to 3.05 with 1 g of sulfuric acid.

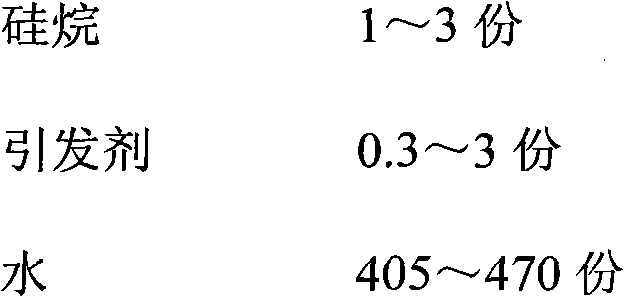

[0033] d) Heating up to 70°C again, quickly adding 2.06g of initiator aqueous solution into a four-necked flask, and incubating at 70°C for 10 minutes; at the same time, dropwise adding 10g of dimethyl diallyl ammonium chloride and the remaining amount of initiator aqueous solution, dropwise The adding time is 1 hour; then 1 g of vinyltri...

Embodiment 2

[0040] Synthesis of cationic polymers:

[0041] a) 3g sodium persulfate is dissolved in 10g deionized water to be dissolved into initiator aqueous solution, for subsequent use; 2g potassium permanganate is dissolved in 8g deionized water to be dissolved into potassium permanganate aqueous solution;

[0042] b) Add 100g carboxymethylcellulose and 400g deionized water into a 1000ml four-neck flask, dissolve, and heat up to 70°C;

[0043] c) At 70°C, add the potassium permanganate aqueous solution in step a) into a four-necked flask, and keep it warm at 70°C for 3 hours; use 0.1 g of sulfuric acid to adjust the pH to 4.95.

[0044] d) Heating up to 90°C again, quickly adding 3.9g of the initiator aqueous solution into the four-necked flask, and incubating at 90°C for 5 minutes; at the same time, dropwise adding 30g of methacrylic acid acyloxyethyltrimethylammonium chloride and the remaining amount of the initiator The aqueous solution was added dropwise for 3 hours; then 3 g of ...

Embodiment 3

[0051] Synthesis of cationic polymers:

[0052] a) 2g ammonium persulfate is dissolved in 10g deionized water to be dissolved into an aqueous initiator solution, for subsequent use; 1g potassium permanganate is dissolved in 1.5g deionized water to be dissolved into an aqueous solution of potassium permanganate;

[0053]b) Add 100g carboxymethylcellulose and 150g deionized water into a 1000ml four-neck flask, dissolve, and heat up to 65°C;

[0054] c) At 65°C, add the potassium permanganate aqueous solution in step a) into a four-necked flask, and keep it warm at 65°C for 2 hours; adjust the pH to 4.18 with 0.5 g of sulfuric acid.

[0055] d) Heating up to 80°C again, quickly adding 3g of the initiator aqueous solution into the four-necked flask, and incubating at 80°C for 8 minutes; at the same time, dropwise adding 20g of methacrylic acid acyloxyethyltrimethylammonium chloride and the remaining amount of the initiator aqueous solution , The dropping time was 2 hours; then 2g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com