A steam food processor

A food processor and steam technology, applied in steam cooking utensils, plug-ins, etc., can solve problems such as temperature attenuation and lower heating efficiency, and achieve the effects of less condensed water, good taste, and reduced heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

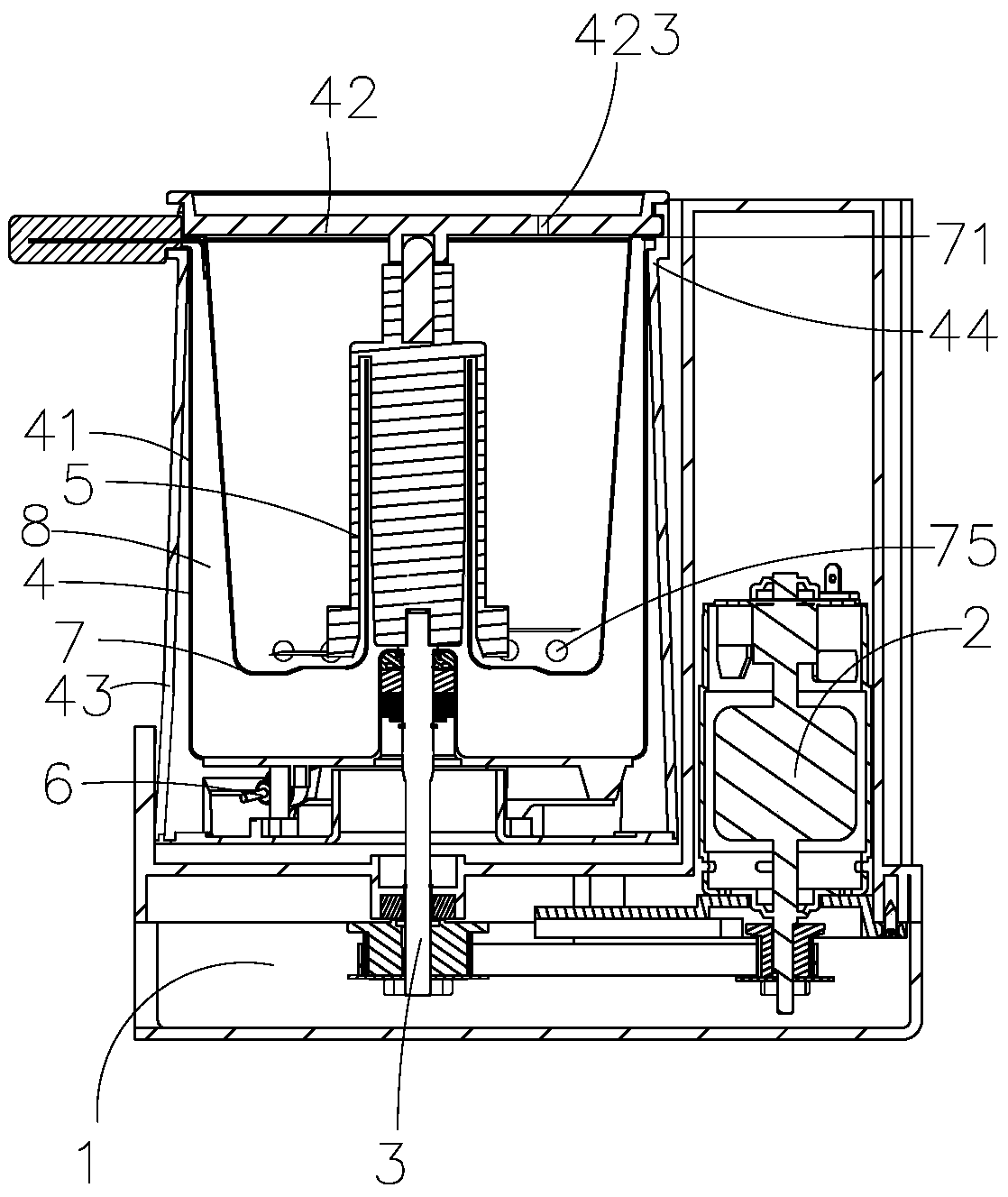

[0032] refer to figure 1 The above is the first embodiment of the present invention. A steam food processing machine includes a machine base 1, a motor 2, an output shaft 3, an outer cup 4, a crushing knife 5, and a steam generating device 6. The motor 2 is arranged in the machine base 1. The motor 2 drives the output shaft 3 to rotate through the pulley, the outer cup 4 is arranged on the machine base 1, the inner cup 7 is arranged in the outer cup 4, the crushing knife 5 is arranged in the inner cup 7, the output shaft 3 and the crushing knife 5 are detachable connect.

[0033] see figure 1 As shown, the outer cup 4 is directly fixed on the machine base 1, the outer cup 4 and the machine base 1 cannot be disassembled, and the outer cup 4 is also provided with a shell 43, and the outer cup 4 further includes an outer cup body 41 and an upper Cover 42, the outer cup body 41 is closed by the upper cover 42, the upper cover 42 is also provided with a steam discharge channel 42...

Embodiment 2

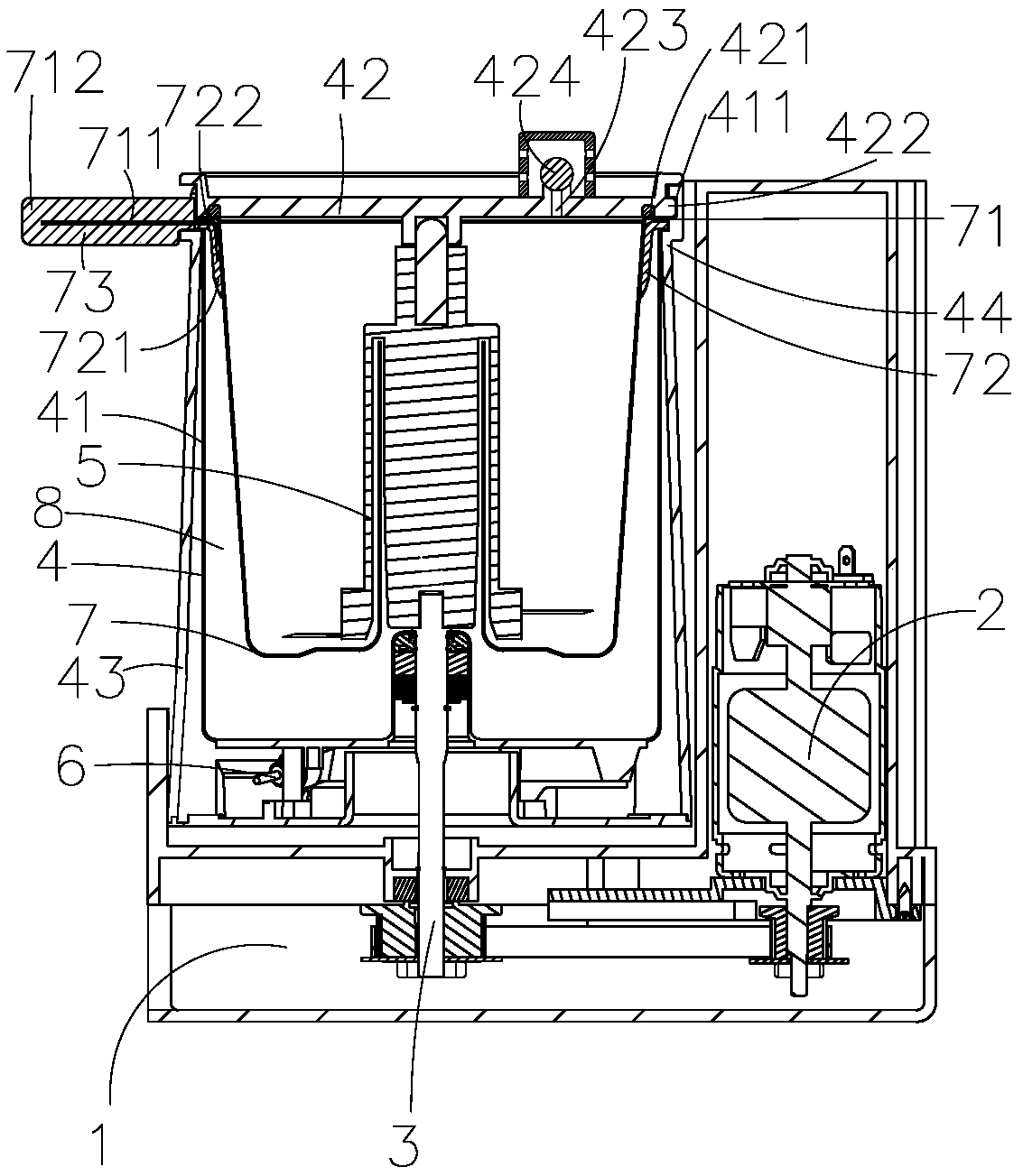

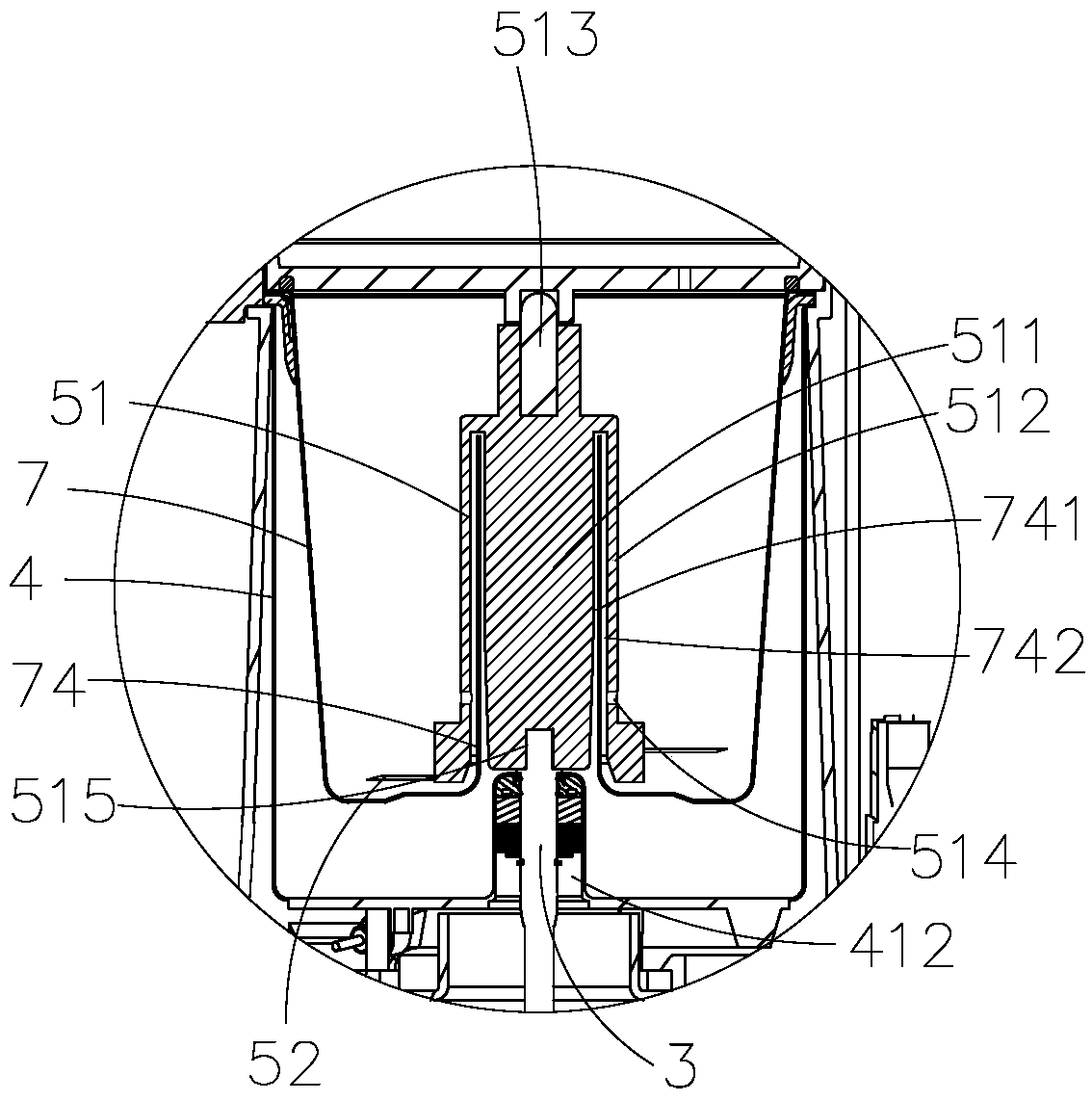

[0045] Such as Figures 2 to 3 The above is the second embodiment of the present invention, and the difference from the first embodiment is that: the inner cup 7 and the outer cup 4 are sealed and connected, and the outer side wall of the inner cup 7 is provided with a sealing ring 72, Here, the sealing ring 72 includes a vertical portion 721 and a transverse portion 722. The vertical portion 721 is attached to the outside of the side wall of the inner cup 7, so that the sealing ring 72 can be tightened on the inner cup 7. The transverse portion 722 is attached to the flange 71. Together, the transverse portion 722 is also provided with a plurality of lips, and the lips fit onto the step 44 to form a sealed connection between the inner cup 7 and the outer cup 4 .

[0046] In this example, adopt the sealed connection between the outer cup 4 and the inner cup 7, the interlayer region 8 can be in a sealed state, and the pressure generated by the sealing makes the boiling point in...

Embodiment 3

[0055] refer to Figure 4 Described is the third embodiment of the present invention, the difference from the above-mentioned embodiment is: the outer cup 4 and the inner cup 7 are detachably connected, and the outer cup body 41 is provided with a step 44, where the step 44 is located The lower half of the outer cup 41 has a certain distance from the bottom of the outer cup 41. The bottom of the inner cup 7 is placed on the step 44, and the outer side of the inner cup 7 is provided with a sealing ring 72 The sealing ring 72 is sleeved at the corner of the side wall of the inner cup 7 and the bottom of the cup. The sealing ring 72 includes a bottom surface sealing part 721 fitted with the step 44 and a side sealing part 722 fitted with the inner wall of the outer cup body 41. The outer cup 4 and the inner cup 7 are installed at intervals so as to form a sandwich area 8 for holding water.

[0056] In this example, the sealing ring 72 provided at the bottom of the inner cup 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com