Water-resistant and moisture-proof method for corrugated base paper

A corrugated base paper and pulp technology, applied in the field of papermaking, can solve problems such as waste, affecting papermaking costs, and increasing the sewage treatment load of paper mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A water-proof and moisture-proof method for corrugated base paper in this embodiment comprises the following steps:

[0025] Step 1: Prepare pulp with 100% domestic waste as raw material, and then use breast rolls with stable frequency and amplitude in the dehydration stage of the wire section to distribute the paper fibers in the pulp evenly on the wire of the wire section, and complete the pulp The first uniformity improvement treatment, and then use the adjustable angle or height of the wiper, by adjusting the height or angle of the wiper, to ensure that the slurry in the wire part jumps in the forming stage, that is, to complete the first stage of the pulp. Secondary formation improvement treatment to obtain corrugated base paper with a grammage of 80-120gsm after the second formation improvement treatment.

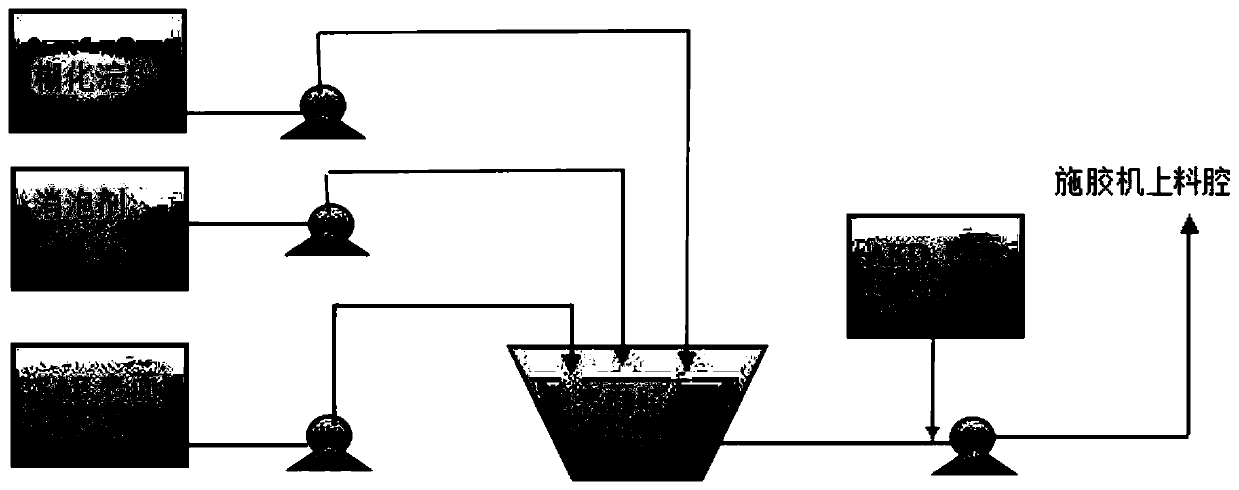

[0026] Step 2: See figure 1 , the starch with a concentration of 20-22% is gelatinized by biological amylase to obtain gelatinized starch, and then gelatinize...

Embodiment 2

[0031] A kind of corrugated base paper water-proof and moisture-proof method of this implementation is basically the same as embodiment 1, and its difference is:

[0032] In step 2, the amount of gelatinized starch is 58kg / ton of paper, defoamer is 0.04kg / ton of paper, aluminum sulfate is 1.3kg / ton of paper, SAE surface sizing agent is 3.8kg / ton of paper and AKD surface sizing agent It is 2.4kg / ton of paper.

[0033] In step 3, the dryness of the corrugated base paper entering the sizing machine is 88%, and the sizing temperature is 90°C.

Embodiment 3

[0035] A kind of corrugated base paper water-proof and moisture-proof method of this implementation is basically the same as embodiment 1, and its difference is:

[0036] In step 2, gelatinized starch is 35kg / ton of paper, defoamer is 0.06kg / ton of paper, aluminum sulfate is 1.6kg / ton of paper, SAE surface sizing agent is 4.5kg / ton of paper and AKD surface sizing agent is 3.2kg / ton of paper.

[0037] In step 3, the dryness of the corrugated base paper entering the sizing machine is 90%, and the sizing temperature is 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Water absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com