Method for producing qualified calcium superphosphate fertilizer with low-grade phosphate ore

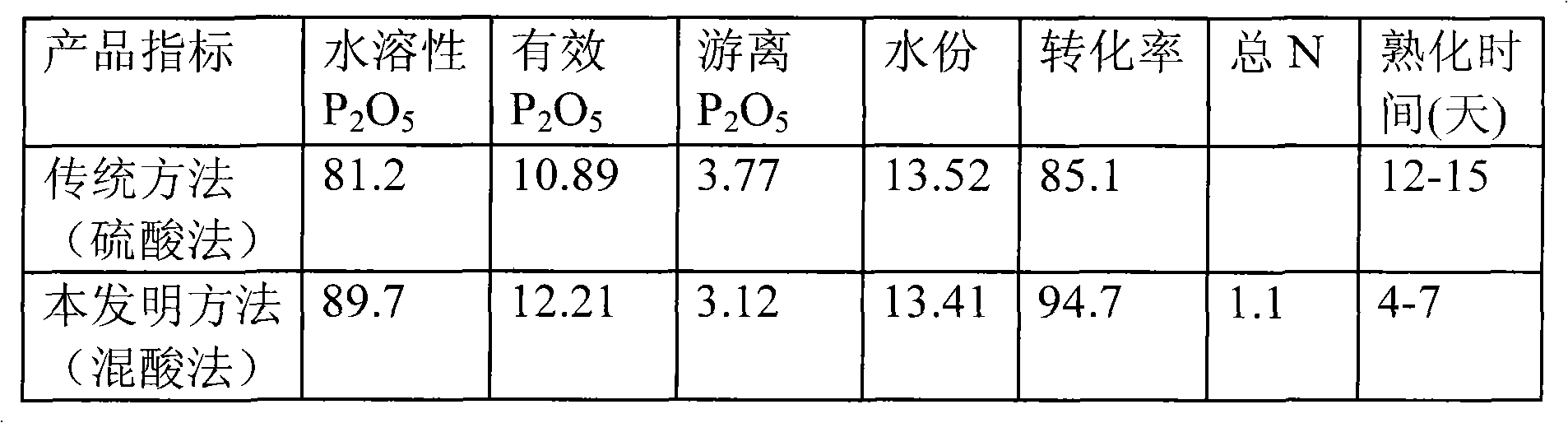

A technology for producing qualified superphosphate and low-grade superphosphate, applied in the direction of superphosphate, phosphate fertilizer, application, etc., to achieve the effect of improving the utilization rate of fertilizer, reducing production cost, and speeding up curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) pulp preparation: P 2 o 5 Phosphate rock with a content of 22-23% is crushed in two stages, and the particle size is controlled below 30mm. Measured according to dry matter, 100 parts of phosphate rock powder are sent to a ball mill and wet-milled with water to make the particle size ≥ 90 mesh, and ensure the water content 26%;

[0039] (2) Preparation of mixed acid: Take 45 parts of concentrated sulfuric acid and 15 parts of concentrated nitric acid, mix the two in the mixed acid pool, and cool the mixed acid to 100-110°C;

[0040](3) Preparation of superphosphate phosphate fertilizer: Place the above-mentioned phosphate rock slurry in a mixer, add the above-mentioned mixed acid under stirring, the acid addition process is generally 4 minutes, adjust the free acid concentration in the system to 17-20 %, transfer the mixed slurry from the discharge port of the mixer into the chemical conversion chamber, and keep the chemical conversion in the chemical conversion r...

Embodiment 2

[0042] (1) pulp preparation: complete according to the step (1) in embodiment 1;

[0043] (2) Preparation of mixed acid: take 50 parts of concentrated sulfuric acid and 10 parts of concentrated nitric acid, mix the two in the mixed acid pool, and cool the mixed acid to 100-110°C;

[0044] (3) Preparation of superphosphate phosphate fertilizer: complete according to step (3) of Example 1.

Embodiment 3

[0046] (1) pulp preparation: complete according to the step (1) in embodiment 1;

[0047] (2) Preparation of mixed acid: Take 55 parts of concentrated sulfuric acid and 5 parts of concentrated nitric acid, mix the two in the mixed acid pool, and cool the mixed acid to 100-110°C;

[0048] (3) Preparation of superphosphate phosphate fertilizer: complete according to step (3) of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com