Surface sizing agent for paperboard and preparation method thereof

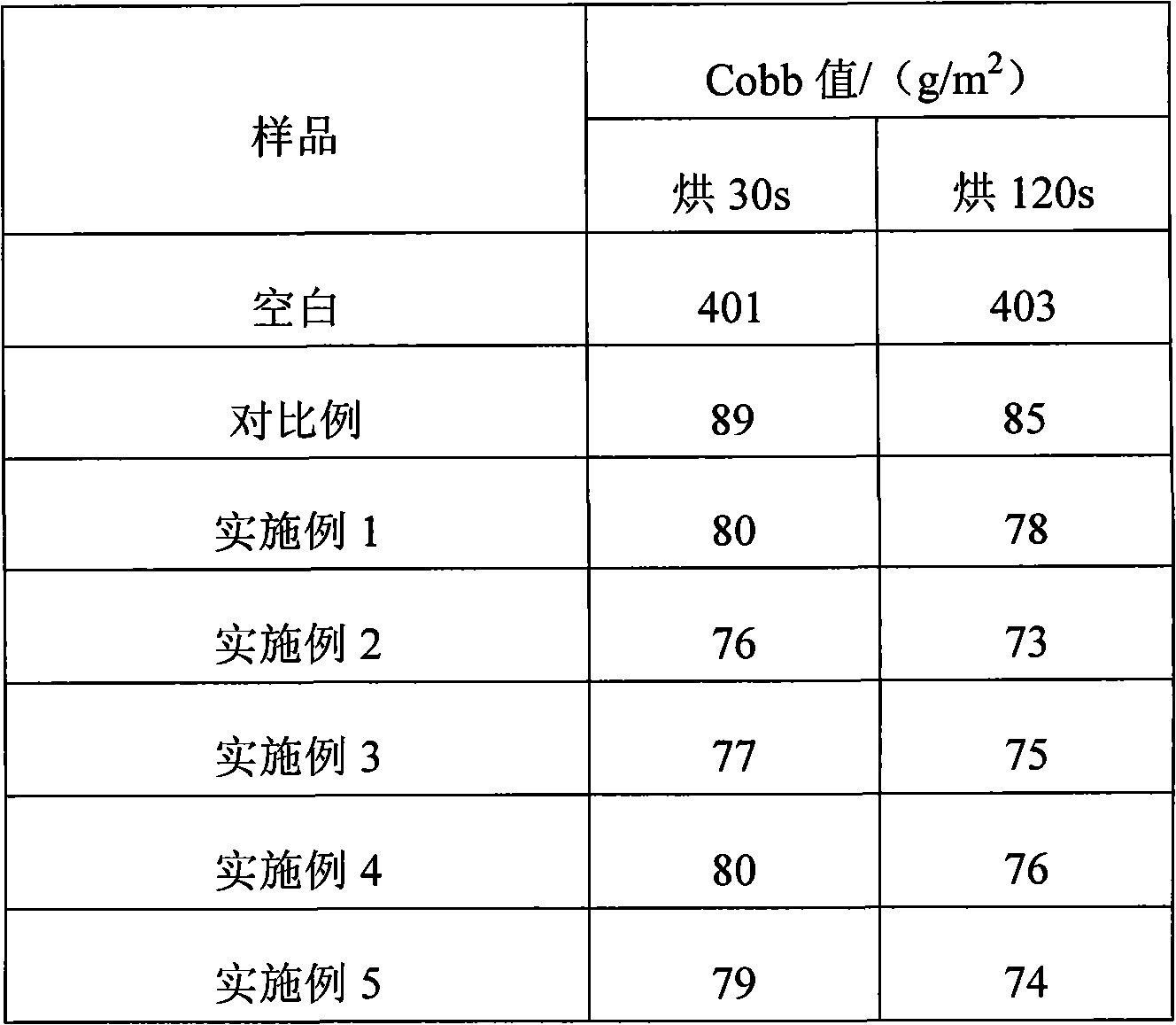

A surface sizing agent and cardboard technology, applied in the direction of water repellent addition, etc., can solve the problems of unstable paper quality, large amount of sizing agent, and difficulty in improving the grade, so as to reduce the Cobb value, reduce the dosage, and reduce the grammage. heavy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of surface sizing agent base material for cardboard:

[0045] In a 1000ml four-necked flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 20 grams of gelatin with a molecular weight of 10000 g / mol and 214.5 grams of deionized water, heat up to 85°C to dissolve, then cool down to 45°C. Add 2 grams of 25wt% octadecyl polyoxyethylene (15) trimethylammonium chloride aqueous solution, heat to 95°C, add 1.5 grams of 20wt% ammonium persulfate aqueous solution, add dropwise the following mixed monomers: 100 grams of styrene, 3 grams of dimethylaminoethyl acrylate monochloromethane quaternary ammonium, 1 gram of N-butoxymethacrylic acid, and 20 grams of n-butyl acrylate were added in 1 hour. The reaction was maintained at 95°C for 1 hour, cooled to 35°C, pH = 2.0. Filter through a 100-mesh filter screen to obtain a surface sizing agent base material for cardboard, with a solid content of 39.9 wt%.

[0046] 2. Preparation of catio...

Embodiment 2

[0053] 1. Preparation of surface sizing agent base material for cardboard:

[0054]Add 50 grams of gelatin with a molecular weight of 100,000 g / mol and 808 grams of deionized water into a 2000ml four-neck flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, heat up to 85°C to dissolve, and cool down to 45°C. Add 20 grams of 10wt% lauryl polyoxyethylene (20) trimethylammonium chloride aqueous solution, add 4 grams of 50wt% potassium persulfate aqueous solution, and drop the following mixed monomers: 100 grams of methyl styrene, methacrylic acid 8 grams of acyloxyethyltrimethylammonium chloride, 5 grams of divinylbenzene, and 40 grams of isooctyl methacrylate were added in 6 hours. The reaction was maintained at 40°C for 2 hours, cooled to 25°C, pH=5.85. Filter through a 100-mesh filter screen to obtain a surface sizing agent base material for cardboard, with a solid content of 20.1 wt%.

[0055] 2. Preparation of cationic additives:

[0056] 1) A...

Embodiment 3

[0062] 1. Preparation of surface sizing agent base material for cardboard:

[0063] In a 1000ml four-neck flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 35 grams of gelatin with a molecular weight of 80000g / mol and 395.3 grams of distilled water, and heat up to 85°C to dissolve. Cool down to 45°C. Add 10 grams of 10 wt% tetradecyl polyoxyethylene (8) trimethylammonium chloride aqueous solution, heat to 60 ° C, add 5 grams of 20 wt % sodium persulfate aqueous solution, and drop the following mixed monomers: 100 grams of styrene, 5 grams of diallyl dimethyl ammonium chloride, 3 grams of aminoethyl acrylate, and 30 grams of methyl methacrylate were added in 4 hours. The reaction was maintained at 60°C for 2 hours, cooled to 35°C, pH = 3.5. Filter through a 100-mesh filter to obtain a surface sizing agent base material for cardboard, with a solid content of 30.2 wt%.

[0064] 2. Preparation of cationic additives:

[0065] 1) Add 90g of par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com