Copper clad base plate and preparation method thereof

A technology of copper clad substrate and copper foil, which is applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of reducing the peeling strength of copper clad laminate copper foil, poor heat resistance, etc., and achieve improved reliability and electrical performance of the substrate The effect of lowering and lowering the coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

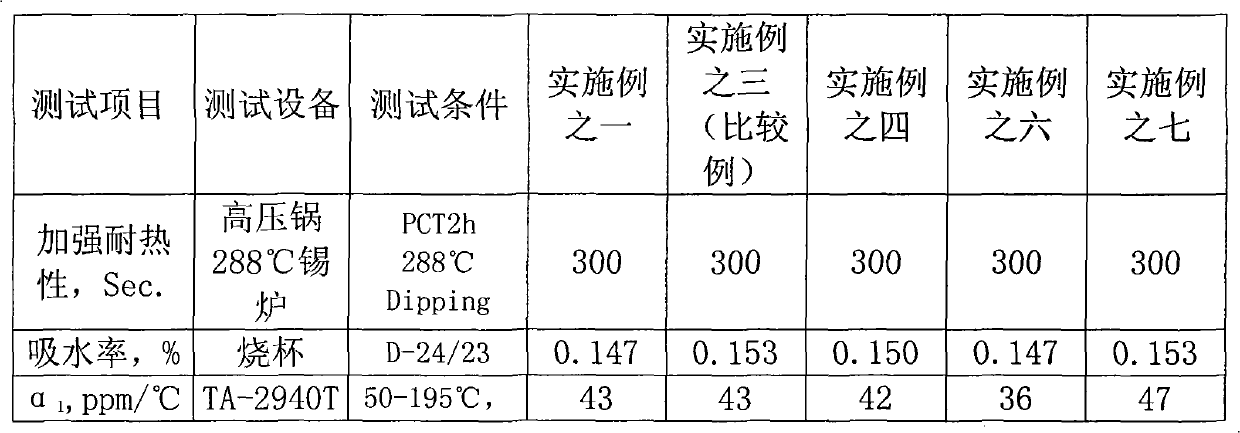

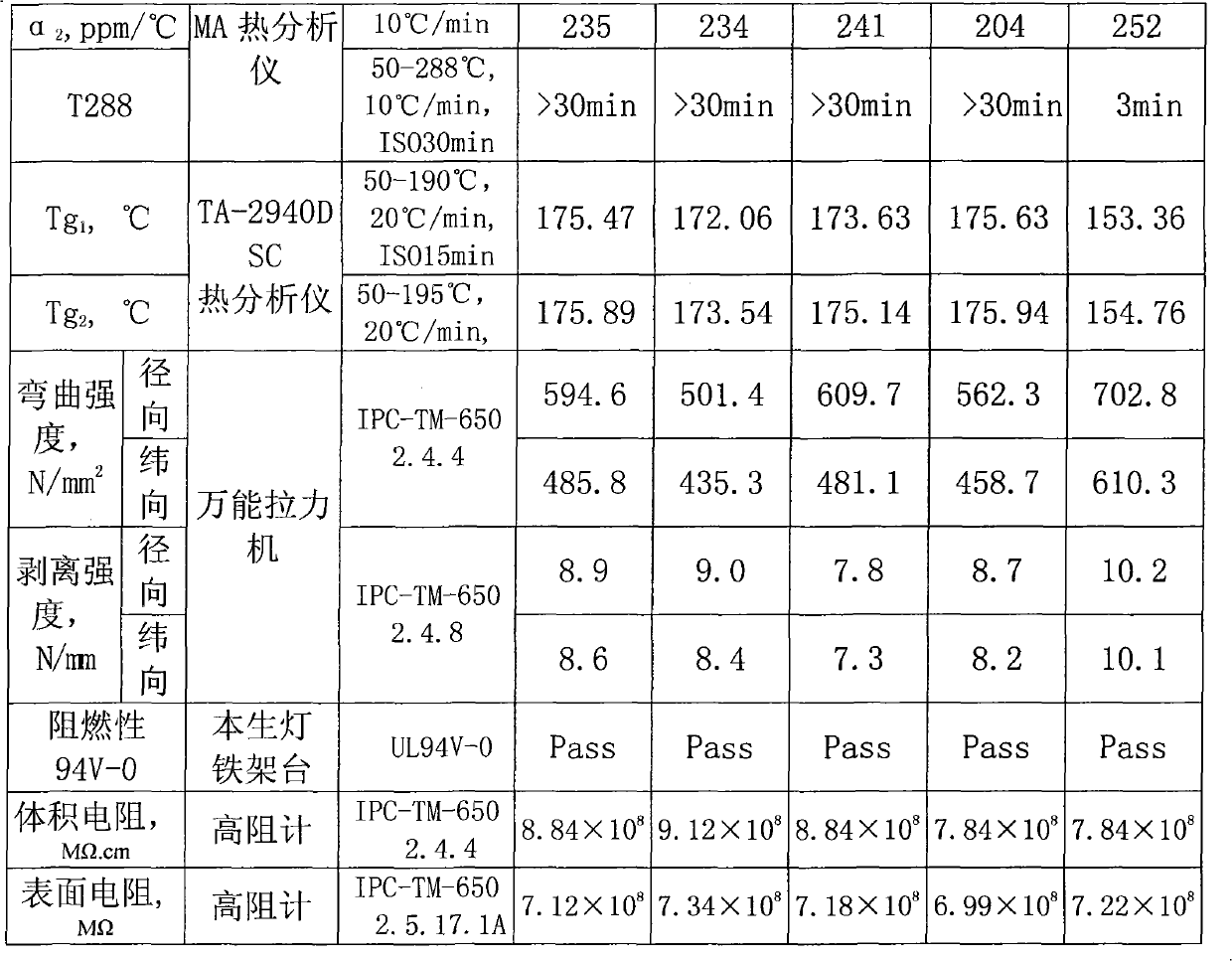

[0028] 1, specific embodiment formula

[0029] Embodiment 1 XUS19074 (the epoxy resin produced by Dow Chemical, possesses Tg of 170° C. after curing) 49.5%, curing agent 3363 (novolac resin produced by Hansen) 16.5%, propylene glycol methyl ether 22.0%, curing accelerator 0.3% of 2-ethyl-4-methylimidazole, 11.7% of G2-C (composite quartz powder produced by Sibick Company).

[0030] Embodiment 2 (comparative example) XUS19074 (an epoxy resin produced by Dow Chemical, with a Tg of 170°C after curing) 49.5%, curing agent 3363 (novolac resin produced by Hansen) 16.5%, propylene glycol methyl ether 22.0% , curing accelerator 2-ethyl-4-methylimidazole 0.3%, 925 (Silica produced by Sibic Corporation) 11.7%.

[0031] Embodiment 3 (comparative example) XUS19074 (an epoxy resin produced by Dow Chemical, with a Tg of 170°C after curing) 49.5%, curing agent 3363 (novolac resin produced by Hansen) 16.5%, propylene glycol methyl ether 22.0% , curing accelerator 2-ethyl-4-methylimidazole 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com