High impact polystyrene resin material with excellent glossiness and preparation method thereof

A technology of polystyrene resin and general-purpose polystyrene, which is applied in the field of high-impact polystyrene resin materials and its preparation, can solve the problems of HIPS poor gloss, relatively expensive price, and affect material performance, and achieve performance impact Good, good appearance gloss, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Mix 90 parts of HIPS HP8250, 10 parts of GPPS PG-22, 0.3 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2, mass ratio) and 0.1 part of EBS by high-speed stirring;

[0034] (2) Send the above mixture into the extruder, fully melt and compound under the conveying and shearing action of the screw, and then extrude through the machine head, draw, cool, pelletize, and finally pack.

[0035] The screw temperature of each section of the twin-screw extruder is controlled between 220-230°C, and the screw speed is 400 rpm.

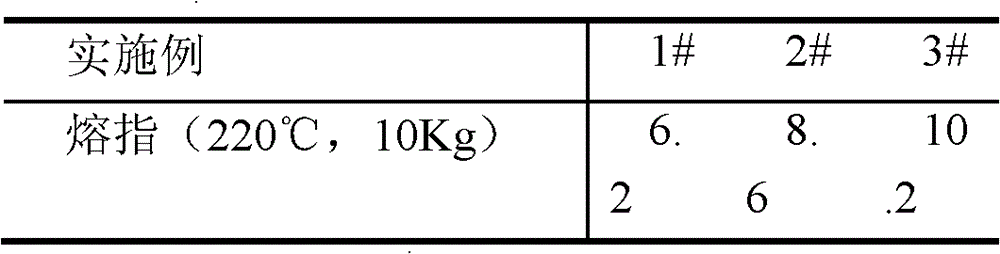

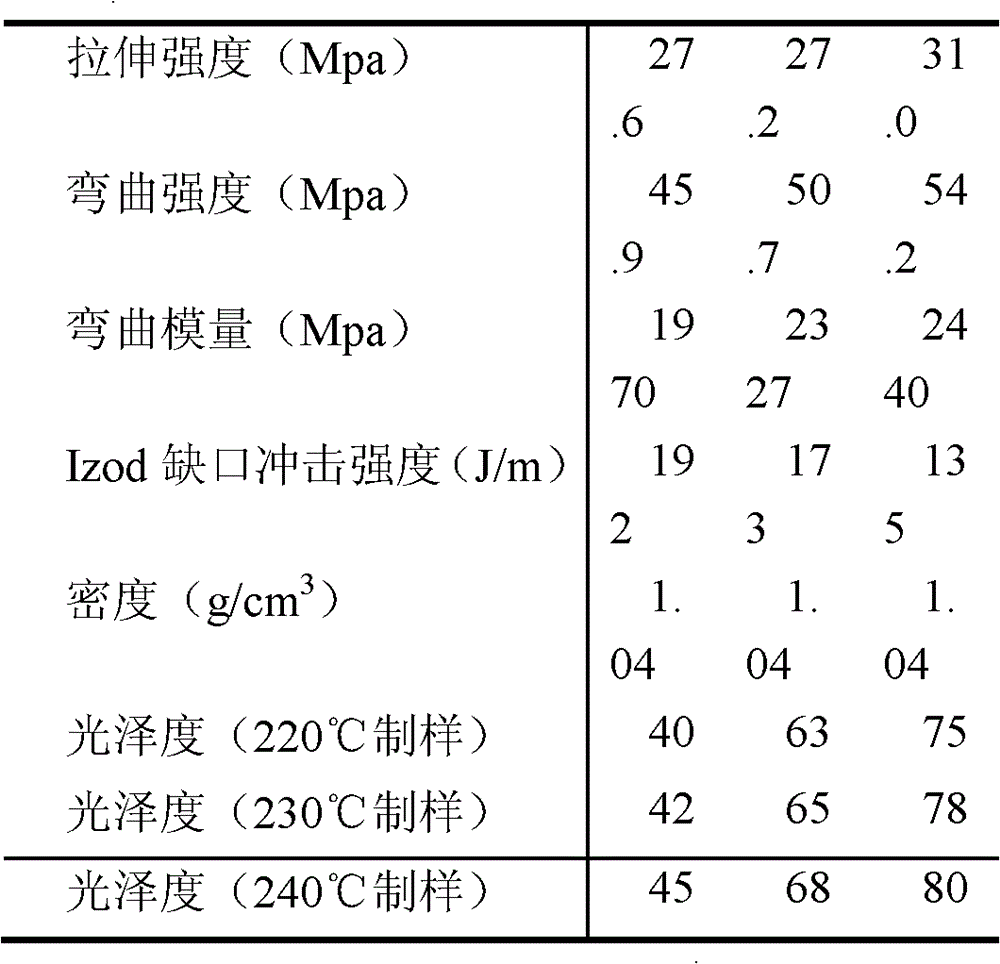

[0036] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

[0037] The prepared compound was punched into a prototype through a mold (the temperature of the mold was between 70°C and 80°C, and the temperature of each zone of the injection molding machine was between 220°C and 240°C), and its specular gloss was tested...

Embodiment 2

[0039] (1) Mix 70 parts of HIPS HP8250, 30 parts of GPPS PG-22, 0.3 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2, mass ratio) and 0.5 part of EBS by high-speed stirring;

[0040] (2) Send the above mixture into the extruder, fully melt and compound under the conveying and shearing action of the screw, and then extrude through the machine head, draw, cool, pelletize, and finally pack.

[0041] The screw temperature of each section of the twin-screw extruder is controlled between 220-230°C, and the screw speed is 400 rpm.

[0042] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

[0043] The prepared compound was punched into a prototype through a mold (the temperature of the mold was between 70°C and 80°C, and the temperature of each zone of the injection molding machine was between 220°C and 240°C), and its specular gloss was tested...

Embodiment 3

[0045] (1) Mix 50 parts of HIPS HP8250, 50 parts of GPPS PG-22, 0.3 part of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2, mass ratio) and 1.0 part of EBS by high-speed stirring;

[0046] (2) Send the above mixture into the extruder, fully melt and compound under the conveying and shearing action of the screw, then extrude through the machine head, draw, cool, pelletize, and finally pack.

[0047] The screw temperature of each section of the twin-screw extruder is controlled between 220-230°C, and the screw speed is 400 rpm.

[0048] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

[0049] The prepared compound was punched into a prototype through a mold (the temperature of the mold was between 70°C and 80°C, and the temperature of each zone of the injection molding machine was between 220°C and 240°C), and its specular gloss was tested, as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com