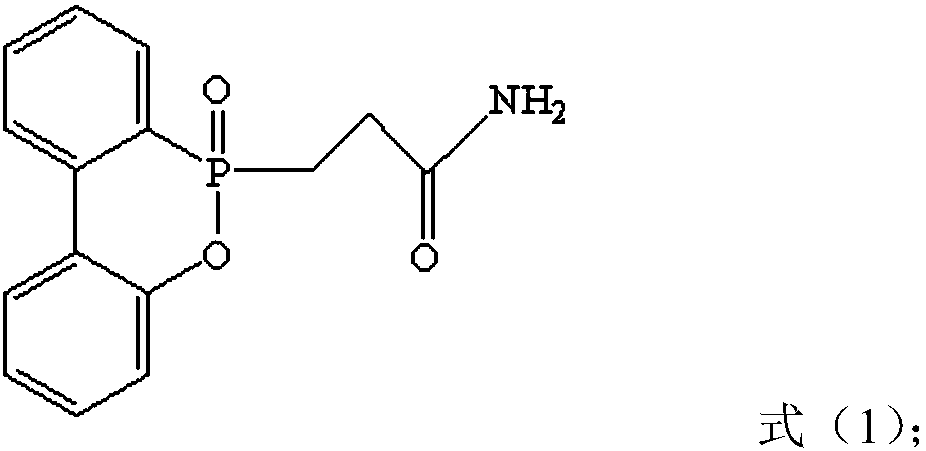

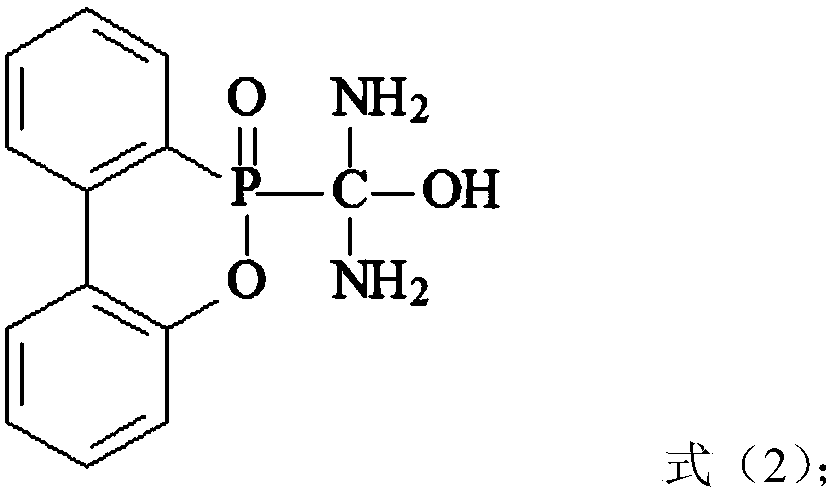

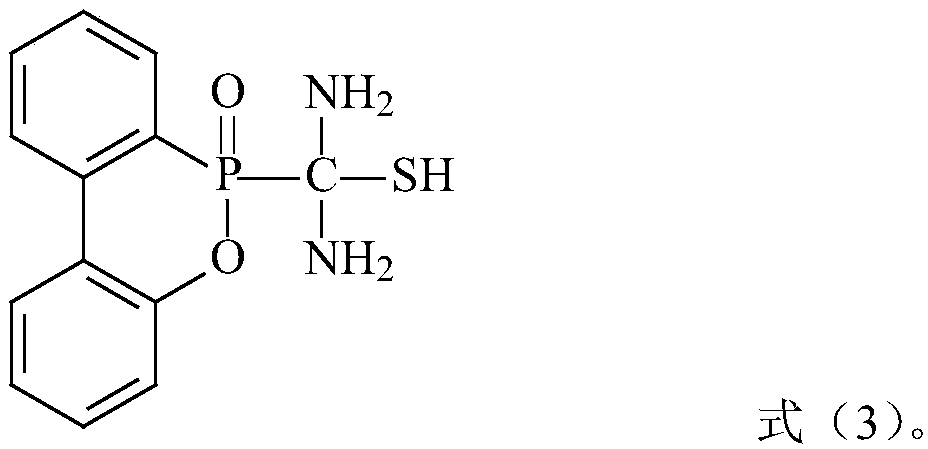

Reactive flame retardant for epoxy resin and flame retardant epoxy resin of reactive flame retardant

A reactive flame retardant and epoxy resin technology, applied in the field of materials, can solve the problems of reducing the transparency and refractive index of epoxy resin, deterioration of material physical and mechanical properties, and reducing the mechanical properties of resin matrix, so as to improve light extraction Efficiency, good physical and mechanical properties, and the effect of reducing the risk of fire accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of epoxy resin composition, it comprises epoxy resin E55, m-xylylenediamine and DOPO-AM, the weight percent of above-mentioned three is: 82%, 13%, 5%; Above-mentioned substance obtains cured product through curing reaction , the specific formula and performance test results are shown in Table 1.

Embodiment 2

[0046] An epoxy resin composition, which includes epoxy resin E55, m-xylylenediamine and DOPO-AM, the weight percentages of the above three are: 80%, 10%, and 10%; the above-mentioned substances are cured by curing reaction , the specific formula and performance test results are shown in Table 1.

Embodiment 3

[0050] An epoxy resin composition, which includes epoxy resin E55, m-xylylenediamine and DOPO-AM, the weight percentages of the above three are: 75%, 10%, and 15%; the above-mentioned substances are cured by curing reaction , the specific formula and performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com