Phosphazene compound, composite containing phosphazene compound, flame retardant containing composite and application

A compound, phosphazene technology, applied in the field of flame retardant compounds, can solve problems such as lack of exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0218] Embodiment 1. (about polychlorophosphazene, formula 3)

[0219] This example involves the compound The preparation and characterization of its crystalline form and performance-related studies.

[0220] In the scheme that the present invention implements, get each component raw material by phosphorus pentachloride: ammonium chloride: the mol ratio of catalyst=1: 1.1: 0.1, use organic solvent 1 2400~2600 grams per mole of phosphorus pentachloride Proportionally take organic solvent I; add phosphorus pentachloride and organic solvent I to reactor A under nitrogen protection, heat up to 80°C and stir at this temperature for 1 to 2 hours until phosphorus pentachloride is completely dissolved; Add ammonium chloride, catalyst and organic solvent I to reactor B under protection, start stirring, raise the temperature to reflux, slowly add the solution in reactor A to reactor B dropwise under reflux, after the dropwise addition Continue to stir under reflux for 1 to 2 hours; c...

Embodiment 2

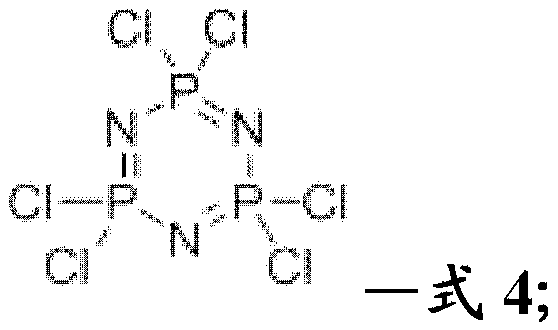

[0226] Embodiment 2. (about hexachlorocyclotriphosphazene, formula 4)

[0227] This embodiment also relates to the preparation and synthesis of chlorophosphazene, mainly relating to the synthesis, crystal form and properties of hexachlorocyclotriphosphazene. In the present embodiment, get each component raw material by phosphorus pentachloride: ammonium chloride: composite catalyst (pyridine and catalyzer)=1: 1.1: 0.06 molar ratio, use organic solvent I 2400 by every mole of phosphorus pentachloride Take the organic solvent I at a ratio of ~2600 grams; add phosphorus pentachloride and organic solvent I to the reactor A under nitrogen protection, heat up to 80°C and stir at this temperature for 1 to 2 hours until the phosphorus pentachloride is completely Dissolving; Add ammonium chloride, compound catalyst (pyridine and divalent metal chloride) and organic solvent I into reactor B under nitrogen protection, start stirring, heat up to reflux, and slowly put reactor A under refl...

Embodiment 3

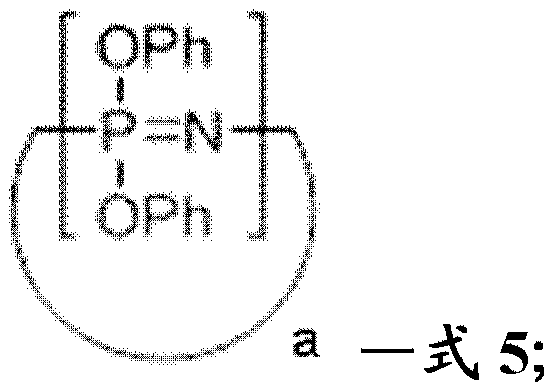

[0241] Embodiment 3 (phenoxyphosphazene compound, formula 5)

[0242] This embodiment involves the preparation of phenoxyphosphazene compounds, the characterization and research of crystal forms, and the testing of flame retardancy.

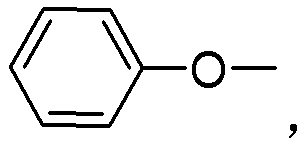

[0243] In this embodiment, the chlorophosphazene synthesized in the above examples can be used as one of the starting materials. Get each component raw material by the mol ratio of chlorophosphazene (from the preparation product of embodiment 1): phenol: acid-binding agent=1: 6.1: 12.2, by every 1 gram of formula chlorophosphazene with organic solvent III5~6 grams Proportionally take the organic solvent; under the protection of nitrogen, add chlorophosphazene, acid-binding agent and organic solvent III to reactor A, slowly add phenol dropwise to reactor A at a temperature lower than 40°C, and then raise the temperature to reflux Stir at reflux temperature for 3 to 5 hours; cool to room temperature, filter, wash the mother liquor with water, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com