Low-fiber-emergence low-warping high-tenacity flame-retardant PET/PETG composite material and preparation method

A composite material and low warpage technology, which is applied in the field of low floating fiber, low warpage and high toughness flame retardant PET/PETG composite materials, can solve the problems of poor surface effect, cold crystallization, slow nucleation speed, etc., and achieve surface performance and Improved impact properties, lower crystallization temperature and crystallization rate, improved orientation and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

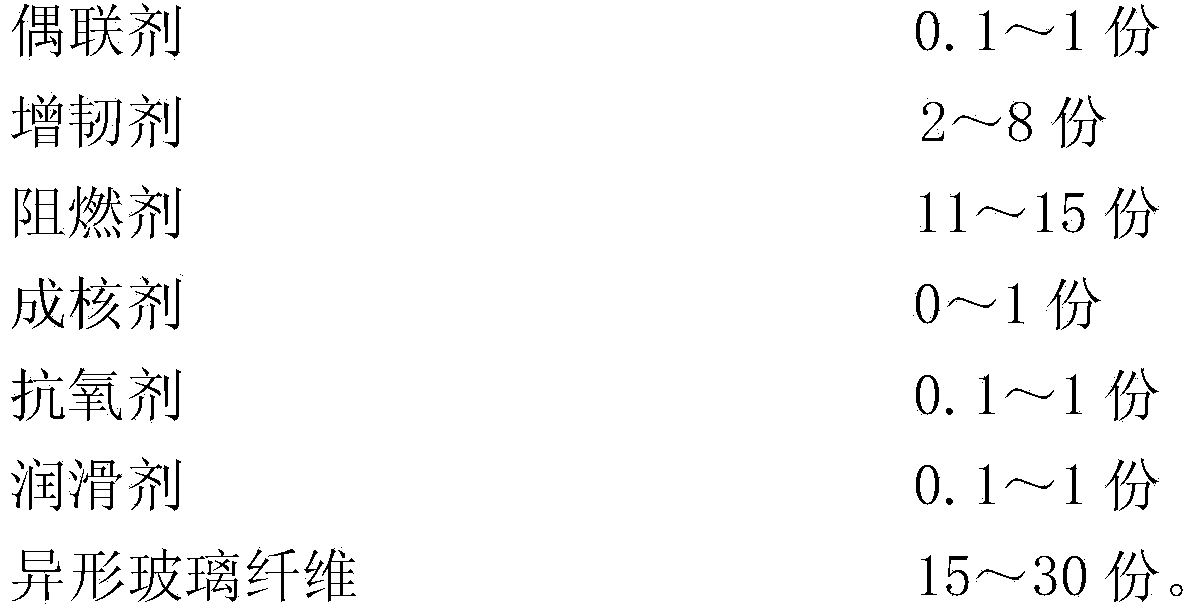

Method used

Image

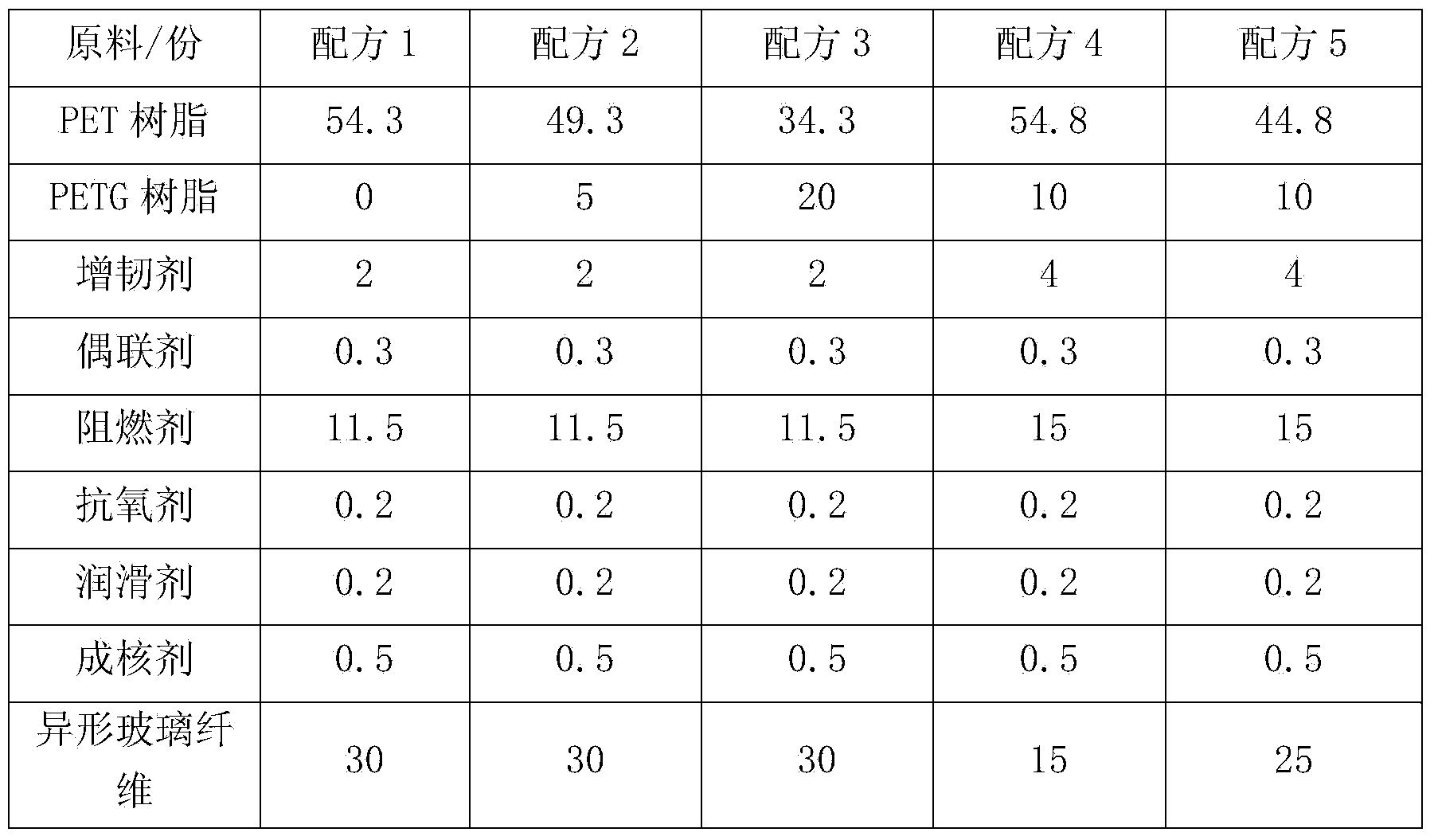

Examples

Embodiment 1

[0019] Mix 30 parts of PET resin, 5 parts of PETG resin, 0.1 part of coupling agent, 2 parts of toughening agent, 11 parts of flame retardant, 0.5 part of nucleating agent, 0.1 part of antioxidant, 0.1 part of lubricant, and then mix the mixture in The screw speed of the twin-screw extruder is 300r / min, and the extrusion temperature is 200-270°C. During the extrusion process, 15 parts of special-shaped glass fibers are added to extrude and granulate to obtain a composite material.

[0020] The intrinsic viscosity of PET resin is 0.7; the intrinsic viscosity of PETG resin is 0.8; the coupling agent is γ-aminopropyltriethoxysilane; the toughening agent is ethylene-methyl acrylate-glycidyl methacrylate terpolymer The flame retardant is a mixture of brominated epoxy resin and sodium antimonate in a ratio of 1:3; the nucleating agent is a mixture of sodium carboxylate and talc in a ratio of 1:1; the antioxidant is β(3 , 5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate an...

Embodiment 2

[0022] Mix 40 parts of PET resin, 15 parts of PETG resin, 0.5 parts of coupling agent, 5 parts of toughening agent, 13 parts of flame retardant, 0.5 part of nucleating agent, 0.5 part of antioxidant, 0.5 part of lubricant, and then mix the mixture in The screw speed of the twin-screw extruder is 300r / min, and the extrusion temperature is 200-270°C. During the extrusion process, 20 parts of special-shaped glass fibers are added to extrude and granulate to obtain a composite material.

[0023] The intrinsic viscosity of PET resin is 0.8; the intrinsic viscosity of PETG resin is 0.9; the coupling agent is γ-aminopropyltriethoxysilane; the toughening agent is ethylene-methyl acrylate-glycidyl methacrylate terpolymer The flame retardant is a mixture of brominated epoxy resin and sodium antimonate in a ratio of 1:4; the nucleating agent is a mixture of sodium carboxylate and talcum powder in a ratio of 1:2; the antioxidant is β(3 , 5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol pr...

Embodiment 3

[0025] Mix 50 parts of PET resin, 20 parts of PETG resin, 1 part of coupling agent, 8 parts of toughening agent, 15 parts of flame retardant, 1 part of nucleating agent, 1 part of antioxidant, 1 part of lubricant, and then mix the mixture in The screw speed of the twin-screw extruder is 300r / min, and the extrusion temperature is 200-270°C. During the extrusion process, 30 parts of special-shaped glass fibers are added to extrude and granulate to obtain a composite material.

[0026] The intrinsic viscosity of PET resin is 0.8; the intrinsic viscosity of PETG resin is 1.0; the coupling agent is γ-aminopropyltriethoxysilane; the toughening agent is ethylene-methyl acrylate-glycidyl methacrylate terpolymer The flame retardant is a mixture of brominated epoxy resin and sodium antimonate in a ratio of 1:5; the nucleating agent is a mixture of sodium carboxylate and talcum powder in a ratio of 1:4; the antioxidant is β(3 , 5-di-tert-butyl-4-hydroxyphenyl) pentaerythritol propionate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com