Flame retardant ABS master batch and preparation method thereof

A masterbatch, flame retardant technology, applied in the polymer field, can solve problems such as limited application, and achieve the effect of simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of flame-retardant ABS masterbatch, is characterized in that, comprises the following steps:

[0022] a: Weigh the carrier resin and flame retardant according to the ratio of parts by mass, and mix them evenly;

[0023] B: take by weighing zinc stearate and the mixture in a according to the proportioning of parts by mass, and mix uniformly;

[0024] c: Put the mixed raw materials in b into the hopper of the twin-screw extruder, melt and extrude, and granulate to obtain the flame-retardant masterbatch; the processing technology is as follows: the temperature in the first zone of the twin-screw extruder is 200-210°C, The temperature in the second zone is 220-240℃, the temperature in the third zone is 220-240℃, the temperature in the fourth zone is 220-240℃, the temperature in the fifth zone is 220-240℃, the temperature in the sixth zone is 220-240℃, the temperature in the seventh zone is 220-240℃, and the temperature in the eighth zone 220-240°C, the...

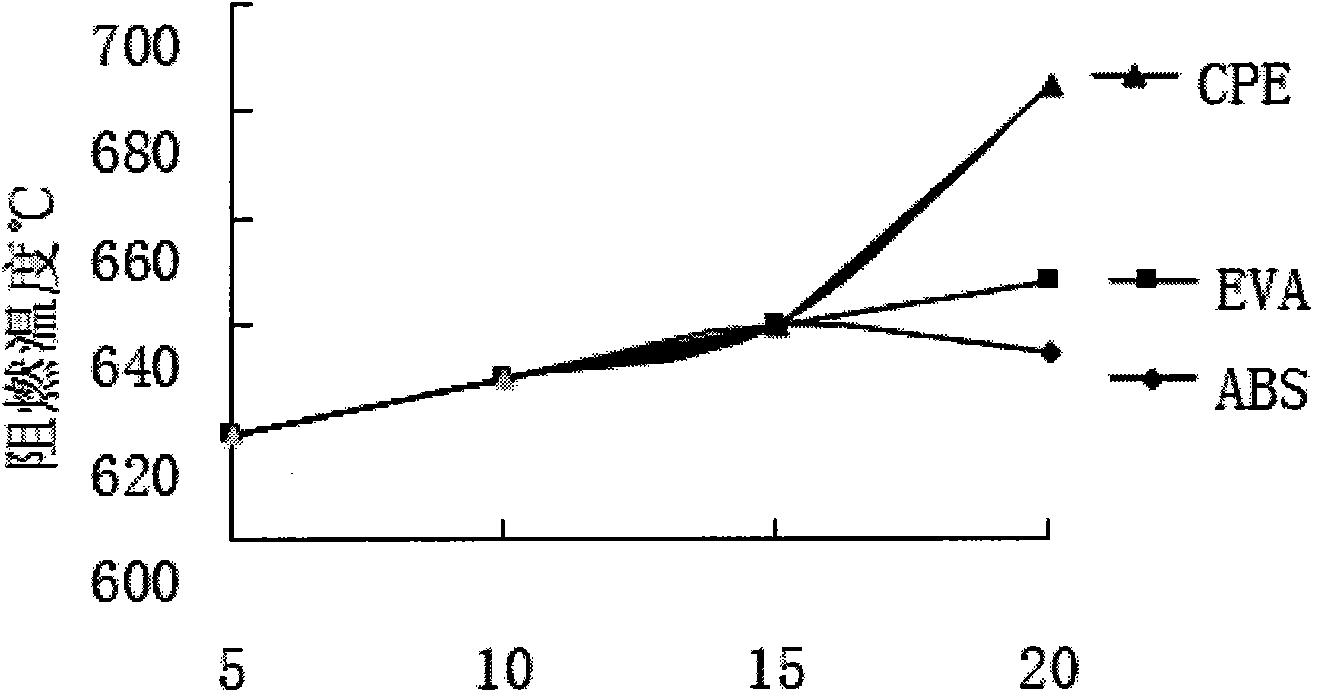

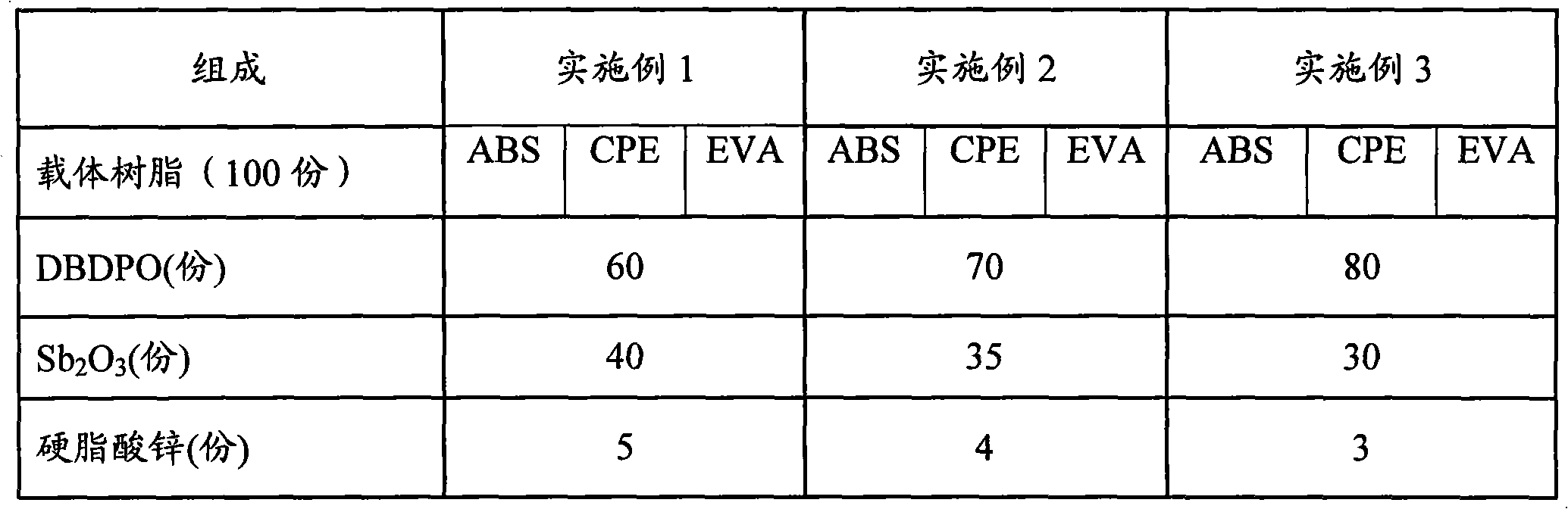

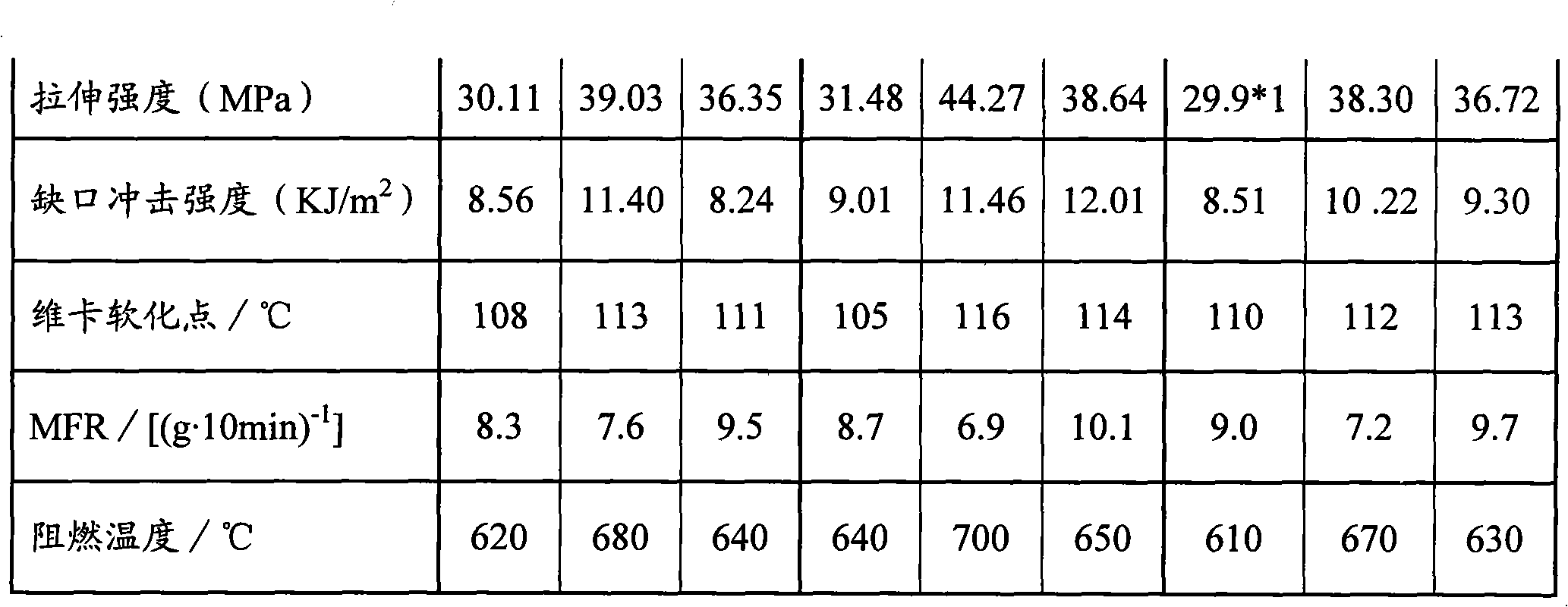

Embodiment 1

[0027] Three kinds of carrier resins are respectively 100 parts by mass parts, DBDPO60 parts, Sb 2 o 3 40 parts, 5 parts of zinc stearate, mixed at high and low speed for 3-5 MIN. Afterwards, the mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the processing temperature settings of each zone of the screw are: the temperature of the first zone is 200-210°C, the temperature of the second zone is 220-240°C, the temperature of the third zone is 220-240°C, the temperature of the fourth zone is 220-240°C, the temperature of the fifth zone is 220-240°C, The temperature of the sixth zone is 220-240°C, the temperature of the seventh zone is 220-240°C, the temperature of the eighth zone is 220-240°C, the temperature of the die head is 200-220°C, the residence time is 1-2min, and the pressure is 10-16MPa.

Embodiment 2

[0029] Three kinds of carrier resins are respectively 100 parts by mass parts, DBDPO70 parts, Sb 2 o 3 35 parts, 4 parts of zinc stearate, mixed at high and low speed for 3-5min. Afterwards, the mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the processing temperature settings of each zone of the screw are: the temperature of the first zone is 200-210°C, the temperature of the second zone is 220-140°C, the temperature of the third zone is 220-240°C, the temperature of the fourth zone is 220-240°C, the temperature of the fifth zone is 220-240°C, The temperature of the sixth zone is 220-240°C, the temperature of the seventh zone is 220-240°C, the temperature of the eighth zone is 220-240°C, the temperature of the die head is 200-220°C, the residence time is 1-2min, and the pressure is 10-16MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com