A kind of hydrophilic antibacterial non-woven non-woven fabric and preparation method thereof

A non-woven fabric and non-woven technology, which is applied in the field of hydrophilic antibacterial non-woven non-woven fabric and its preparation, can solve the problems of complex composition and performance impact of non-woven fabric, and achieve simple treatment process, increase hydrophilic performance, The effect of increased hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of hydrophilic antibacterial non-woven non-woven fabric, comprising polypropylene anti-sticking non-woven substrate and water-based antibacterial layer, water-based antibacterial layer includes the following raw materials in parts by weight: 0.5% sodium alginate, 3% chitosan, biological dye - Methylene blue 1%, phthalocyanine photosensitizer 0.1%, n-butanol 0.5%, sodium octanoate 0.5%, DMSO 20%, metal ion complexing agent EDTA 0.1%, benzalkonium bromide dimethyl benzyl ammonium bromide 0.1% and purified water 55%.

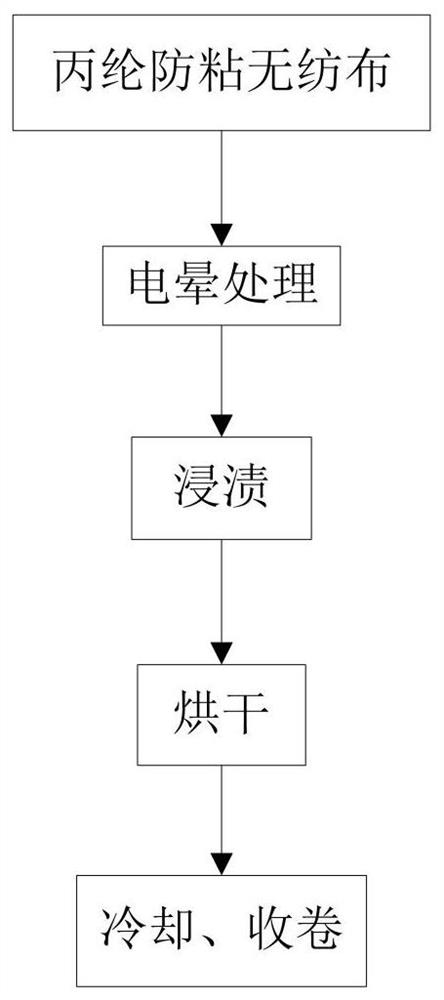

[0018] Such as figure 1 Shown, a kind of preparation method of hydrophilic antibacterial nonwoven nonwoven fabric, comprises the following steps:

[0019] (1) Place the polypropylene anti-adhesive non-woven fabric substrate on the roller, and the non-woven fabric travels at a speed of 5m / min. Corona treatment is performed on the surface of the polypropylene anti-adhesive non-woven fabric substrate by a corona machine. The treatment adopts an incline...

Embodiment 2

[0023] A kind of hydrophilic antibacterial non-woven non-woven fabric, comprising polypropylene anti-sticking non-woven substrate and water-based antibacterial layer, water-based antibacterial layer includes the following raw materials in parts by weight: sodium alginate 1%, chitosan 4%, biological dye - Methylene blue 2%, phthalocyanine photosensitizer 1%, n-butanol 1%, sodium octanoate 1%, DMSO 22%, metal ion complexing agent EDTA 0.2%, benzalkonium bromide dimethyl benzyl ammonium bromide 1% and purified water 60%.

[0024] Such as figure 1 Shown, a kind of preparation method of hydrophilic antibacterial nonwoven nonwoven fabric, comprises the following steps:

[0025] (1) Place the polypropylene anti-adhesive non-woven fabric substrate on the roller, and the non-woven fabric travels at a speed of 5m / min. Corona treatment is performed on the surface of the polypropylene anti-adhesive non-woven fabric substrate by a corona machine. The treatment adopts an inclined discharg...

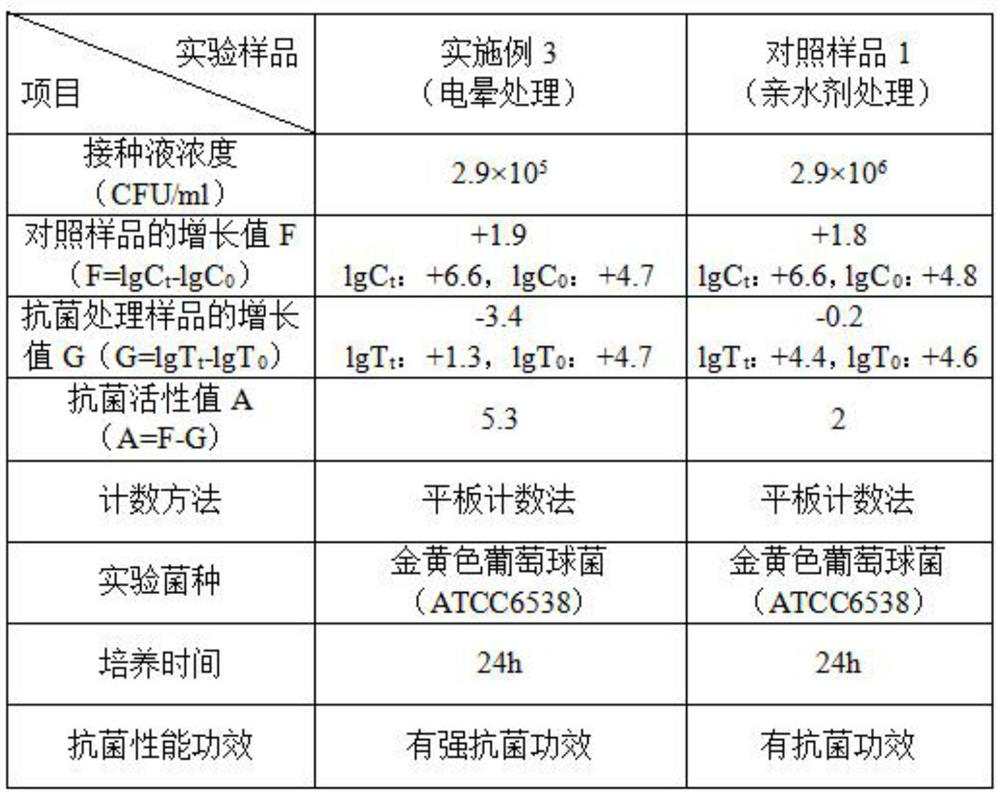

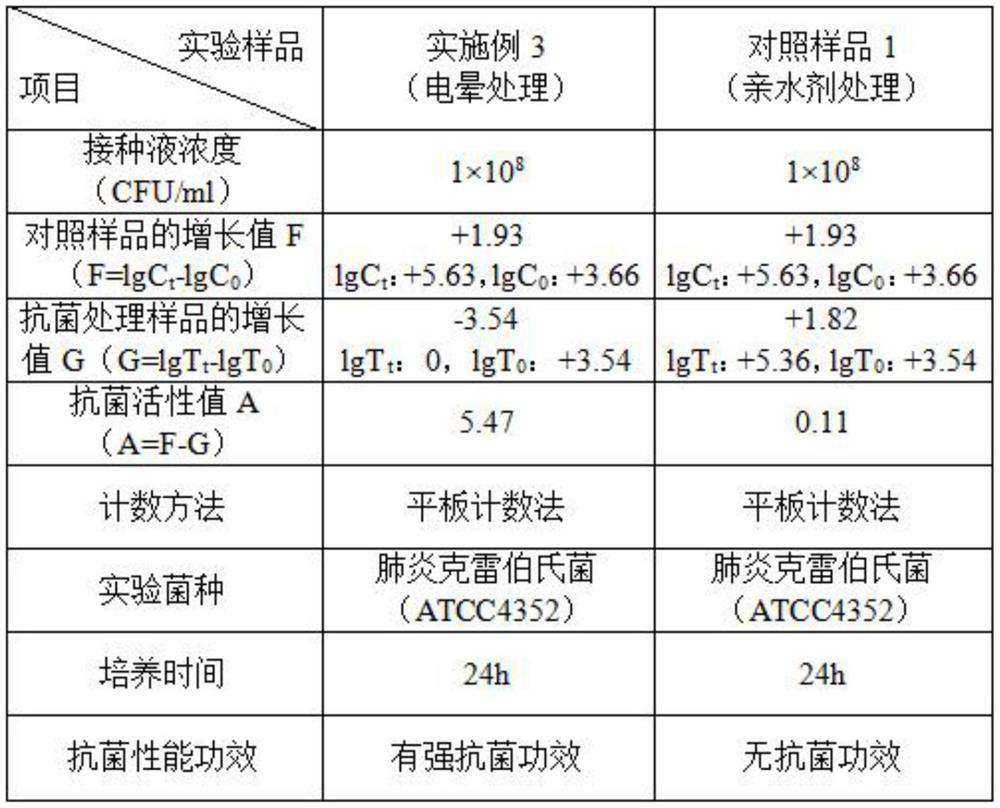

Embodiment 3

[0029] A kind of hydrophilic antibacterial non-woven non-woven fabric, comprising polypropylene anti-sticking non-woven base material and water-based antibacterial layer, the water-based antibacterial layer includes the following raw materials in parts by weight: sodium alginate 2%, chitosan 3%, biological dye - Methylene blue 4%, phthalocyanine photosensitizer 2%, n-butanol 1.2%, sodium octanoate 2%, DMSO 20%, metal ion complexing agent EDTA 0.3%, benzalkonium bromide dimethyl benzyl ammonium bromide 4% and purified water 70%.

[0030] Such as figure 1 Shown, a kind of preparation method of hydrophilic antibacterial nonwoven nonwoven fabric, comprises the following steps:

[0031] (1) Place the polypropylene anti-adhesive non-woven fabric substrate on the roller, and the non-woven fabric travels at a speed of 5m / min. Corona treatment is performed on the surface of the polypropylene anti-adhesive non-woven fabric substrate by a corona machine. The treatment adopts an incline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com