Application of hyperbranched dyeing assistant to increasing of dyeability of superfine-fiber polyurethane synthetic leather

A technology of hyperbranched polymers and dyeing auxiliaries, which is applied in the fields of dyeing, textiles and papermaking, to achieve the effects of improving uneven dyeing, good market development prospects, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

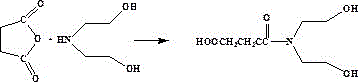

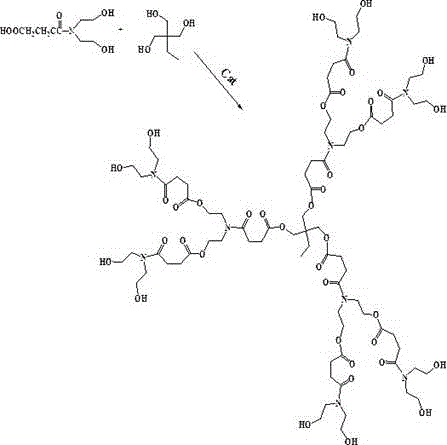

[0032] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Slowly add it dropwise into the three-necked bottle containing diethanolamine, stir while adding dropwise, drop it in 1h-1.5h, then react at room temperature for 3h-5h, and the reaction product is AB 2 type monomer. In the above system, add 180mL toluene (toluene is a water-carrying agent), then add 20.126g (0.15mol) trimethylolpropane as a nuclear molecule, and add 0.500g p-toluenesulfonic acid as a catalyst; then start heating until boiling, There is reflux in the spherical condenser. The heat preservation reaction is carried out for 7h-8h to obtain a hyperbranched polymer solution with a hydroxyl group at the end.

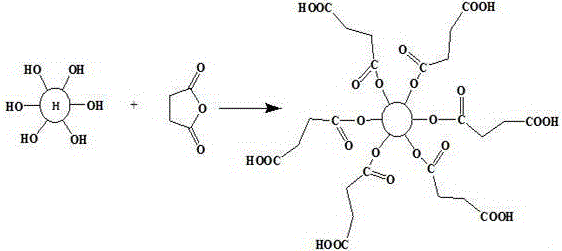

[0033] (2) Weigh 90.063g (0.90mol) of succinic anhydride and 0.500g of p-toluenesulfonic acid, first add p-toluene...

Embodiment approach 2

[0036] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Slowly add it dropwise into the three-necked bottle containing diethanolamine, stir while adding dropwise, drop it in 1h-1.5h, then react at room temperature for 3h-5h, and the reaction product is AB 2 type monomer. Add 180mL of toluene to the above system first (toluene is a water-carrying agent), then add 6.709g (0.05mol) trimethylolpropane as a nuclear molecule, and add 0.500g of p-toluenesulfonic acid as a catalyst; then start heating until boiling, There is reflux in the spherical condenser. The heat preservation reaction is carried out for 7h-8h to obtain a hyperbranched polymer solution with a hydroxyl group at the end.

[0037] (2) Weigh 60.042g (0.60mol) of succinic anhydride and 0.5g of p-toluenesulfonic acid, first add p...

Embodiment approach 3

[0040] (1) Weigh 45.032g (0.45mol) of succinic anhydride and 47.313g (0.45mol) of diethanolamine, first add diethanolamine into a three-necked flask with a magnetic stirrer, then dissolve succinic anhydride with an appropriate amount of DMAc; then Slowly add it dropwise into the three-necked bottle containing diethanolamine, stir while adding dropwise, drop it in 1h-1.5h, then react at room temperature for 3h-5h, and the reaction product is AB 2 type monomer. In the above system, add 180mL toluene (toluene is a water carrier), then add 2.952g (0.022mol) trimethylolpropane as a nuclear molecule, add 0.500g p-toluenesulfonic acid as a catalyst; then start heating until boiling, There is reflux in the spherical condenser. The heat preservation reaction is carried out for 7h-8h to obtain a hyperbranched polymer solution with a hydroxyl group at the end.

[0041] (2) Weigh 53.037g (0.53mol) of succinic anhydride and 0.5g of p-toluenesulfonic acid, first add p-toluenesulfonic acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com