The method of sic/graphene oxide composite modified epoxy resin

A graphene composite and epoxy resin technology, applied in the field of composite materials, can solve problems such as poor thermal conductivity, complicated preparation process, and great influence on material properties, and achieve the effects of improving mechanical properties, avoiding agglomeration, and improving bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

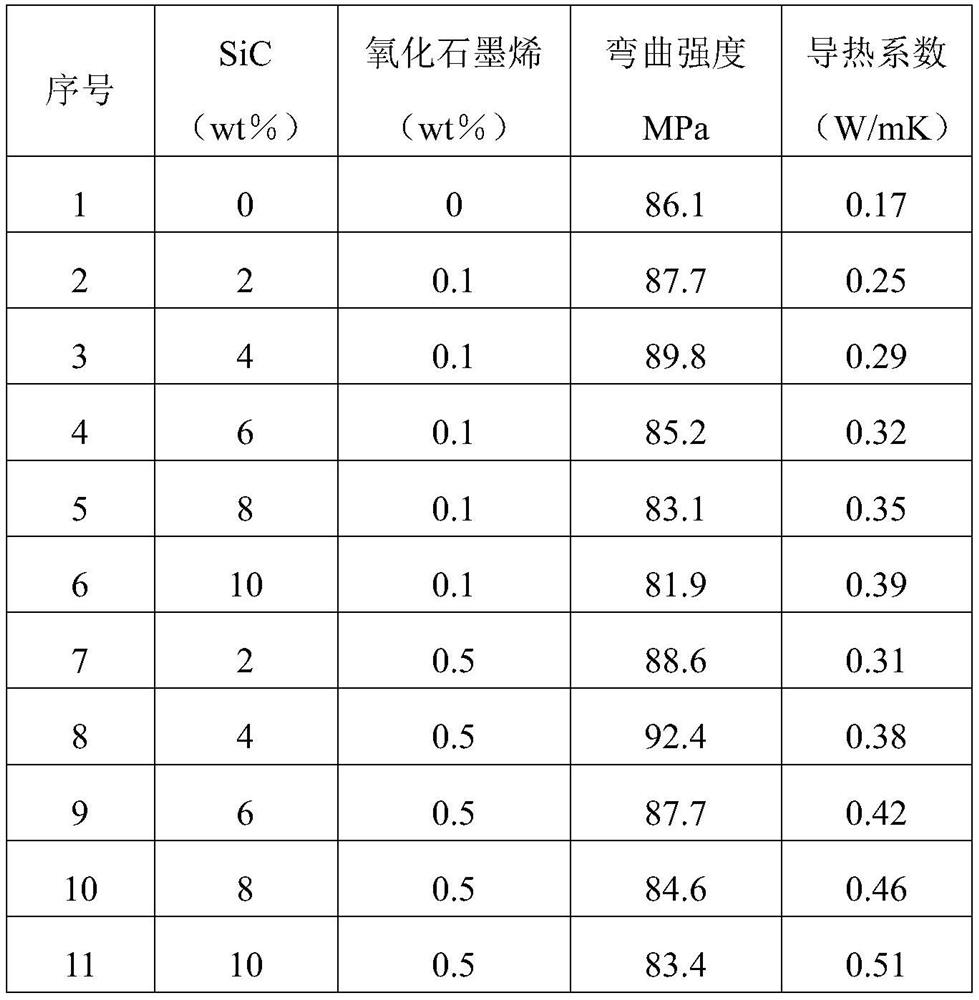

Examples

Embodiment 1

[0025] 1) Preparation of graphene oxide / SiC epoxy diluent

[0026] Put 5g of nano-SiC (6.25%, mass ratio to epoxy resin, the same below) powder in a hydrochloric acid solution with a mass fraction of 5%, stir for 2 hours, and wash with a sufficient amount of deionized water after solid-liquid separation. Take a certain amount of graphite oxide slurry prepared by the Hummers method, and ultrasonically disperse it in deionized water to obtain a graphene oxide aqueous dispersion with a concentration of 1 mg / mL. The treated SiC powder was dispersed in 100 mL of graphene oxide (0.125%) aqueous dispersion, and then 2 mL of aminosilane coupling agent (KH550) was added, and heated to 80° C. for 4 h. Add 4g (5%) butyl glycidyl ether to the system again, remove the water in the system by distillation under reduced pressure, then carry out ultrasonic treatment, obtain the graphene oxide / SiC epoxy diluent that filler is evenly dispersed;

[0027] 2) Preparation of graphene oxide / SiC epox...

Embodiment 2

[0030] 1) Preparation of graphene oxide / SiC epoxy diluent

[0031] 10g (10%) nano-SiC powder was placed in a hydrochloric acid solution with a mass fraction of 5%, stirred for 2 hours, and washed with a sufficient amount of deionized water after solid-liquid separation. Take a certain amount of graphite oxide slurry prepared by the Hummers method, and ultrasonically disperse it in deionized water to obtain a graphene oxide aqueous dispersion with a concentration of 1.5 mg / mL. The treated SiC powder was dispersed in 100 mL of graphene oxide water (0.15%) dispersion, 3 ml of aminosilane coupling agent (KH550) was added to the system, and heated to 90° C. for 4 h. Add 15g (15%) ethylene glycol glycidyl ether to the system again, remove the water in the system by distillation under reduced pressure, then carry out ultrasonic treatment, obtain the graphene oxide / SiC epoxy diluent that filler is evenly dispersed;

[0032] 2) Preparation of graphene oxide / SiC epoxy resin composites ...

Embodiment 3

[0035] 1) Preparation of graphene oxide / SiC epoxy diluent

[0036]6g (5%) nano-SiC powder was placed in a hydrochloric acid solution with a mass fraction of 5%, stirred for 2 hours, and washed with a sufficient amount of deionized water after solid-liquid separation. Take a certain amount of graphite oxide slurry prepared by the Hummers method, and ultrasonically disperse it in deionized water to obtain a graphene oxide aqueous dispersion with a concentration of 1.5 mg / mL. The treated SiC powder was dispersed in 100 mL of graphene oxide water (0.125%) dispersion, then 2 mL of aminosilane coupling agent (KH550) was added to the system, and heated to 100 ° C for 4 h. Add 12g (10%) ethylene glycol glycidyl ether to the system again, remove the water in the system by distillation under reduced pressure, then carry out ultrasonic treatment, obtain the graphene oxide / SiC epoxy diluent that filler is evenly dispersed;

[0037] 2) Preparation of graphene oxide / SiC epoxy resin composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com