High-specific-heat-capacity substance based electric welding protective plus material and preparation method thereof

A high specific heat capacity, fabric technology, applied in plant fibers, animal fibers, fibers repelling liquids, etc., can solve the problems of high price, poor resistance to electric welding spark shock, airtight, etc., to prevent long-term contact and isolation. Thermal other properties, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

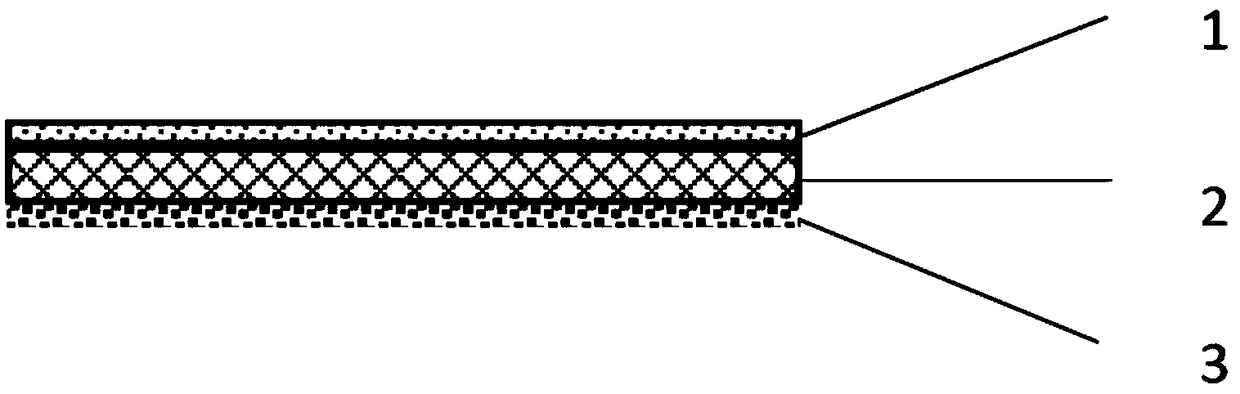

[0031] The pure cotton fabric finished by Proben is selected as the flame-retardant base fabric, and the front of the fabric is coated with 55g / m 2 The application amount applies a coating composition comprising the following components: 35 parts by weight of oily polyurethane, 2 parts by weight of polyester polyol crosslinking agent, 55 parts by weight of sodium polyacrylate powder with a particle size of 300-10000 mesh, 1 part by weight of Calcium stearate, 7 parts by weight of lignin powder with a particle size of 3000-10000 mesh, dried at 120°C for 9 minutes, heat-set at 160°C for 1 minute, and then applied fluorine-containing water-repellent in the form of mist droplets on the reverse side of the fabric. Oil agent WG-8900. Spray the super-absorbent coating on the front with liquid water at an application rate of 100g / m 2 , so that the surface of the fabric is in a wet state, and it has a water retention capacity of up to 4 hours under room temperature drying conditions. ...

Embodiment 2

[0034] The fabric made by blending 50% cotton fiber and 50% wool fiber by weight is then processed by the Prouben method to obtain a flame-resistant base cloth. 60g / m on the front of the fabric 2 The amount of application is to apply a coating composition comprising the following components: 45 parts by weight of oily polyurethane, 3 parts by weight of polyester polyol crosslinking agent, 45 parts by weight of hydroxypropyl methylcellulose powder with a particle size of 300-10000 mesh, 2 parts by weight of calcium stearate, 5 parts by weight of lignin powder with a particle size of 3000-10000 meshes, dried at 120°C for 5 minutes, heat-set at 160°C for 3 minutes, and then applied fluorine-free Waterproof and water repellent finishing agent NFC. Spray the super-absorbent coating on the front with liquid water at an application rate of 200g / m 2 , so that the surface of the fabric is in a wet state, and it has a water retention capacity of up to 6 hours under room temperature dr...

Embodiment 3

[0037]A fabric made of 30.8% by weight of flame-retardant viscose, 35.6% by weight of acrylic and 33.6% by weight of flame-retardant vinylon blended at 45g / m on the front of the fabric 2 Apply the coating composition comprising the following components: 55 parts by weight of oily polyurethane, 2 parts by weight of polyester polyol crosslinking agent, 30 parts by weight of sodium alginate with a particle size of 300-10000 mesh, 4 parts by weight of hard Calcium fatty acid, 9 parts by weight of lignin powder with a particle size of 3000-10000 mesh, drying at 120°C for 3 minutes, heat setting at 160°C for 5 minutes, and then applying silicone water-repellent finishing agent WS in the form of screen printing on the back of the fabric 60CN. Spray the super-absorbent coating on the front with liquid water at an application rate of 300g / m 2 , so that the surface of the fabric is in a wet state, and it has a water retention capacity of up to 8 hours under room temperature drying cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com