Patents

Literature

60results about How to "Good water and chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special adhesive for underwater construction and preparation method thereof

InactiveCN103555243AIncrease elasticityGood resistance to cold and heat shockNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveActive agent

The invention discloses a special adhesive for underwater construction, and the special adhesive comprises an A component and a B component at a weight ratio of 100:(20-100):25, wherein the A component is prepared from the following raw materials in parts by weight: 30-60 parts of modified epoxy resin, 5-30 parts of tackifier, 2-10 parts of accelerant, 5-15 parts of reactive diluent, 0.1-0.3 parts of surfactant, and 10-35 parts of filler powder; the B component is prepared from the following raw materials in parts by weight: 0-60 parts of ketimine, 0-60 parts of phenalkamine, 30-65 parts of modified polyamide, 1-6 parts of curing accelerator, and 2-15 parts of moisture repellent. The special adhesive for underwater construction has the advantages of being good in bonding strength in water, good in toughness, water-resistant, capable of resisting chemical attack, strong in initial viscous force and convenient to construct, and great improvement is brought for the underwater construction field.

Owner:YANTAI DARBOND TECH

Hollow Silica Microparticles, Compositions for Forming Transparent Coating Film Containing the Same, and Substrate Having Transparent Coating Film

InactiveUS20090286070A1Excellent abrasion resistanceGood adhesivenessMaterial nanotechnologyPigmenting treatmentMicroparticleSilicon dioxide

Hollow silica microparticles suppress whitening of a transparent coating film and show excellent abrasion resistance and adhesiveness. The microparticles having the average particle diameter of 5 to 300 nm and the specific surface area of 50 to 1500 m2 / g, and also having an outer shell in which cavities are formed. The microparticles lose the weight by 1.0 W % or more at a temperature range from 200° C. to 500° C. when measured by the thermogravimetry (TG), and the microparticles have a positive DTA peak at the temperature range when measured by the differential thermogravimetric analysis (DTA).

Owner:JGC CATALYSTS & CHEM LTD

Thermosensitive recording material and method of production thereof

InactiveUS6890698B2Improve water resistanceShorten the timePhotosensitive materialsCoatingsLeuco dyeMethods of production

A thermosensitive recording material having a support, a thermosensitive coloring layer provided on the support and containing a leuco dye and a color developer for developing the leuco dye upon application of heat, and a protective layer provided on the thermosensitive coloring layer and containing polyvinyl alcohol having reactive carbonyl groups, a hydrazide compound which crosslinks the polyvinyl alcohol through the reactive carbonyl groups, and a basic filler. The protective layer may be formed by applying a coating composition containing polyvinyl alcohol having reactive carbonyl groups, a hydrazide compound which crosslinks the polyvinyl alcohol through the reactive carbonyl groups, and a basic filler onto a thermosensitive coloring layer provided on a support, and drying the applied coating composition to crosslink the polyvinyl alcohol.

Owner:RICOH KK

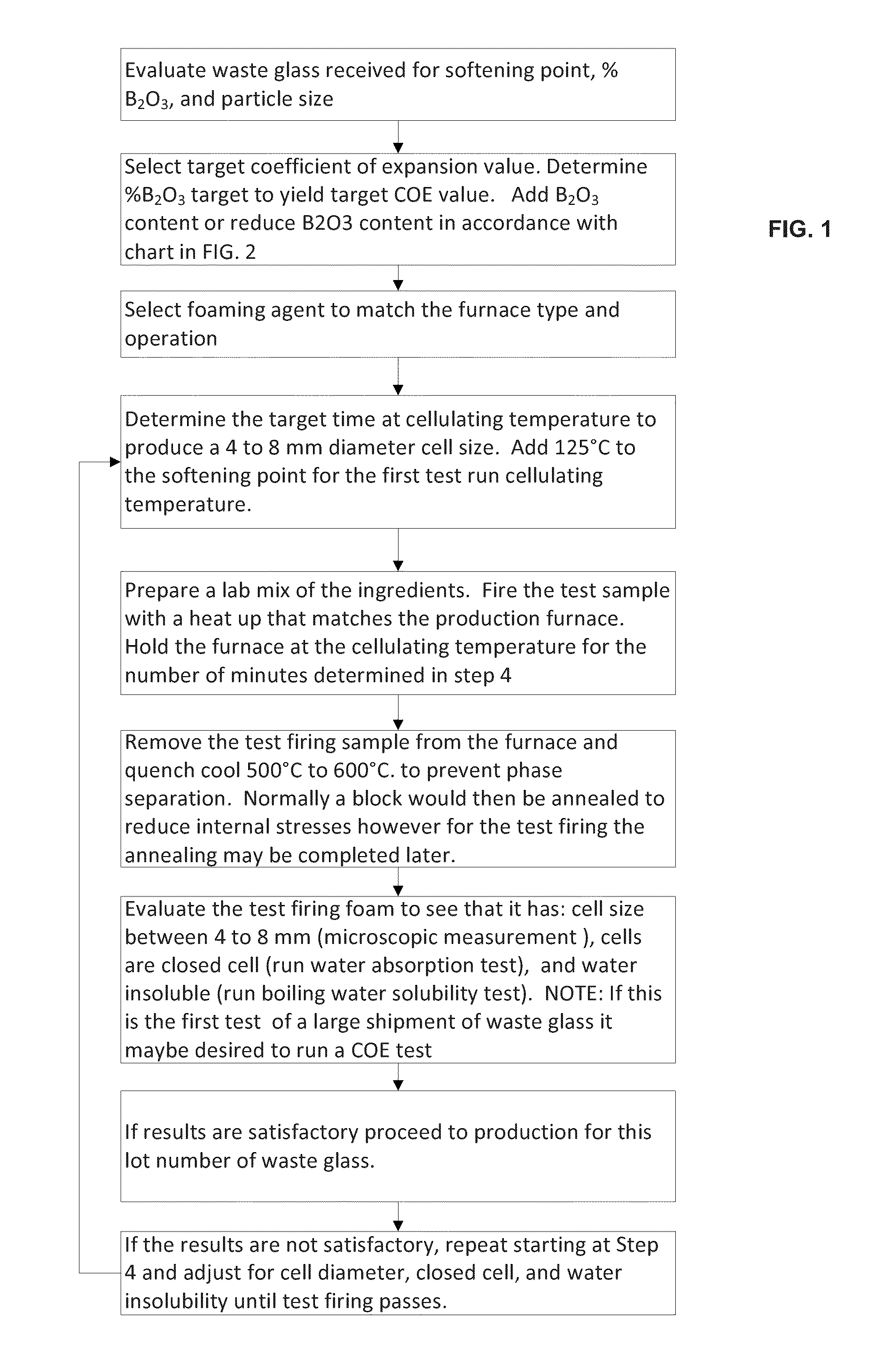

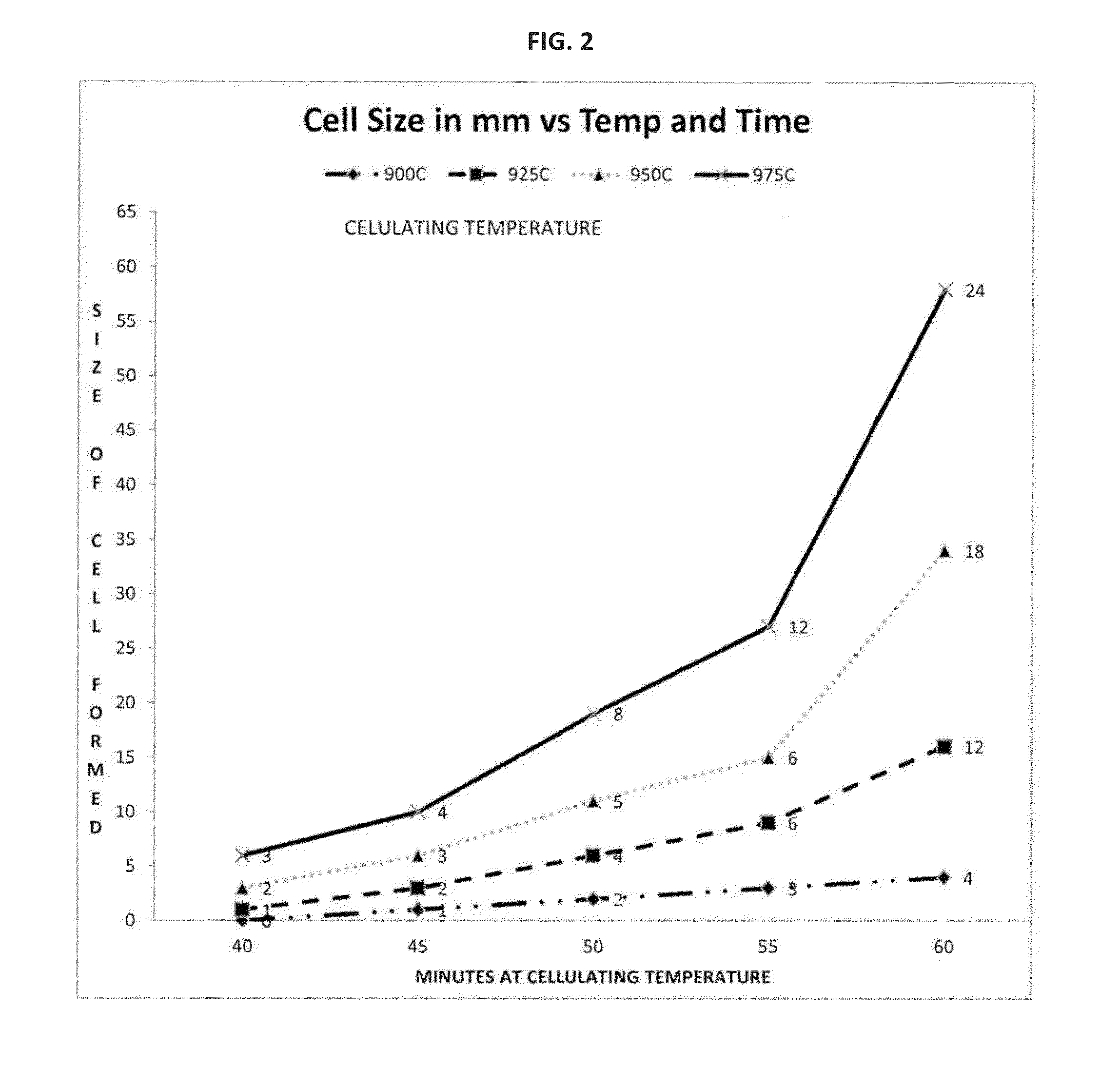

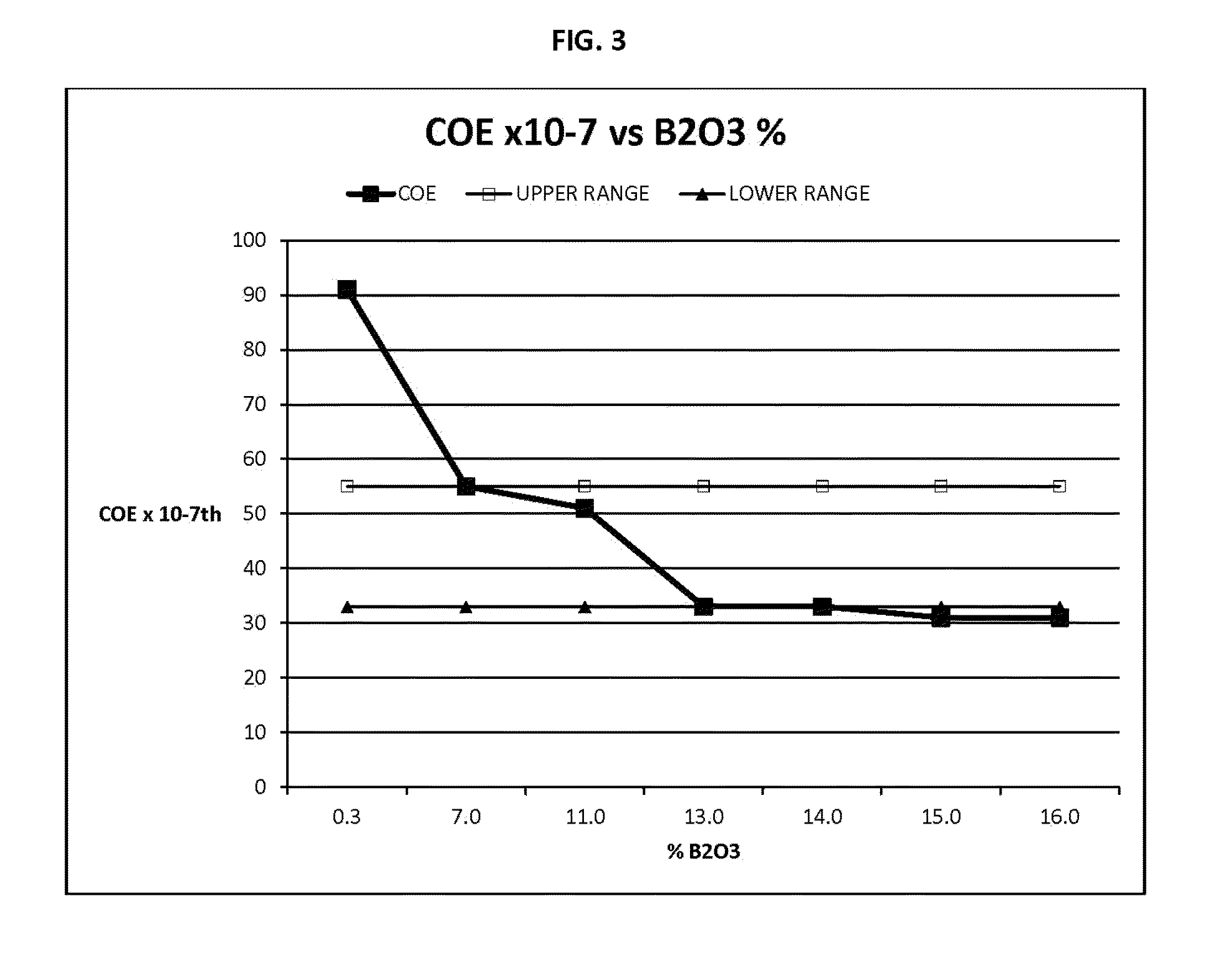

Method for producing cellular glass from waste glass streams

InactiveUS8991213B1Quality improvementLow costGlass shaping apparatusGlass productionFoaming agentWaste stream

A method by which recovered glass from waste steams can be used to create a closed cell foam glass in the 9 to 13 lbs / ft3 density range using a single-step foaming process. The waste glass is mixed with foaming agents and the boron content is adjusted and maintained between 7 to 14% of the mixture. The mixture is formed into a charge and fired at a temperatures ranging from 100° C. to 250° C. above the softening point of the waste glass for a controlled period of time. The waste glass can be obtained from commercial waste streams of high borosilicate glass to common container glass from recycling sources. The glass is ground to an appropriate size and mixed with fluxes, enhancers, and foaming agents which are then properly dispersed within the mixture. The mixture batch can be adjusted with respect to the additives, firing temperature and schedule to produce the desired closed-cell end product which is water insoluble, acid resistant and has a low coefficient of expansion within the range of 33×10−7 to 55×10−7.

Owner:HEMPEL AS

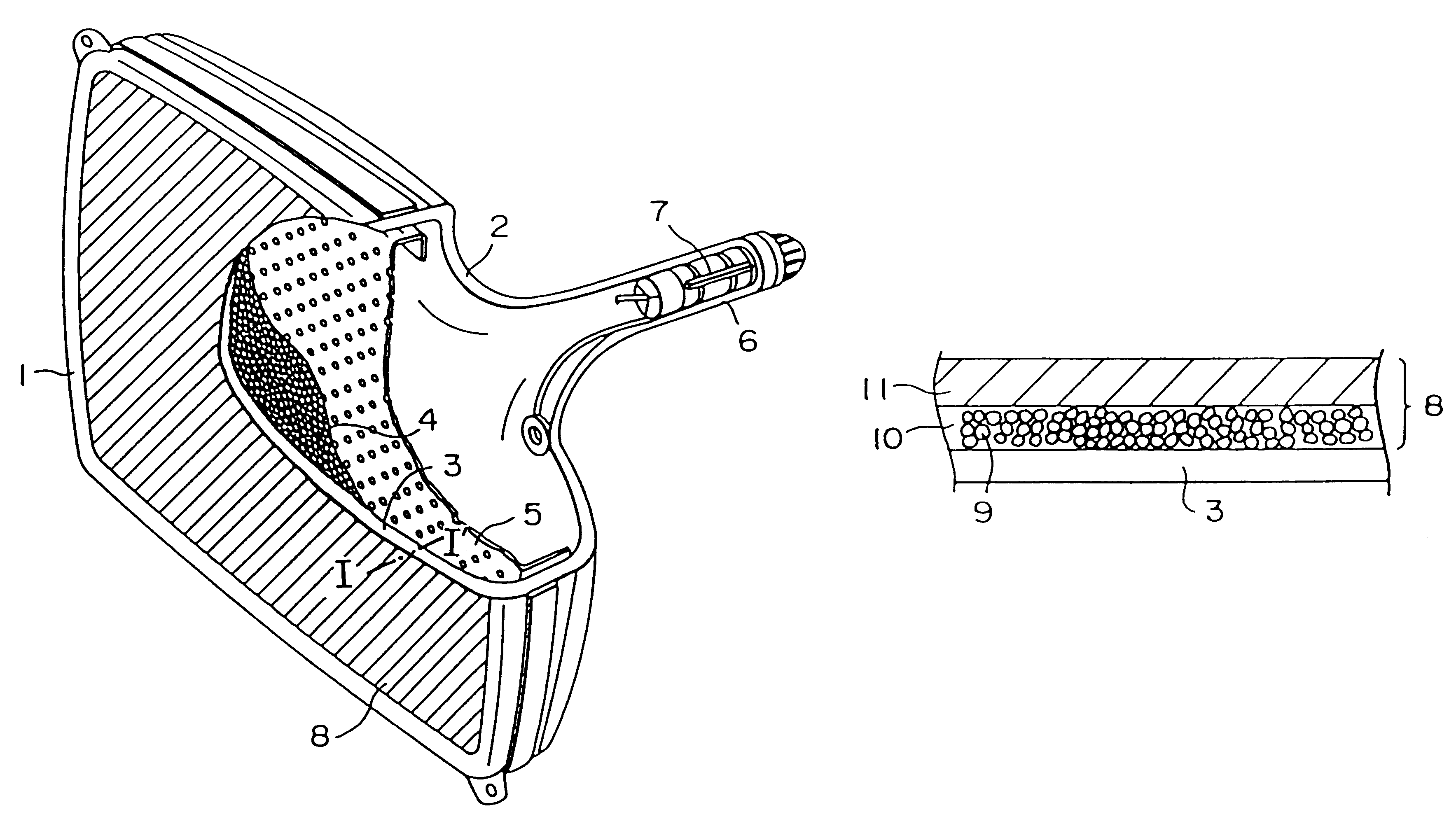

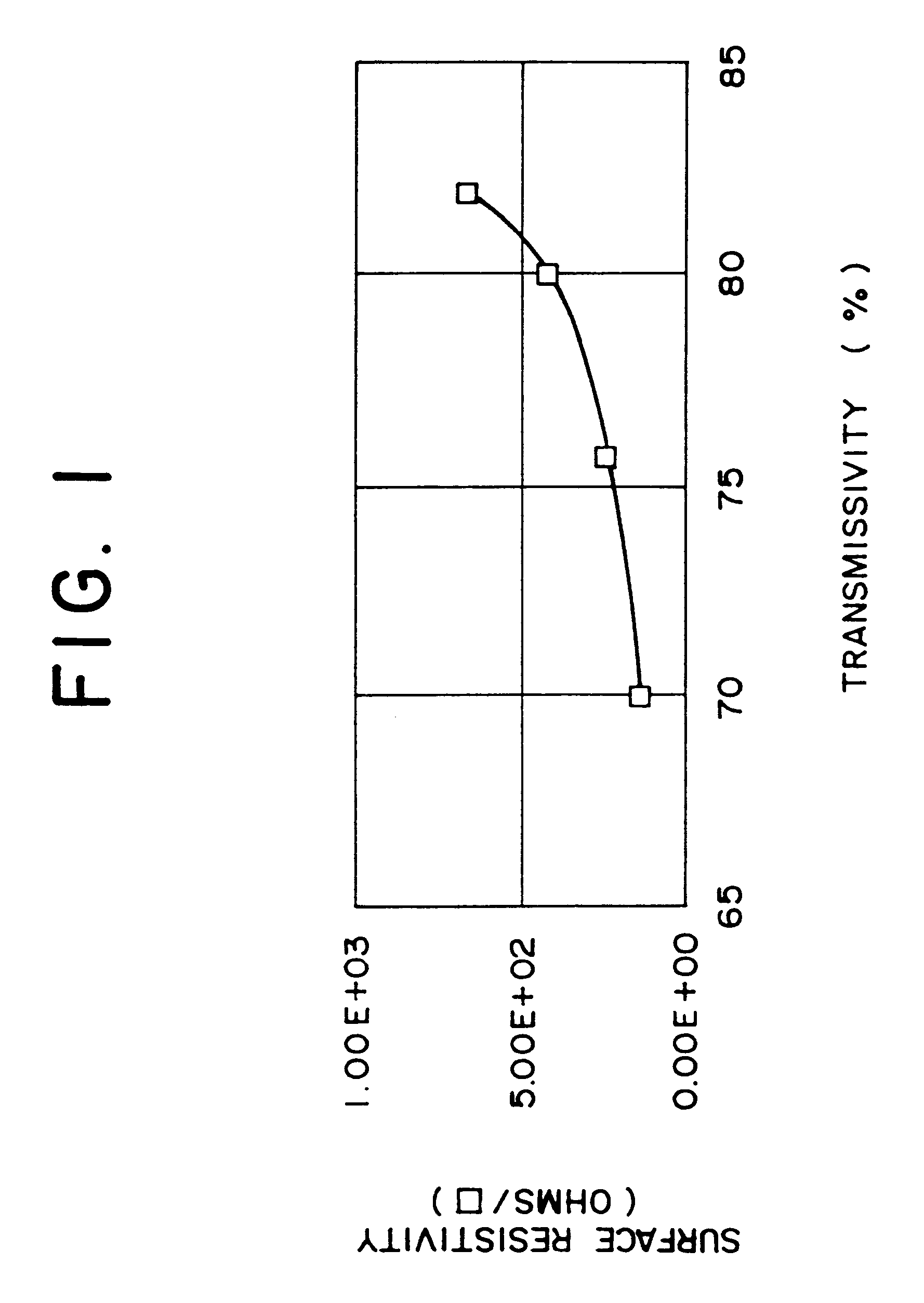

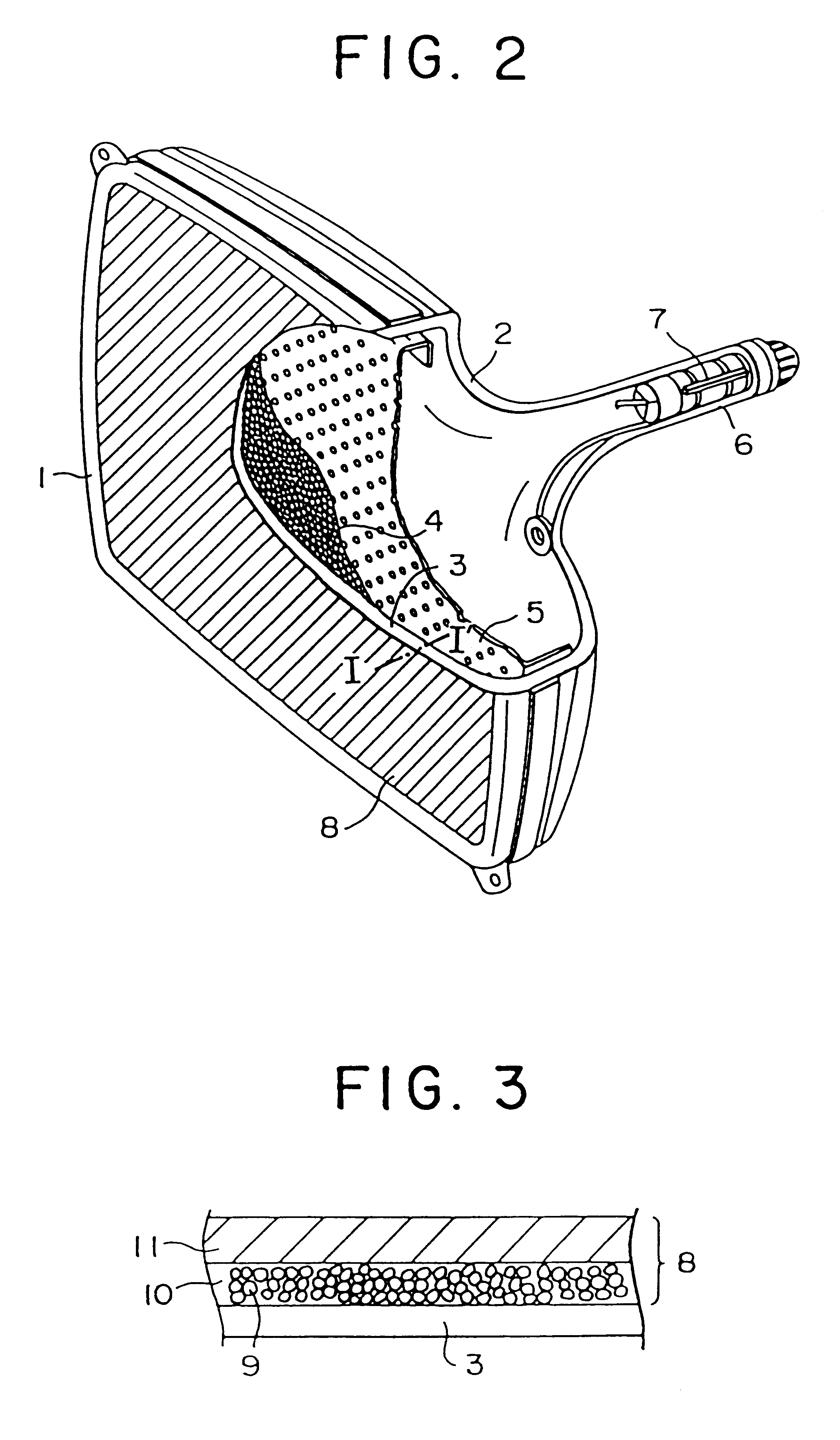

Method of fabricating conductive anti-reflection film for a cathode ray tube

InactiveUS6184125B1Good water and chemical resistanceSuppress lightTube/lamp screens manufactureCathode-ray/electron-beam tube vessels/containersOptoelectronicsCathode ray

A second coat film is formed on a first coat film containing a conductive substance, the second coat film having an expansion coefficient almost the same as the expansion coefficient of the first coat film under a sintering condition. The first and second coat films are sintered at the same time. Thus, a conductive anti-reflection film with sufficiently low surface resistance, excellent water resistance and chemical resistance, and reduced reflected light can be obtained. When the conductive anti-reflection film is used, a cathode ray tube that is almost free from the AEF (Alternating Electric Field) and that displays a high quality picture for a long time can be obtained.

Owner:KK TOSHIBA

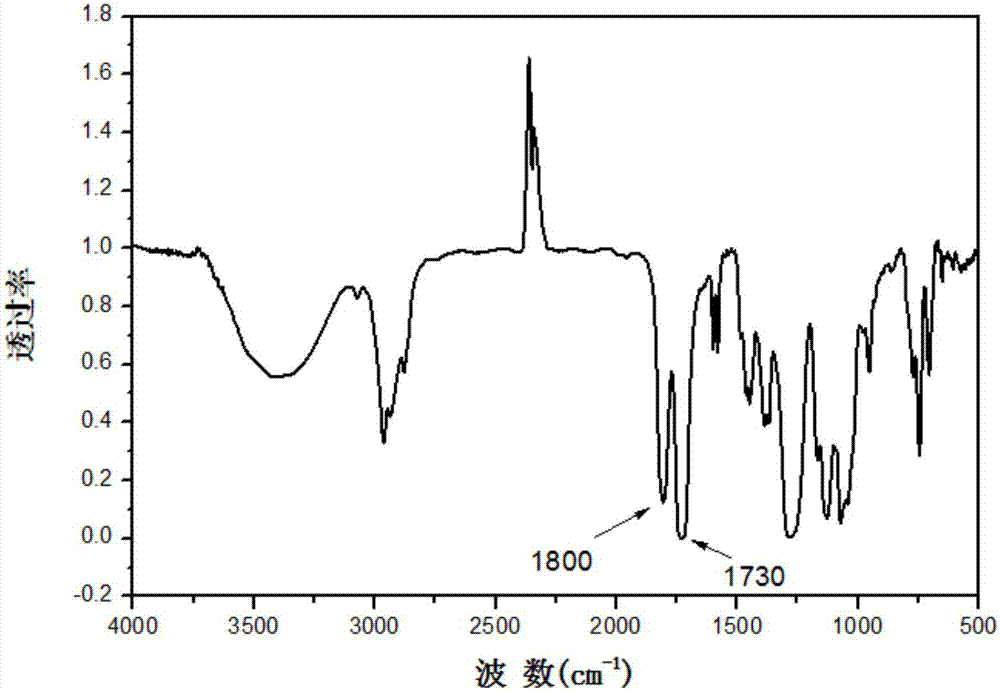

Polycyclic carbonate resin, preparation method thereof at normal pressure and application thereof

ActiveCN107189053AAvoid high temperature and pressureLow equipment requirementsPolyurea/polyurethane coatingsPolyolHydrogen

The invention discloses polycyclic carbonate resin, a preparation method thereof at normal pressure and application thereof. The preparation method includes: using anhydride, polyol and epichlorohydrin as raw materials to synthesize chlorohydrin resin; further enabling the chlorohydrin resin and hydrogen carbonate to synthesize the polycyclic carbonate resin in an atmosphere with a catalyst and CO2. High temperature and high pressure are not needed for preparation of the polycyclic carbonate resin, and reaction can be realized at the normal pressure, so that process and equipment are simple, reaction time is short, and the raw materials are easy to get. The polycyclic carbonate resin prepared by the method is low in volatility and basically nontoxic and has high biodegradability. Mechanical performance and chemical medium resistance of non-isocyanate polyurethane synthesized by the polycyclic carbonate resin and polyamine are improved greatly, and medium permeability resistance is lowered greatly; the synthesis process is unaffected by moisture, and the polycyclic carbonate resin is expected to become a good-performance environment-friendly material to replace conventional polyurethane.

Owner:SOUTH CHINA UNIV OF TECH +1

Fireproof building coating

InactiveCN105038463AGood gloss and color retentionEasy constructionFireproof paintsAnti-corrosive paintsSilicone resinWeather resistance

The invention provides a fireproof building coating. A main body of the fireproof coating adopts combination of thermoplastic acrylic resin, hydroxy acrylic resin and organic silicon resin, and due to the combination of the resin, the coating not only has the good light and color preserving property and the water and chemical resistance property, but also is convenient to construct, high in drying speed and economical in energy. According to the fireproof building coating, mullite fibers and silica fibers which can resist high temperature are added, and therefore not only can the mechanical strength of a coating layer be significantly improved, but also the weather resistance and corrosion resistance of the coating layer can be improved. When a fire disaster occurs, through the synergistic effect of all the components in the formula, the fire retardant effect is good, and smoke formation is little.

Owner:章俊

Preparation method of fireproof coating

ActiveCN105062291AGood gloss and color retentionGood water and chemical resistanceFireproof paintsWeather resistanceAcrylic resin

The invention provides a preparation method of a fireproof coating. The preparation method has the beneficial effects that thermoplastic acrylic resin, hydroxy acrylic resin and organic silicon resin are combined to be used as a main body of the fireproof coating; through combination of the three kinds of resin, the coating not only has good light and color retention properties and water and chemical resistance but also is convenient to construct, has high drying speed and saves energy; as high temperature resistant mullite and silica fibers are also added to the coating, not only can the mechanical strength of coats be obviously improved but also the weather and corrosion resistance of the coats can be improved; in case of a fire, through synergy of various components in the formula, the coating has good flame retardant effects and is less in fuming.

Owner:北京昊天防火材料厂

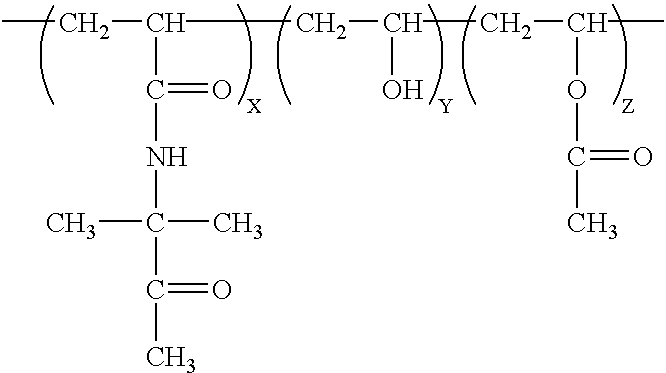

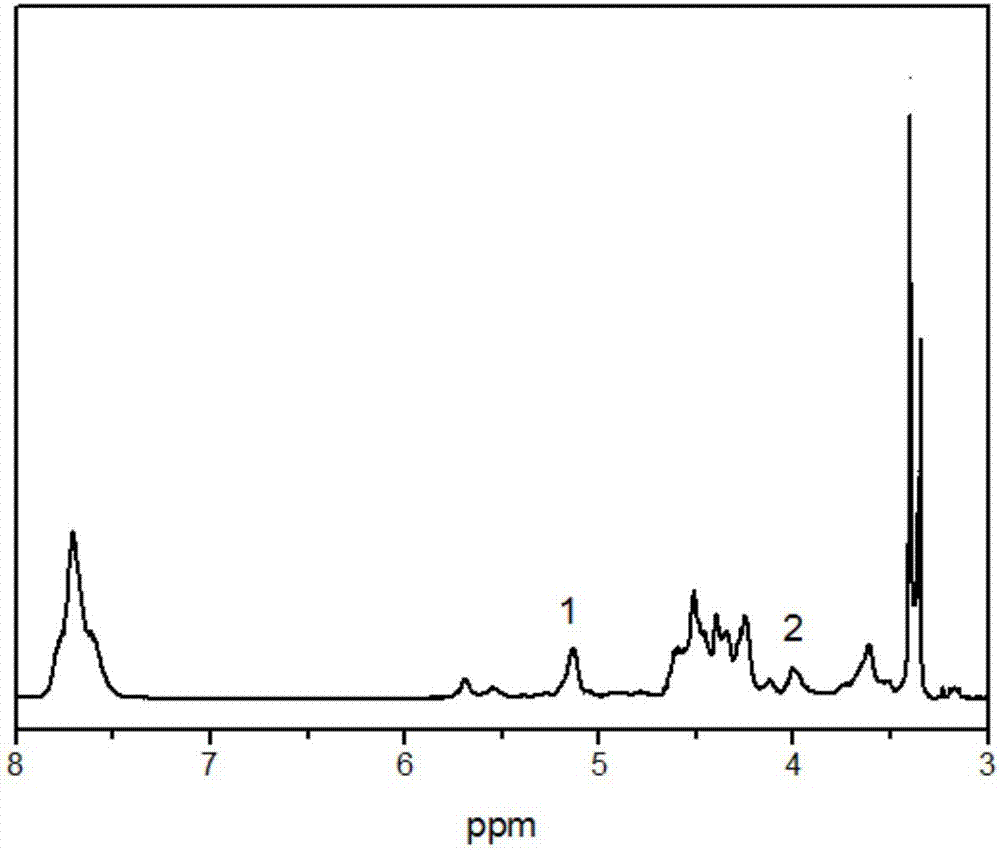

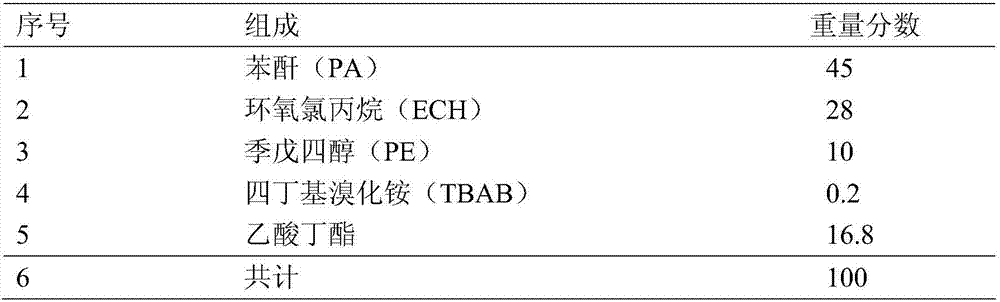

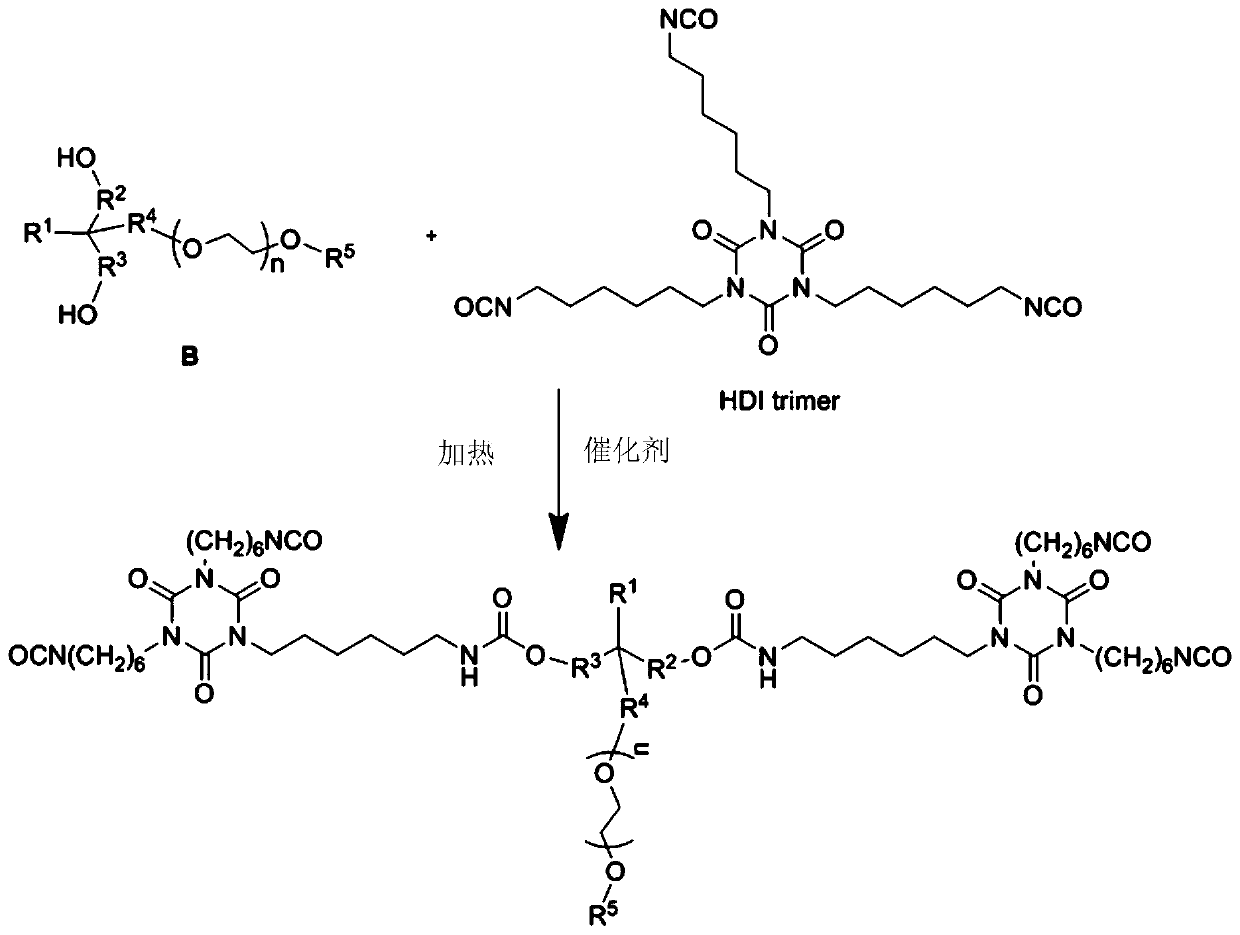

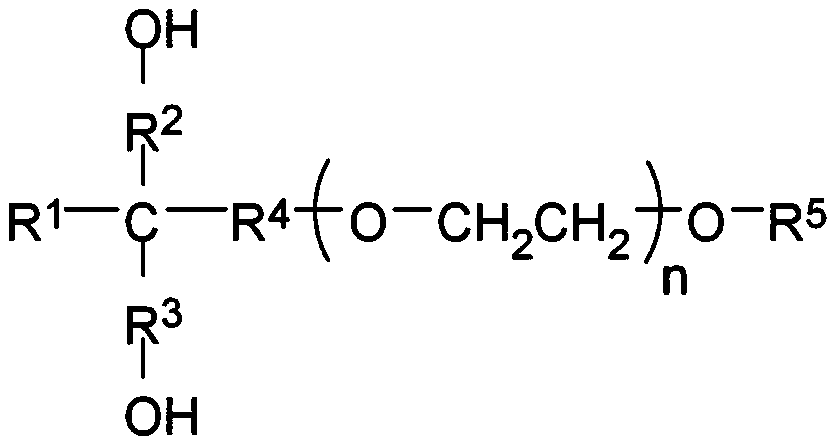

High-crosslinking-density water dispersible nonionic isocyanate curing agent and preparation method thereof

InactiveCN109897153ASimple preparation processIncrease crosslink densityPolyurea/polyurethane coatingsIsocyanateWater dispersible

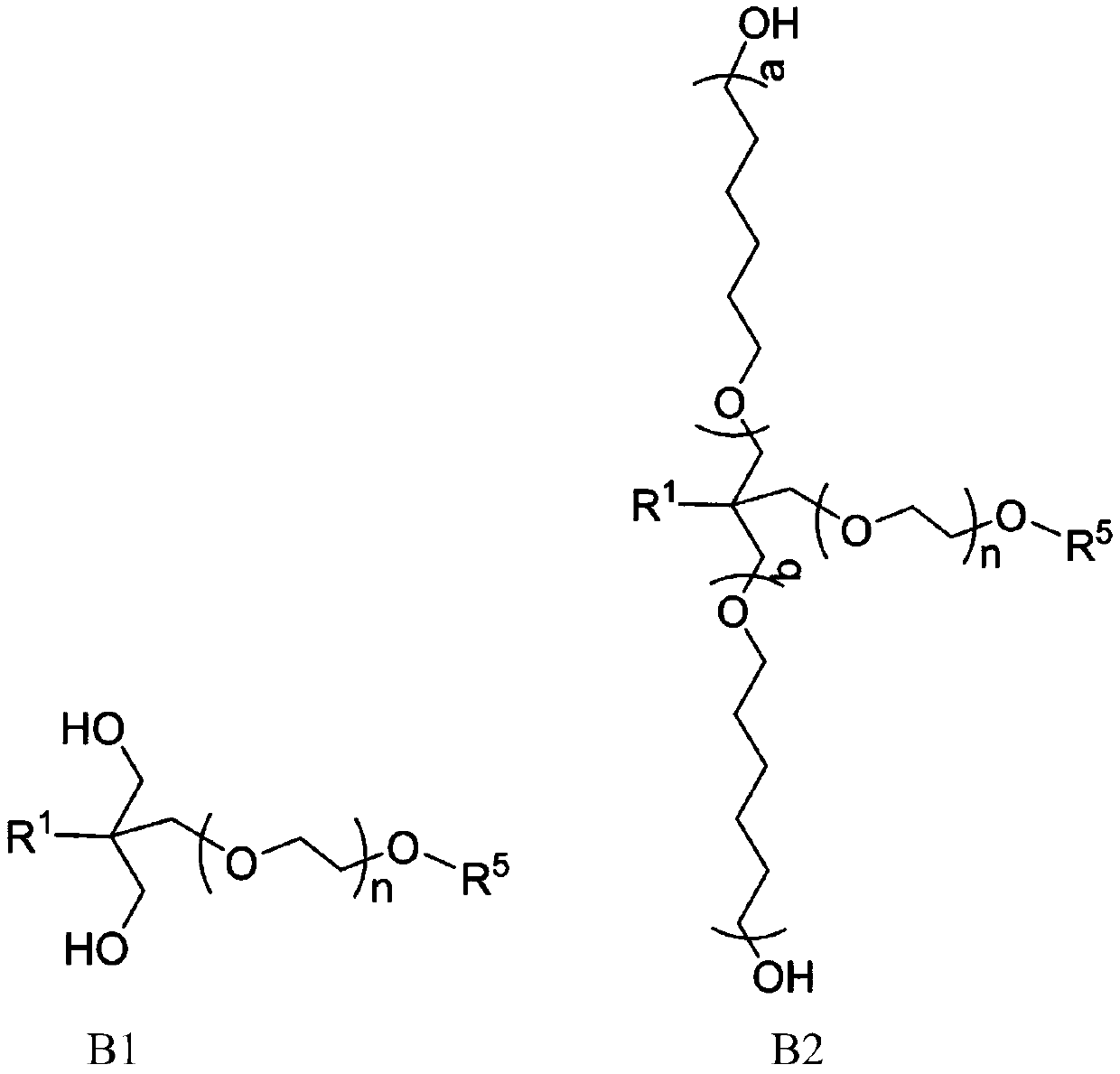

The invention belongs to the technical field of flocculating agents, and discloses a high-crosslinking-density water dispersible nonionic isocyanate curing agent and a preparation method thereof. According to the method, by weight, 70-99 parts of aliphatic polyisocyanate A, 1-30 parts of glycol B with polyether side arms and 0.001-0.5 part of catalysts C are subjected to heating reaction to obtainthe water dispersible nonionic isocyanate curing agent. The molecular structure of the glycol B with the polyether side arms is as shown in the specification, R1 and R5 are same or different monovalent, unsubstituted or substituted alkyls, R2, R3 and R4 are same or different bivalent, unsubstituted or substituted alkyls, and / or the alkyls are spaced by O, S, N or P, and n>5. Hydrophilic polyetherchain segments of the water dispersible nonionic isocyanate curing agent are positioned on the side arms of molecules and easily dispersed in water, and can be cured with hydroxy waterborne resin toobtain a coating with high crosslinking density and excellent water and chemical resistance.

Owner:英德市国彩精细化工有限公司

Plastic material with strong light irradiation resistance

InactiveCN103709548AGood light fastnessHigh resistance to outdoor agingAmmonium polyphosphateMethyl cellulose

The invention discloses a plastic material with strong light irradiation resistance. The plastic material comprises the following materials, by weight, 25-30 parts of polyvinyl chloride resin, 16-27 parts of acrylic resin, 7-13 parts of cellulose, 2-8 parts of methyl cellulose, 1-5 parts of quartz sand, 1-2 parts of iron powder, 3-4 parts of cobalt, 1-2 parts of nickel, 15-23 parts of POE, 6-7 parts of halogen-free intumescent flame retardants, 6-9 parts of ammonium polyphosphate, 9-16 parts of ethene copolymer elastomers, and 5-8 parts of nano calcium carbonate. The light-resistant plastic is advantaged by excellent light resistance, outdoor aging resistance, high production efficiency and the like. The light-resistant plastic has good gloss and color retention, water resistance and chemical resistance. The drying is fast and the construction is convenient. The construction recoating and reworking are easy, and the light-resistant plastic has wide applications in fields of automobile, electric appliance, machinery, building and the like.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Highlight-resistant plastic

The invention discloses a highlight-resistant plastic. The highlight-resistant plastic is characterized by comprising the following substances in parts by weight: 25-30 parts of polyvinyl chloride resin, 6-7 parts of a halogen-free intumescent flame retardant, 6-9 parts of ammonium polyphosphate, 3-5 parts of redispersible latex powder, 2-5 parts of a water repellent agent, 9-16 parts of N-methylpyrrolidone, 7-15 parts of phemethylol, 5-9 parts of semi-hydrated gypsum, 11-23 parts of cellulose, 5-8 parts of rosin-based resin acid, 1-2 parts of aluminum metal powder, 9-16 parts of an ethylene copolymer elastomer and 5-8 parts of nano calcium carbonate. The highlight-resistant plastic disclosed by the invention has the characteristics of excellent light resistance, outdoor aging resistance, high production efficiency and the like, is good in gloss and color retention, water resistance and chemical resistance, can be dried quickly, is convenient for construction, facilitates construction recoating and rework, and can be widely applied to the fields of automobiles, electric appliances, machinery, constructions and the like.

Owner:QINGDAO HAIBAN PLASTIC IND & TRADE

Fireproof corrosion resistant coating

InactiveCN105062288AGood gloss and color retentionGood water and chemical resistanceFireproof paintsAnti-corrosive paintsWeather resistanceAcrylic resin

The invention provides a fireproof corrosion resistant coating. The fireproof corrosion resistant coating has the beneficial effects that thermoplastic acrylic resin, polyurethane resin and organic silicon resin are combined to be used as a main body of the fireproof corrosion resistant coating; through combination of the three kinds of resin, the coating not only has good light and color retention properties and water and chemical resistance but also is convenient to construct, has high drying speed and saves energy; as high temperature resistant mullite and silica fibers are also added to the coating, not only can the mechanical strength of coats be obviously improved but also the weather and corrosion resistance of the coats can be improved; in case of a fire, through synergy of various components in the formula, the coating has good flame retardant effects and is less in fuming.

Owner:章俊

Environmentally friendly stain-resistant sponge brick

InactiveCN109650795AStrong filtering performanceEasy to prepareAuxillary shaping apparatusCeramicwareSoil humidityEnvironmentally friendly

The invention discloses an environmentally friendly stain-resistant sponge brick, which comprises following raw materials in parts by weight: 15 to 20 parts of cement, 16 to 28 parts of aggregate witha particle size of 0.2-0.35 mm, 5 to 8 parts of medium sand with a particle size of 0.35 to 0.5 mm, 1.5 to 4 parts of additive A, 3.2 to 7.8 parts of additive B, 1 to 3 parts of pigment, and 1 part of stain-resistant paint. The provided sponge brick is mainly prepared form cement, aggregate, and medium sand, can be used to build a sponge city, is environmentally friendly and stain resistant, canmaintain the soil humidity at the same time, and improves the vegetation of cities and growth environment of microbes in soil.

Owner:广西宏发海绵城市科技有限公司

Environment-friendly printing Chinese ink

ActiveCN107337959AExcellent water and chemical resistanceImprove frost resistanceInksWeather resistanceCLARITY

The invention belongs to the technical field of preparation of printing Chinese ink, and particularly relates to environment-friendly printing Chinese ink, which comprises the following components in percentage by weight: 15 to 20 percent of a waterborne polyurethane resin, 50 to 60 percent of a modified waterborne polyurethane resin, 1 to 2 percent of a wetting agent, 2 to 4 percent of an antifoaming agent, 1 to 2 percent of a thickening agent, 1 to 2 percent of a flatting agent and 15 to 20 percent of soft water. The printing Chinese ink is high in dry and wet rubbing fastness, water and chemical resistance, freezing resistance, adhesion, yellowing resistance and weather resistance, a formed film is transparent and high in brightness and fullness, and printed images and texts are full and high in clarity.

Owner:昆山大世界油墨涂料有限公司

High-fullness high-distinctness thermosetting acrylic resin and preparation method thereof

InactiveCN103342783AThe ratio is scientific and reasonableImproves image clarity and fullnessPrepolymerButyl acrylate

The invention discloses a high-fullness high-distinctness thermosetting acrylic resin which is prepared from the following raw materials in parts by weight: 15-25% of prepolymer, 15-25% of styrene, 8-20% of n-butyl acrylate, 5-10% of butyl acrylate, 0.1-0.5% of tert-butyl peroxybenzoate and 25-37% of dimethylbenzene. The high-fullness high-distinctness thermosetting acrylic resin disclosed by the invention is composed of the raw materials selected from abundant experiments according to the optimal proportion, and the component proportion is scientific and reasonable. The property detection result indicates that the thermosetting acrylic resin has the characteristics of high gloss, high hardness, high distinctness, high fullness and the like, and can be widely used in the fields of automobiles, electric appliances, mechanics, architecture and the like.

Owner:无锡市南雅化工有限公司

Anti-corrosion wearing resistant coating for transformer and preparation method of anti-corrosion wearing resistant coating

ActiveCN109385166AImprove cooling effectImprove mechanical propertiesAnti-corrosive paintsAcrylic resinTransformer

The invention discloses an anti-corrosion wearing resistant coating for a transformer and belongs to the technical field of transformers. The anti-corrosion wearing resistant coating is prepared fromthe following raw materials in parts by weight: 25-35 parts of a hydroxyl acrylic resin, 8-15 parts of a phenolic resin, 8-12 parts of heat conduction packing, 6-9 parts of a calcium sulfate crystal whisker, 1-3 parts of emery powder, 1-2 parts of talcum powder, 2-5 parts of a silane coupling agent, 0.5-2 parts of lauryl alcohol polyoxyethylene, 0.1-0.2 part of methyl sodium silicate, 1-3 parts ofa lubricant and 15-20 parts of an organic solvent. The anti-corrosion wearing resistant coating is excellent in mechanical property, good in acid, alkali and salt mist resistance and long in servicelife.

Owner:国网河南省电力公司桐柏县供电公司

Ultra-heat-resistant high-temperature-resistant coating for exhaust equipment

InactiveCN105949963AImprove liquidityImprove deposition efficiencyFireproof paintsEpoxy resin coatingsGlycerolDibenzoyl Peroxide

The invention discloses an ultra-heat-resistant high-temperature-resistant coating for exhaust equipment. The coating is made from the following raw materials: fine magnesia powder, an epoxy phenol novolac resin F51, a bisphenol epoxy resin, n-butanol, a modified aliphatic curing agent 2280, nanometer chitin, tributyl citrate, glycerol, asbestos powder, waste ceramics powder, coal ash, dimethyl siloxane, sepiolite fabric, aluminium powder, sodium tripolyphosphate, styrene, azodiisobutyronitrile, a rare earth coupling agent, palmitic acid, a styrene-acrylic emulsion, butyl methacrylate, polyvinyl alcohol, benzoyl peroxide and a proper amount of absolute ethanol. The coating has excellent water resistance and chemical resistance and wear resistance, and is fast to dry and convenient to apply. Through addition of nanometer chitin and asbestos powder, compactness of a coating film is improved, and thermal resistance and high temperature resistance of the coating are improved. The coating is easy to apply, has good adhesion to a material, and is not easy to burn.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

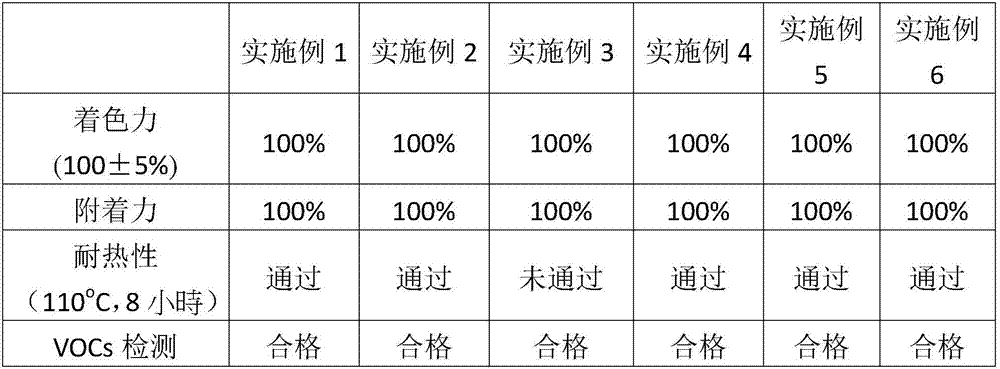

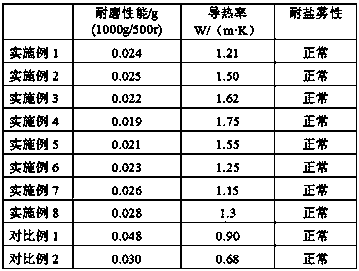

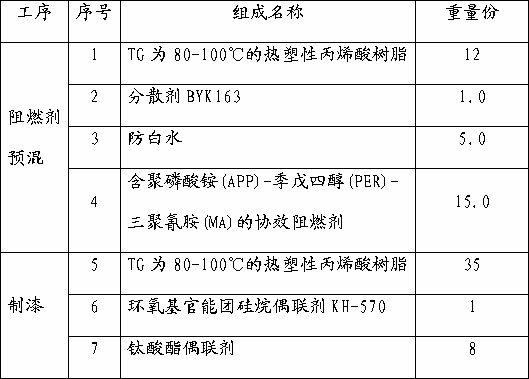

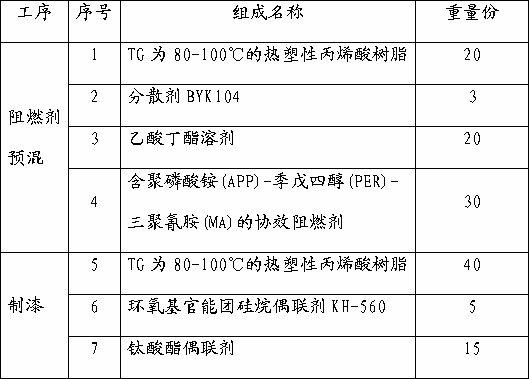

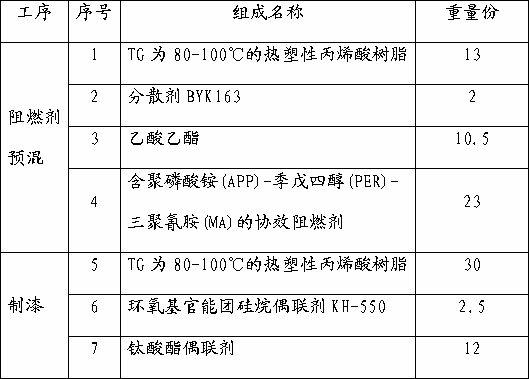

Plastic veneer type thermoplastic acrylic environment-friendly fireproof paint and method for preparing and using same

The invention provides a plastic veneer type thermoplastic acrylic environment-friendly fireproof paint and a method for preparing and using same. The environment-friendly fireproof paint is prepared by using thermoplastic acrylic resin as the primary material with halogen-free synergistic flame retardant ammonium polyphosphate (APP)- pentaerythritol (PER)- melamine(MA), adding a little coupling agent, dispersing auxiliary, pigment and proper solvent under a proper process. The environment-friendly fireproof paint can be used for coating plastic enclosures such as HIPS (High Impact Polystyrene), PS (Polystyrene), ABS (Acrylonitrile Butadiene Styrene), PMMA (Polymethyl Methacrylate), and can form a paint film with excellent fireproof effects after proper constructing and drying, so that fireproof and decoration purposes are achieved. The paint has the characteristics of a thermoplastic acrylic resin paint such as safety and environment protection, easy construction and re-construction, excellent adhesion, strong colour retention decoration, good waterproof performance, good chemical resistance and the like, thus, the fireproof level can reach UL94V-0 level; moreover, the paint is free of halogen and heavy metal, and the smoke quantity in a combustion process is very low, thus, the paint is an environment-friendly fireproof paint with high performances and high efficiency .

Owner:深圳市嘉卓成科技发展有限公司

Anti-aging coating for battery cover plate of new-energy automobile

The invention discloses an anti-aging coating for a battery cover plate of a new-energy automobile. The anti-aging coating comprises the following raw materials in parts by weight: 30-40 parts of polysulfide rubber, 20-28 parts of polytetrafluoroethylene gum, 5-8 parts of terpene resin, 3-6 parts of sebacicdihydrazide, 3-6 parts of high-pigment carbon black, 3-6 parts of zinc borate, 0.2-0.3 partof ninhydrin, 0.2-0.3 part of stannous oxide, 0.5-0.8 part of diatomite, 0.5-0.8 part of semi-reinforcing furnace black SRF, 0.2-0.3 part of aluminium nitride, 0.5-0.8 part of shellac, 0.1-0.2 part ofsulfur, 2-3 parts of ethylicin, 0.1-0.2 part of chlorinated paraffin, 0.1- 0.2 part of 1, 2-dimethylimidazole and 0.1-0.2 part of rare earth cerium fluoride. After adoption of a formula, the anti-aging automobile coating has good gloss and color retention and water and chemical resistance, and is fast in drying and convenient to construct; the anti-aging automobile coating has improved light aging resistance and paint film strength.

Owner:ANHUI HEYI NEW ENERGY VEHICLE CHARGING EQUIP CO LTD

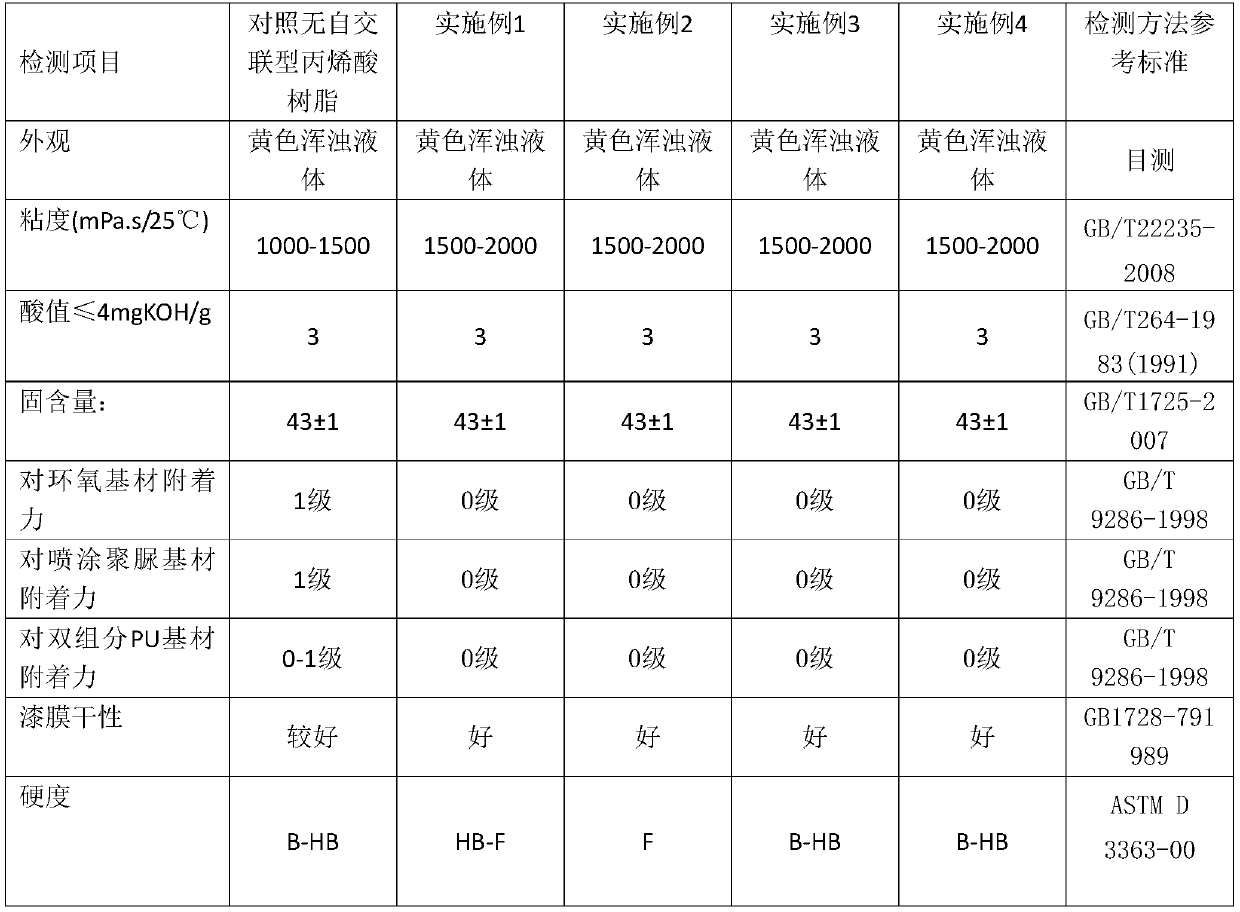

High-adhesion room-temperature self-crosslinking acrylic resin, and preparation method and application thereof

ActiveCN111057187AIncrease crosslink densityImprove adhesionGraft polymer adhesivesPriming paintsEpoxyPolymer science

The invention relates to a resin, and a preparation method and an application thereof, and discloses a high-adhesion room-temperature self-crosslinking acrylic resin, and a preparation method and an application thereof. The resin is prepared from, by weight, 15 to 22 parts of methyl methacrylate, 12 to 18 parts of butyl methacrylate, 3 to 7 parts of butyl acrylate, 0.3 to 1 part of acrylic acid, 2to 5 parts of high chlorinated polypropylene resin, 1 to 5 parts of ethyl isocyanate acrylate, 0.2 to 0.5 part of di-tert-butyl peroxide and 40 to 65 parts of an organic solvent. The high-adhesion room-temperature self-crosslinking acrylic resin can be used to prepare various kinds of paints or can be directly brushed, has the advantages of good film-forming property, excellent water resistance and chemical resistance, easiness in construction and high adhesive force, and particularly has strong adhesive force on spraying polyurea, epoxy resin, bi-component PU and other base materials, so that the resin is particularly suitable for being used as an interlayer overlapping agent of epoxy resin or spraying polyurea or bi-component PU and other base materials.

Owner:广东华珀科技有限公司

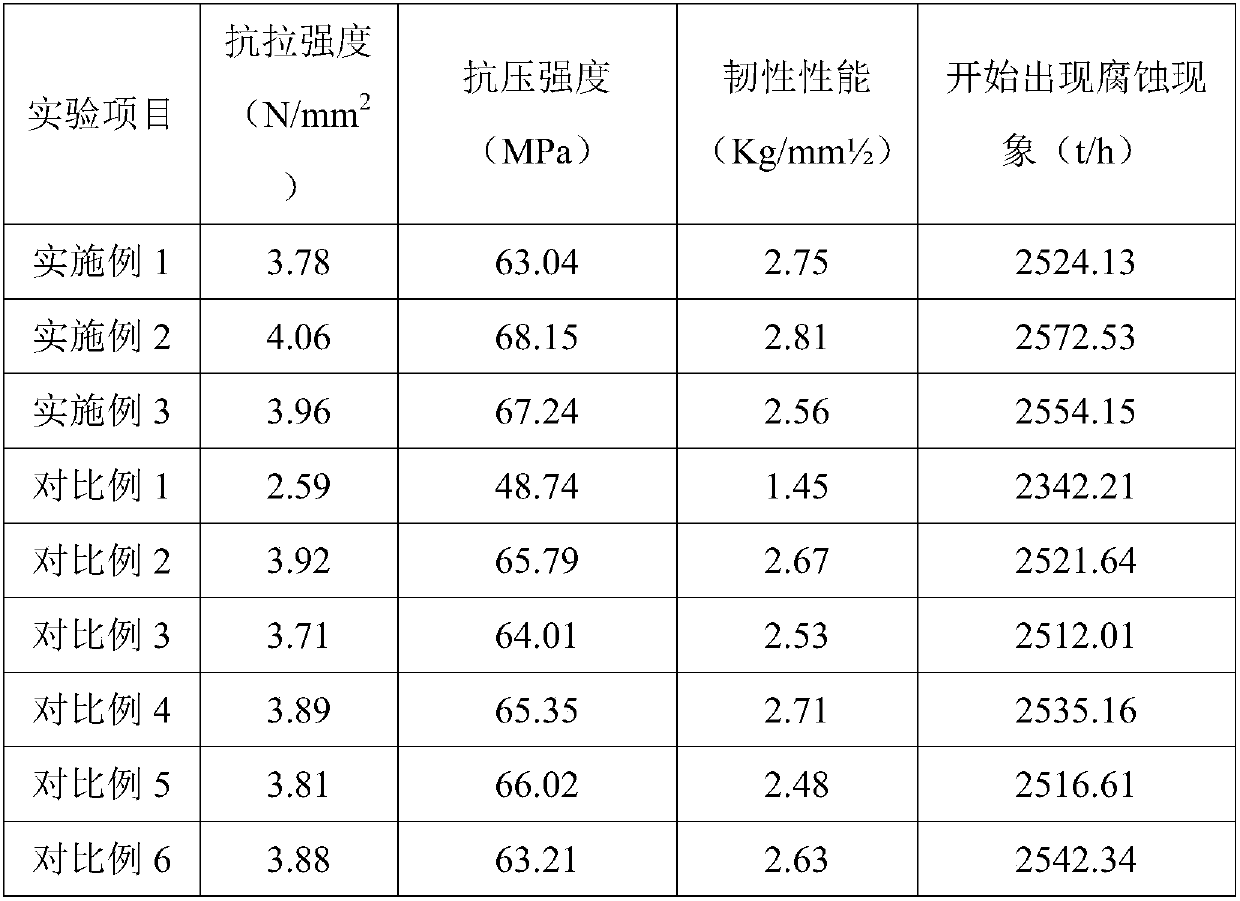

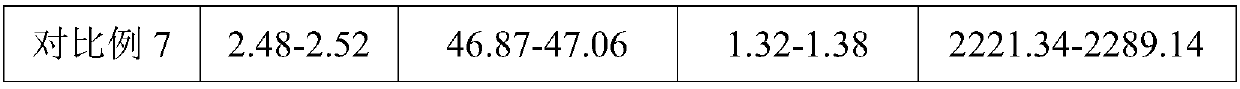

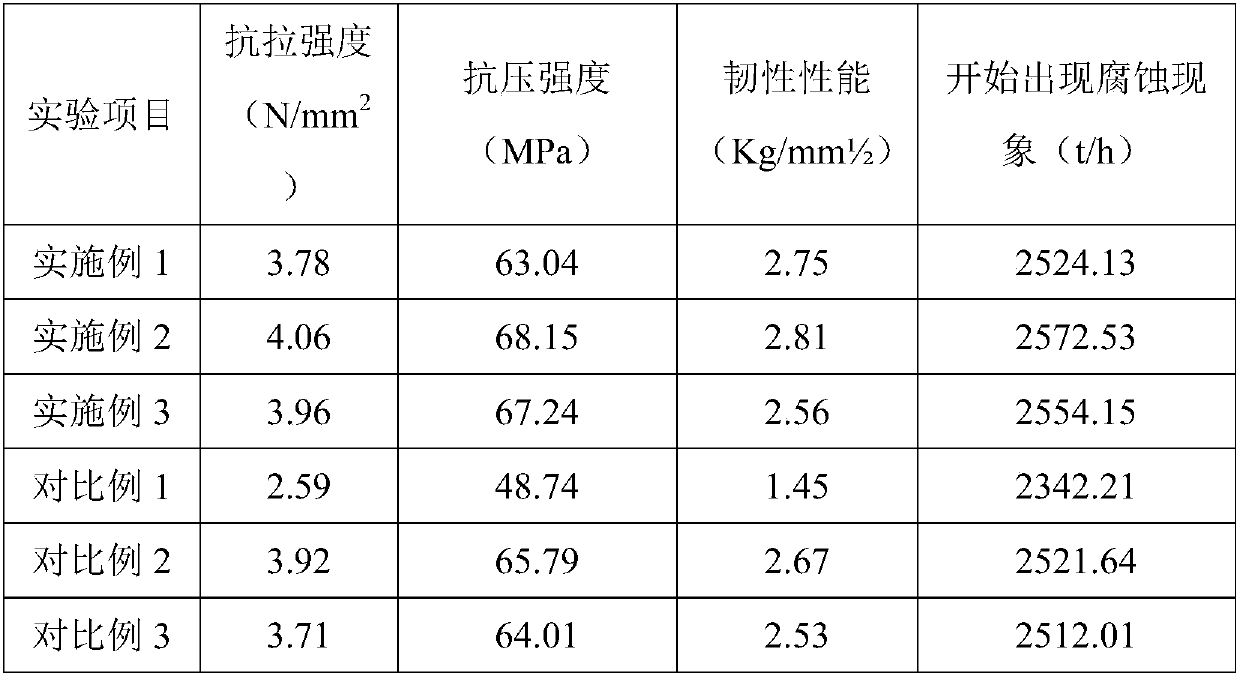

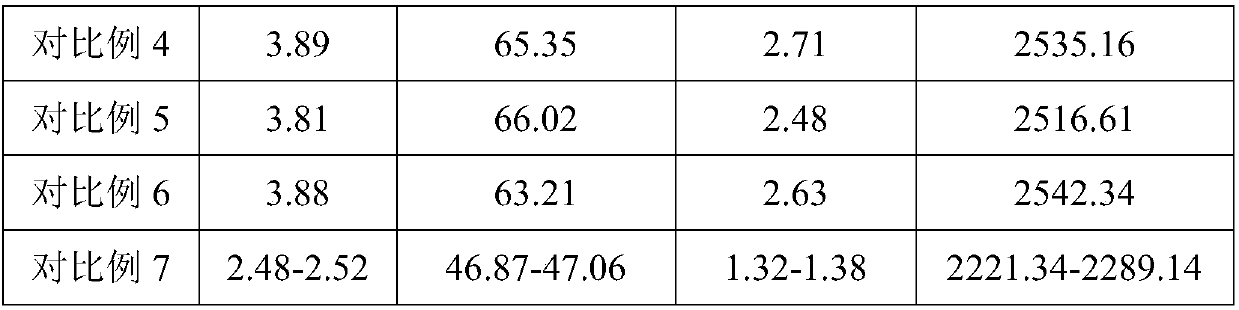

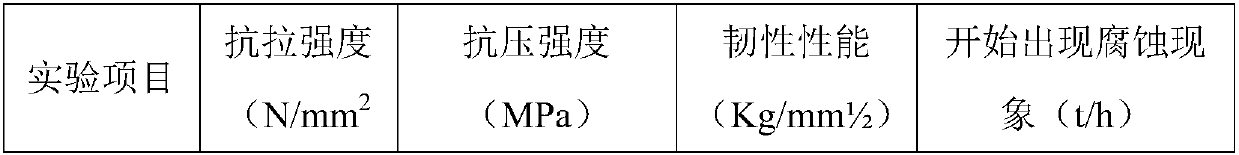

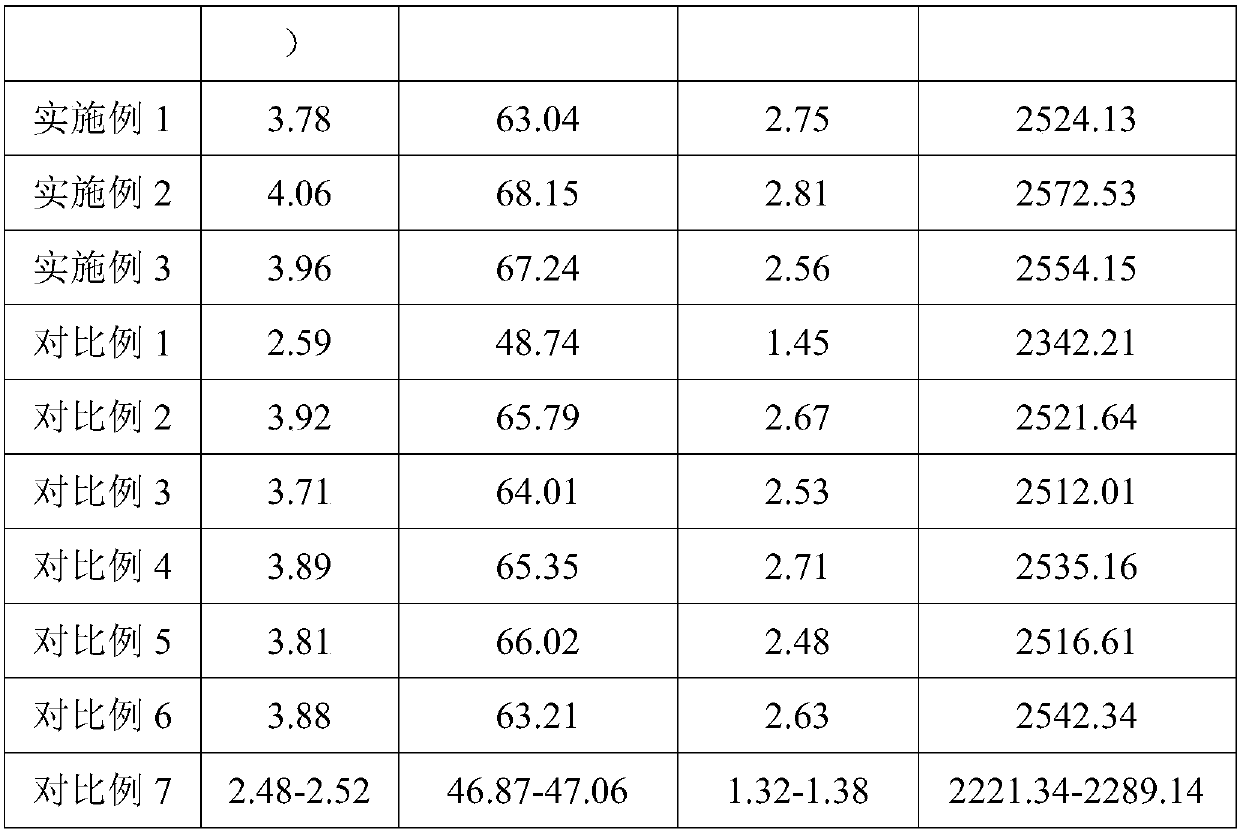

Concrete

The invention discloses a concrete, which belongs to the technical field of concrete preparation. The concrete comprises the following raw materials in parts by weight: 140 parts of cement, 28 parts of sand, 25 parts of stone, 350 parts of water, and 18 parts of paper bars , 22 parts of rice straw, 15 parts of hemp knife, 12 parts of polypropylene fiber, 6 parts of polyphenol aldehyde, 18 parts of polysulfone resin, poly[(2-oxirane)-1,2-cyclohexanediol] 2 8 parts of ‑ethyl‑2‑(hydroxymethyl)‑1,3‑propylene glycol ether, 10 parts of SJ‑101 resin, 5 parts of zinc trimeracrylate. The concrete prepared by the invention has high tensile strength and compressive strength, and excellent toughness and corrosion resistance.

Owner:广西丰达三维科技有限公司

Modified waterborne polyurethane resin as well as preparation method and application thereof

ActiveCN112175162AIncrease graftingIncrease polarityPolyurea/polyurethane coatingsPolymer scienceLacquer

The invention provides modified waterborne polyurethane resin as well as a preparation method and an application thereof. The resin is prepared by reaction of an isocyanate-terminated prepolymer and amodified monomer. The preparation method comprises the following steps of: synthesizing the isocyanate-terminated prepolymer, fully mixing and dissolving a monomer with a modification function and the isocyanate-terminated prepolymer, dispersing under high-speed shearing to obtain a pre-modified emulsion after neutralization reaction, and adding an initiator into the pre-modified emulsion to initiate polymerization. The polyurethane resin provided by the invention can be used in the field of paint, especially wood lacquer, the preparation process of the modified waterborne polyurethane resinprepared by the preparation method provided by the invention is simple and controllable, the synthesized resin has high solid content and small particle size, and the application performance requirements in the field of wood lacquer are met.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

Method of producing hollow silica microparticles

ActiveUS20120111231A1Good adhesivenessIncrease resistancePigmenting treatmentMaterial nanotechnologySilane compoundsSilanes

A method of producing hollow silica microparticles that suppress whitening of a transparent coating film and show excellent abrasion resistance and adhesiveness. The method includes preparation of an organosol in which hollow silica microparticles are dispersed with the silica concentration of 1 to 70 W % and addition of a silane compound and an alkali catalyst to the organosol at a temperature in the range from 30° C. to 300° C. to react the silane compound to the hollow silica microparticles under the condition where a quantity of water against the added silica (the hollow silica microparticles) is in the range from 0.1 to 50 W %.

Owner:JGC CATALYSTS & CHEM LTD

Formula and preparation method of animal marking paint

InactiveCN107353735AGood gloss and color retentionGood water and chemical resistanceEpoxy resin coatingsEpoxyAcrylic resin

The invention discloses a formula of an animal marking paint. The animal marking paint comprises the following raw materials in percentage by weight: 12-24% of acrylic resin, 15-21% of epoxy resin, 8-14% of organic solvent, 2-8% of organobentonite, 0.6-1.2% of emulsifier, 0.3-0.9% of dispersing agent, 0.3-0.6% of coloring agent and 48-68% of water. The animal marking paint is processed and prepared in a stirring / heating mixed manner. According to the invention, the acrylic resin and the epoxy resin are used as main raw materials; the acrylic resin has favorable gloss and color retention property, water resistance, chemical resistance and quick drying property; the epoxy resin has favorable chemical resistance, especially alkali resistance, and is high in paint film adhesion force and favorable in color retention property; and the above raw materials are safe and reliable, have no toxicity or pungent odor, and can not do harm to animals or the environment.

Owner:潘礼斌

Anticorrosive power transmission tower outer coating

ActiveCN109370339AImprove cooling effectImprove mechanical propertiesAnti-corrosive paintsPolyurea/polyurethane coatingsWear resistantPolyvinyl alcohol

The invention discloses an anticorrosive power transmission tower outer coating and belongs to the technical field of power circuits. The anticorrosive power transmission tower outer coating is prepared from the following raw materials in parts by weight: 30-40 parts of hydroxy acrylic resins, 15-25 parts of polyurethane emulsion, 8-12 parts of a thermal conductive filler, 1-3 parts of calcium sulfate whiskers, 1-3 parts of molybdenum powder, 0.5-1.5 parts of asbestos powder, 0.1-0.2 part of an ultraviolet light absorber, 0.1-0.5 part of sodium methyl silicate, 1-3 parts of polyvinyl alcohol,1-3 parts of polydimethylsiloxane, 1-3 parts of glycerin monostearate and 15-25 parts of an organic solvent. The coating is wear-resistant, acid and alkali resistant, salt spray resistant, excellent in mechanical property and long in service life.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Formula of concrete for buildings

The invention discloses a formula of concrete for construction, which belongs to the technical field of concrete preparation. The formula of concrete for construction includes the following raw materials: cement, sand, stone, water, paper tendon, straw, hemp knife, polypropylene Fiber, polyphenol novolac, polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)-1,3-propylene glycol ether , SJ-101 resin, zinc trimer acrylate. The building concrete prepared by the invention has high tensile strength and compressive strength, and excellent toughness and corrosion resistance.

Owner:广西丰达三维科技有限公司

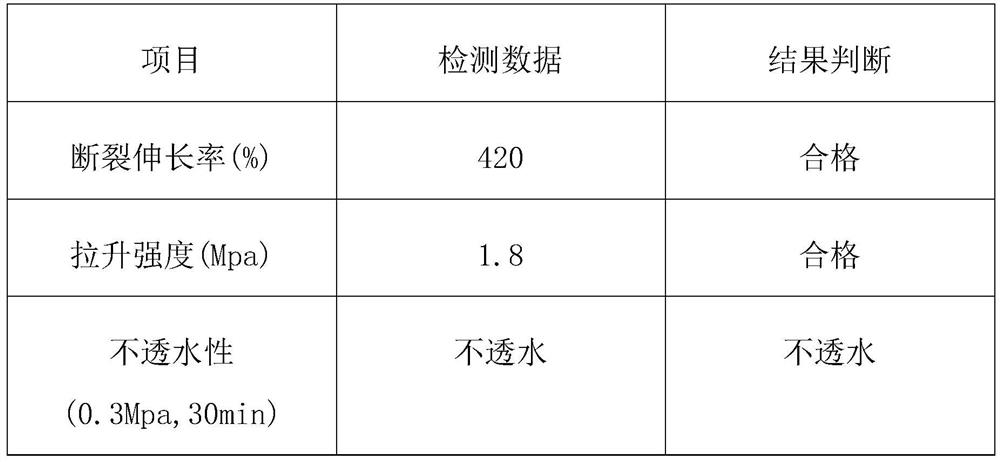

Nano waterproof material for buildings and preparation method thereof

InactiveCN112457728AGood gloss and color retentionGood water and chemical resistanceCoatingsEmulsionAntifoam agent

The invention provides a nano waterproof material for buildings and a preparation method thereof, and relates to the technical field of building materials. The invention discloses a nano waterproof material for buildings. The nano waterproof material is prepared from the following components: acrylic resin, silicone acrylic emulsion, Texanol, diatomite, nano titanium dioxide, nano silica powder, adispersing agent, an antifoaming agent, a bactericide and water. The material is excellent in waterproof performance and long in service life. In addition, the invention further provides a preparation method of the nano waterproof material for the building. The preparation method comprises the following steps: preparing a mixed emulsion, mixing the filler and the auxiliary agent, and preparing afinished product. The method is simple in process, and the prepared product is good in waterproof performance and long in service life.

Owner:WEIFANG UNIV OF SCI & TECH

High-performance concrete

The invention discloses a high-performance concrete, which belongs to the technical field of concrete preparation. The high-performance concrete includes the following raw materials: cement, sand, stone, water, paper tendon, rice straw, hemp knife, polypropylene fiber, polystyrene Phenolic, polysulfone resin, poly[(2-oxiranyl)-1,2-cyclohexanediol] 2-ethyl-2-(hydroxymethyl)-1,3-propylene glycol ether, SJ-101 Resin, zinc trimer acrylate. The high-performance concrete prepared by the invention has high tensile strength and compressive strength, and excellent toughness and corrosion resistance.

Owner:广西丰达三维科技有限公司

Composite floor material for municipal roads and preparation method thereof

The invention discloses a composite floor material for municipal roads and a preparation method thereof, and belongs to the technical field of preparation of floor materials. The composite floor material for the municipal roads comprises the following raw materials: organosilicone-modified polyurethane, bisphenol F-type epoxy resin, polytetrafluoroethylene resin, montmorillonite powder, magnesiumoxide, dioctyl phthalate, tridecyl isononanoate, diethanolamide cocoate, polyethylene fiber, polyacrylic acid, N,N-dimethylcyclohexylamine, 2,5-dimethyl-2,5-bis(t-butylperoxy)hexane and sodium dodecylallyl sulfosuccinate. The composite floor material for the municipal roads is prepared according to the following steps: crushing, mixing, cooling and the like. Through optimization of raw materials of the conventional composite floor material for the municipal roads as well as using amounts thereof, the compressive strength, the flexural strength and the tensile strength of the material are improved, so that using requirements of the composite floor material for the municipal roads can be met.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Antirust high-temperature-resistant water paint additive

InactiveCN109897433AImprove high temperature resistanceImprove practicalityFireproof paintsAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses an antirust high-temperature-resistant water paint additive. The antirust high-temperature-resistant water paint additive comprises the following components in parts by weight:20-30 parts of zinc oxide, 5-10 parts of fatty alcohol polyoxyethylene ether, 20-30 parts of acrylic resin, 5-10 parts of amino resin, 5-10 parts of epoxy resin, 2-5 parts of polyurethane, 3-5 partsof ammonium polyphosphate, 5-10 parts of phytate and 3-5 parts of carboxymethyl cellulose. According to the antirust high-temperature-resistant water paint additive, the acrylic resin, the amino resin, the epoxy resin and the polyurethane are mutually matched, and thus, a coating has the advantages of good light and color retention, water resistance, chemical resistance, quick drying and convenience in construction, re-coating and reworking, by addition of the ammonium polyphosphate, the high-temperature resistance of the additive is enhanced, and the practicability of the additive is improved; in a high-temperature environment, the additive can be used normally, and the performance and the quality of paint are still not influenced; and by addition of the zinc oxide and the phytate, the corrosion resistance of the additive is improved. The problem of rust on the surface of a coated article is avoided.

Owner:安徽名士达新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com