Anti-corrosion wearing resistant coating for transformer and preparation method of anti-corrosion wearing resistant coating

An anti-corrosion and wear-resistant, transformer technology, applied in the field of transformers, can solve problems such as improving heat dissipation performance, and achieve the effects of increasing mechanical performance, good heat dissipation effect, and increasing heat conduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

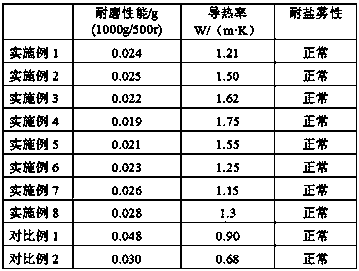

Examples

Embodiment 1

[0023] An anti-corrosion and wear-resistant coating for transformers, which is made of the following raw materials in parts by weight: 25 parts of hydroxyacrylic resin, 15 parts of phenolic resin, 8 parts of thermal conductive filler, 9 parts of calcium sulfate whiskers, 1 part of corundum powder, and 2 parts of talc powder 1 part, 2 parts of silane coupling agent KH550, 0.5 part of polyoxyethylene lauryl ether, 0.1 part of sodium methyl silicate, 1 part of lubricant, and 15 parts of organic solvent.

[0024] The thermally conductive filler is formed by mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker in a weight ratio of 1:1:1; the preparation method of the thermally conductive filler includes the following steps: mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker After mixing evenly, stir evenly with an ethanol solution whose weight fraction is 8% stearic acid twice, and calcined at 90-100°C to obtain a thermally conductive filler.

[...

Embodiment 2

[0031] An anti-corrosion and wear-resistant coating for transformers, which is made of the following raw materials in parts by weight: 26 parts of hydroxyacrylic resin, 12 parts of phenolic resin, 9 parts of thermally conductive filler, 8 parts of calcium sulfate whiskers, 1.2 parts of corundum powder, and 1.8 parts of talc powder 3 parts, 3 parts of silane coupling agent KH550, 0.8 parts of polyoxyethylene lauryl ether, 0.12 parts of sodium methyl silicate, 1 part of lubricant, and 16 parts of organic solvent.

[0032] The thermally conductive filler is formed by mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker in a weight ratio of 1:1:1; the preparation method of the thermally conductive filler includes the following steps: mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker After mixing evenly, stir evenly with 2.5 times the ethanol solution whose weight mass fraction is 8% stearic acid, and calcinate at 90-100°C to obtain a thermally c...

Embodiment 3

[0039] An anti-corrosion and wear-resistant coating for transformers, made of the following raw materials in parts by weight: 28 parts of hydroxyacrylic resin, 11 parts of phenolic resin, 10 parts of thermally conductive filler, 7 parts of calcium sulfate whiskers, 1.5 parts of corundum powder, and 1.5 parts of talc powder 3 parts, 3 parts of silane coupling agent KH550, 1.0 parts of polyoxyethylene lauryl ether, 0.15 parts of sodium methyl silicate, 1.5 parts of lubricant, and 17 parts of organic solvent.

[0040] The thermally conductive filler is formed by mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker in a weight ratio of 2:1:1; the preparation method of the thermally conductive filler includes the following steps: mixing titanium dioxide, nano-zinc oxide, and silicon nitride whisker After mixing evenly, stir evenly with 2.5 times the ethanol solution whose weight mass fraction is 9% stearic acid, and calcinate at 90-100°C to obtain a thermally conduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com