Modified waterborne polyurethane resin as well as preparation method and application thereof

A water-based polyurethane and polyurethane resin technology, applied in the field of wood paint coatings, can solve the problems of difficulty in preparing small particle size transparent emulsion, unable to meet the performance requirements of wood paint, and difficult for customers to meet performance requirements, and achieve excellent adhesion effect, High construction efficiency and good thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

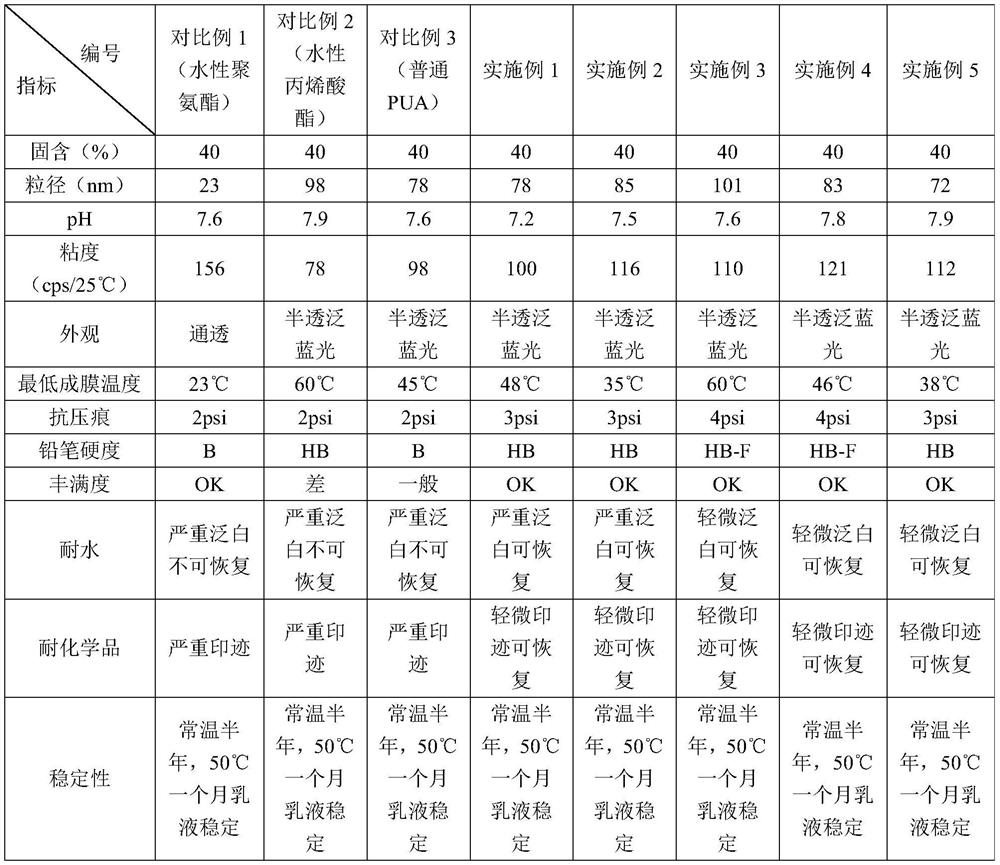

Examples

Embodiment 1

[0100] Add 72g HMDI (dicyclohexylmethane diisocyanate), 100g PTMEG1000 (polytetrahydrofuran ether glycol), 0.06g8108 catalyst, heat up to 80°C for 1h, cool down to below 60°C, add 5.4g trimethylolpropane, 14.6g dimethylolpropane Propionic acid, 1.2g of 1,4-butanediol, and 58g of acetone were heated to 75°C for reaction. Samples were taken every 1 hour to measure NCO until the NCO reached the theoretical value and the reaction was stopped.

[0101] Cool down to below 60°C (between 50-60°C), add 130g acetone, 11.6g tetrahydrofuran acrylate, 23.2g 3-amino-4,4,4-trifluorobutenoic acid ethyl ester, 46.4g styrene, 150.8g Methyl methacrylate, mix to dissolve.

[0102] Lower the temperature to below 40°C and add 11g of triethylamine, and time the reaction for 5 minutes.

[0103] The prepared prepolymer was poured into a dispersion cup, and 638 g of water was added under a high-speed shear condition of 1500 r / min to obtain a water-based polyurethane-acrylate mixed emulsion. Then 2....

Embodiment 2

[0107] Add 86g HMDI (dicyclohexylmethane diisocyanate), 100g PPG2000 (polypropylene oxide ether glycol), 0.06g8108 catalyst, heat up to 80°C for 1h, cool down to below 60°C, add 6g trimethylolpropane, 16g dimethylol Propionic acid, 2g 1,4-butanediol, 60g acetone, heat up to 75°C for reaction, take samples every 1h to measure NCO, until NCO reaches the theoretical value, stop the reaction.

[0108] Cool down to below 60°C (between 50-60°C), add 134g acetone, 12.5g tetrahydrofuran acrylate, 25g 3-amino-4,4,4-trifluorobutenoic acid ethyl ester, 50.4g styrene, 164.1g formazan methyl acrylate, mix to dissolve.

[0109] Cool down to below 40°C and add 12.06g of triethylamine to neutralize for 5 minutes.

[0110] The prepared prepolymer was poured into a dispersion cup, and 693g of water was added under the condition of high shear of 1500r / min to obtain a water-based polyurethane-acrylate mixed emulsion, and then 2.8g of ethylenediamine was added for chain extension reaction.

[...

Embodiment 3

[0114] Add 86g HMDI (dicyclohexylmethane diisocyanate), 100g PTMEG2000 (polytetrahydrofuran ether glycol), 0.06g8108 catalyst, heat up to 80°C for 1h, cool down to below 60°C, add 6g trimethylolpropane, 16g dimethylolpropionic acid , 2g 1,4-butanediol, 60g acetone, heat up to 75°C to react, take samples every 1h to measure NCO, until NCO reaches the theoretical value, stop the reaction.

[0115] Cool down to below 60°C (between 50-60°C), add 134g acetone, 14.7g tetrahydrofuran acrylate, 29.4g 3-amino-4,4,4-trifluorobutenoic acid ethyl ester, 58.8g styrene, 186.1g Methyl methacrylate, mix to dissolve.

[0116] Cool down to below 40°C and add 12.06g of triethylamine to neutralize for 5 minutes.

[0117] The prepared prepolymer was poured into a dispersing cup, and 753 g of water was added under a high-speed shear condition of 1500 r / min to obtain a water-based polyurethane-acrylate mixed emulsion, and then 2.8 g of ethylenediamine was added for chain extension reaction.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com