Plastic veneer type thermoplastic acrylic environment-friendly fireproof paint and method for preparing and using same

A thermoplastic acrylic and fire retardant coating technology, applied in the direction of fire retardant coatings, coatings, etc., can solve the problems of difficult use, complicated operation and processing of reactive flame retardants, etc., and achieve convenient construction, good gloss and color retention, and anti-aging. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

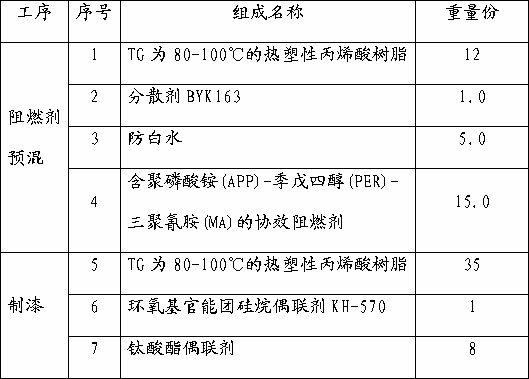

[0067] 1. The composition of the fire retardant coating:

[0068] Colorless fire retardant coating

[0069]

[0070] 2. Supporting diluent, including various components in the following parts by weight:

[0071] Anti-white water: 5 parts; diacetone alcohol: 5 parts; n-butanol: 5 parts;

[0072] Ethyl acetate: 45 parts; Methylal: 5 parts.

[0073] 3. Preparation method of fire retardant coating:

[0074] 1) Mixing and dispersion of fire protection additives:

[0075] Mix the thermoplastic acrylic resin with a TG of 80-100°C and the dispersant BYK163 according to the stated ratio, and add the solvent to prevent white water. At a speed of 400rpm, slowly add ammonium polyphosphate (APP)-pentaerythritol (PER)- After adding the synergistic flame retardant of melamine (MA), increase the rotating speed to 1000rpm, and disperse until the fineness reaches below 15μm for later use;

[0076] 2) Paint making:

[0077] Take a clean paint tank, add thermoplastic acrylic resin with a...

Embodiment 2

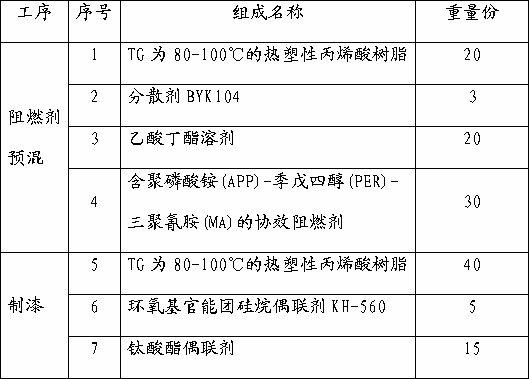

[0080] 1. The composition of the fire retardant coating:

[0081] Colorless fire retardant coating

[0082]

[0083] 2. Supporting diluent, including various components in the following parts by weight:

[0084] Anti-white water: 20 parts; diacetone alcohol: 20 parts; n-butanol: 20 parts;

[0085] Ethyl acetate: 60 parts; Methylal: 15 parts.

[0086] 3. Preparation method of fire retardant coating:

[0087] 1) Mixing and dispersion of fire protection additives:

[0088] Mix the thermoplastic acrylic resin with a TG of 80-100°C and the dispersant according to the stated ratio, add butyl acetate solvent, and slowly add ammonium polyphosphate (APP)-pentaerythritol (PER)- Melamine (MA) synergistic flame retardant, after adding, increase the rotating speed to 1400rpm, disperse until the fineness reaches below 15 μm, and set aside;

[0089] 2) Paint making:

[0090] Take a clean paint tank, add thermoplastic acrylic resin with a TG of 80-100°C and the fire prevention additi...

Embodiment 3

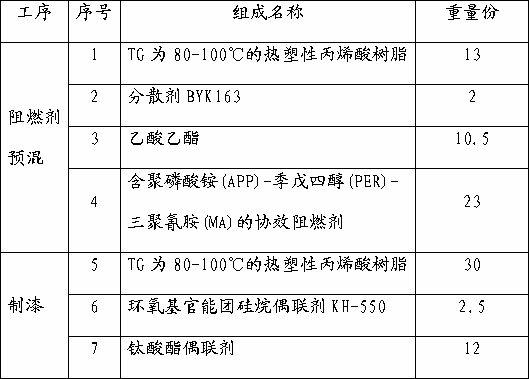

[0092] 1. The composition of the fire retardant coating:

[0093] Colorless fire retardant coating

[0094]

[0095] 2. Supporting diluent, including various components in the following parts by weight:

[0096]Anti-white water: 12 parts; diacetone alcohol: 13 parts; n-butanol: 10 parts;

[0097] Ethyl acetate: 50 parts; Methylal: 10 parts.

[0098] 3. Preparation method of fire retardant coating:

[0099] 1) Mixing and dispersion of fire protection additives:

[0100] Mix the thermoplastic acrylic resin with a TG of 80-100°C and the dispersant according to the stated ratio, and add ethyl acetate solvent, at a speed of 600rpm, slowly add the synergistic flame retardant in proportion, after the addition is complete, increase the speed to 1200rpm, disperse until the fineness is below 15μm, and set aside;

[0101] 2) Paint making:

[0102] Take a clean paint tank, add thermoplastic acrylic resin with a TG of 80-100°C, and the fire prevention additives, silane coupling ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com