Production equipment for tailing micro powder

A technology of tailings micro-powder and production equipment, which is applied in the directions of grain processing, climate sustainability, sustainable waste treatment, etc., can solve problems such as difficult utilization of tailings, achieve the effects of saving manpower and material resources, facilitating operation, and strengthening the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

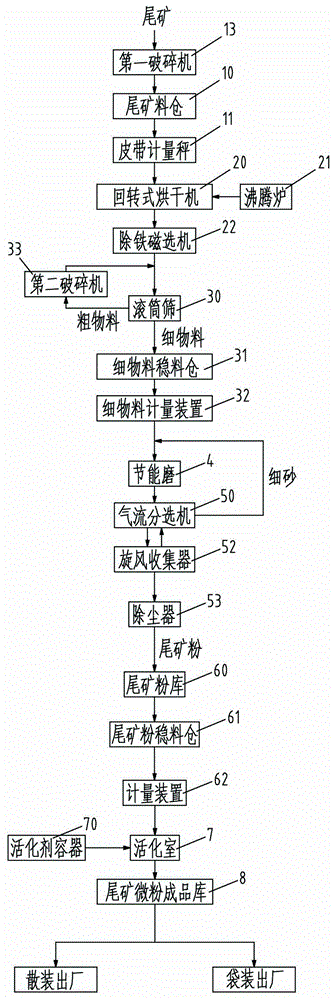

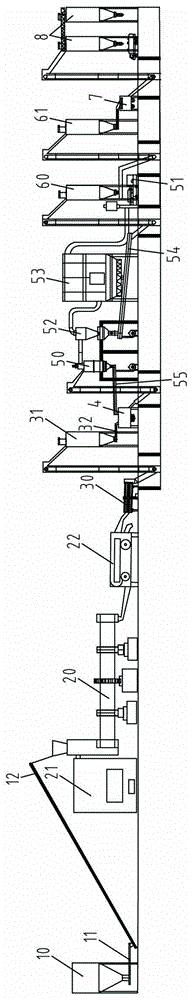

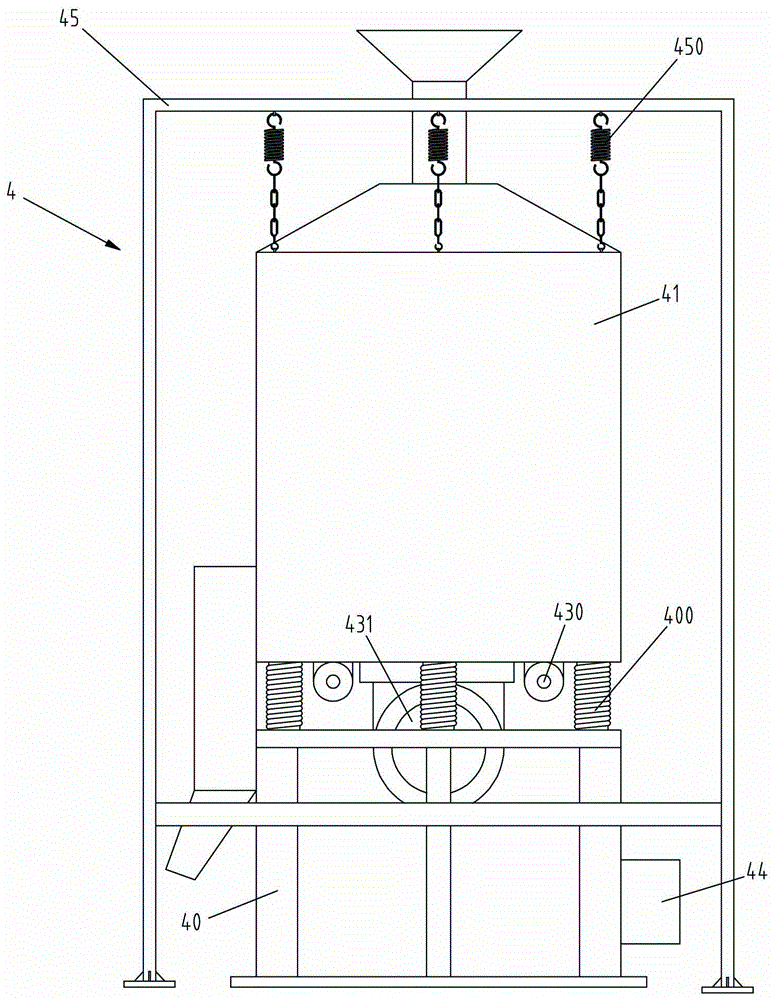

[0030] Reference figure 1 with figure 2 , The production equipment of fine tailings powder, the first crusher 13 for crushing raw materials is connected to the tailings silo 10, the tailings silo 10 is connected to the upstream end of the conveyor belt 12 via a belt weighing scale 11, the conveyor belt 12 The downstream end of the rotary dryer 20 is connected to the feed inlet of the rotary dryer 20, the rotary dryer 20 supplies heat 21 through the boiling furnace, the outlet of the rotary dryer 20 and the feed inlet of the magnetic separator 22 The outlet of the magnetic separator 22 is connected with a trommel 30, the trommel 30 is provided with a medium sand outlet and a fine material outlet, and the medium sand outlet is connected to the feed inlet of the second crusher 33 , The discharge port of the second crusher is connected to the feed port of the trommel 30; the fine material outlet is connected to a fine material stable silo 31, which is connected to a fine material m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com