Environmentally-friendly machine spray mortar, its production method and its use method

An environment-friendly, machine-sprayed mortar technology, applied in the field of building materials, can solve the problems of unpopularization of ready-mixed mortar machine-sprayed industrial construction, high price of powder materials, poor fluidity of ready-mixed mortar, etc., to achieve convenient continuous mechanized operation, The loss of work performance index is less, and the effect of promoting the development of circular economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

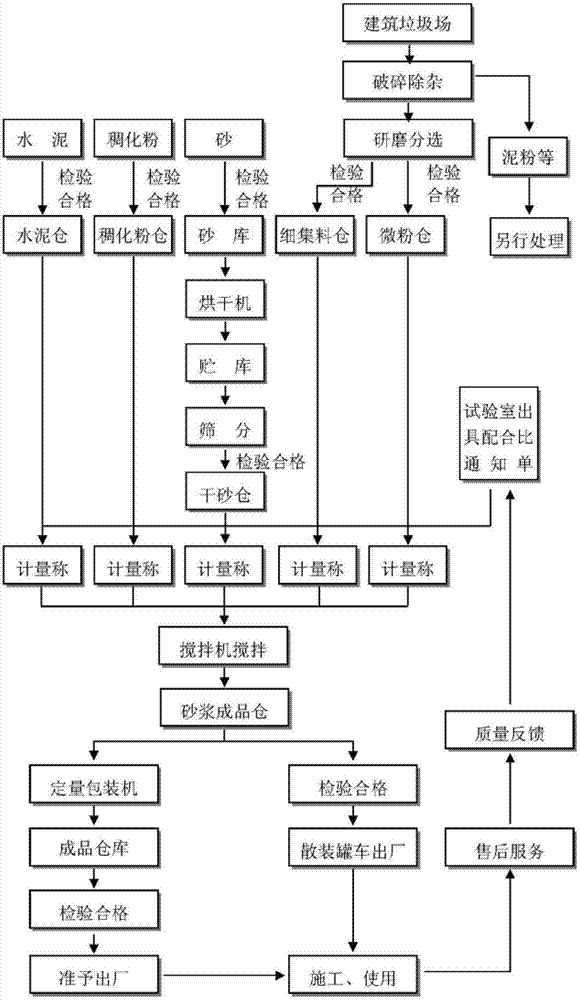

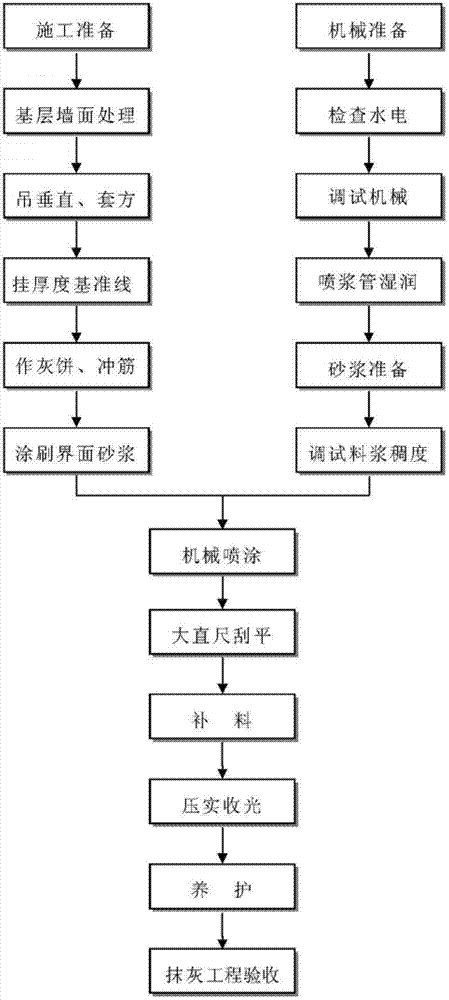

Method used

Image

Examples

Embodiment 1

[0044] Example 1 , Preparation of recycled powder

[0045] Prepare the regenerated powder of the present invention according to the following steps:

[0046] A. Dispose of construction waste through pretreatment equipment to obtain materials with a particle size of 5mm≤particle size≤50mm;

[0047] Specifically, the construction waste is first roughly crushed, and the construction waste is roughly crushed to a material with a particle size of about 100mm by using extrusion crushing equipment or impact crushing equipment; then light combustible materials such as plastics, fabrics, and wood in the construction waste are manually or mechanical sorting and removal; then use impact crushing equipment (impact crushing or coarse hammer crushing) to achieve medium crushing of construction waste coarse materials; at the same time, due to the low strength of the soil in construction waste, in the high-speed rotating crushing equipment , beating, grinding, rubbing and other processes, ...

Embodiment 2

[0050] Example 2 , Preparation of environment-friendly machine-sprayed plaster

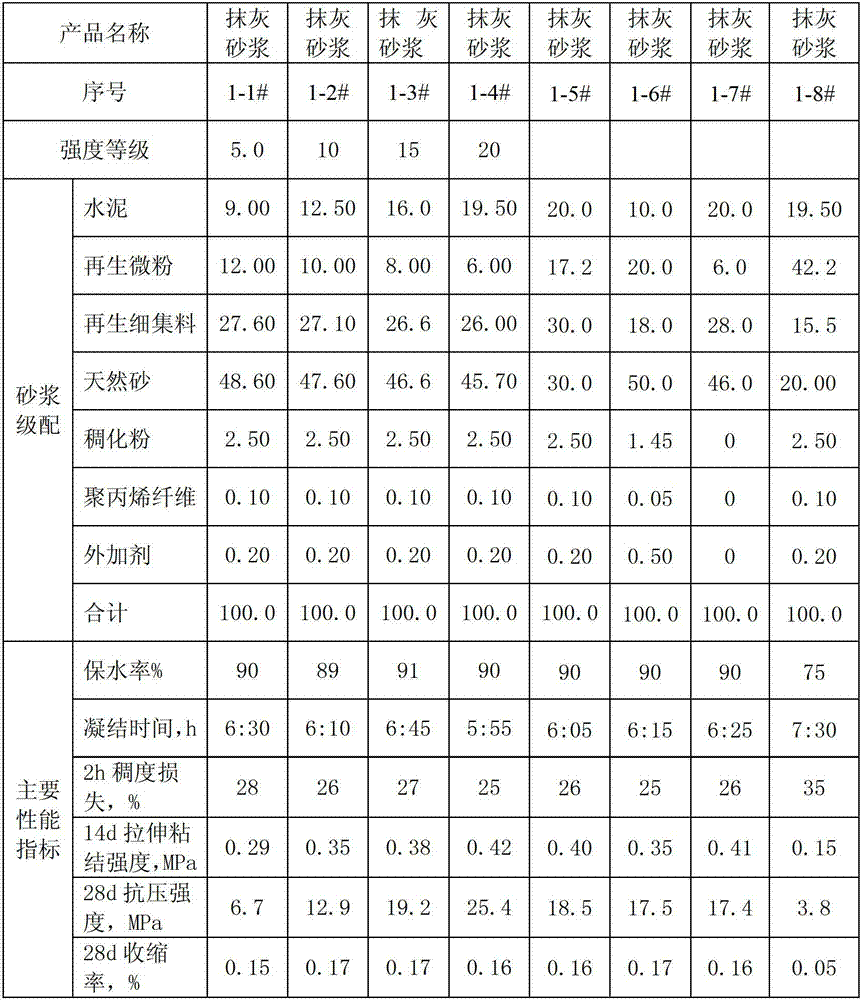

[0051] According to the formula shown in Table 1, the recycled micropowder is used as an admixture to produce mortar, and the components are mixed and stirred evenly according to the weight ratio (%) to obtain an environmentally friendly machine-blasted mortar. Regenerated micropowder can replace part of cement or all fly ash, and can produce environment-friendly machine sprayed plastering mortar with strength grades of M5, M10, M15 and M20.

[0052] Table 1 An environment-friendly machine-sprayed plastering mortar weight ratio (%)

[0053]

[0054] According to the above experimental data of the environment-friendly machine-sprayed plastering mortar, the environment-friendly machine-sprayed plastering mortar adopts 1-1#, 1-2#, 1-3#, 1-4#, 1-5 #, 1-6# and 1-7#, the 28d compressive strength reaches more than 127% of the requirement, the 14d tensile bond strength reaches more than 175% of the re...

Embodiment 3

[0056] Example 3 , Preparation of environment-friendly machine-sprayed desulfurization gypsum plaster mortar

[0057] According to the formula shown in Table 2, the recycled differential is used as an admixture to produce mortar, and each component is mixed and stirred evenly according to the weight ratio (%) to obtain an environmentally friendly machine-blasted mortar. Regenerated micropowder can replace part of cement or all fly ash, and can produce environment-friendly machine-sprayed desulfurization gypsum plaster mortar.

[0058] Table 2 An environment-friendly machine-sprayed desulfurization gypsum plaster mortar Weight ratio (%)

[0059]

[0060]

[0061] According to the above experimental data of the environment-friendly machine-sprayed desulfurization gypsum plaster mortar, the environment-friendly machine-sprayed desulfurization gypsum plaster mortar adopts the preparation of 2-1#, 2-2#, 2-3# and 2-4# The proportion and 3D compressive strength all reach mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com