A kind of artificial marble sawdust exterior wall flexible putty

A technology of artificial marble and sawdust, which is applied in the field of flexible putty for exterior walls of artificial marble sawdust, can solve the problems of loss of decorative and protective functions of the coating, affect the normal use of buildings, and poor performance, so as to improve flexibility and water resistance, Excellent two-way affinity and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

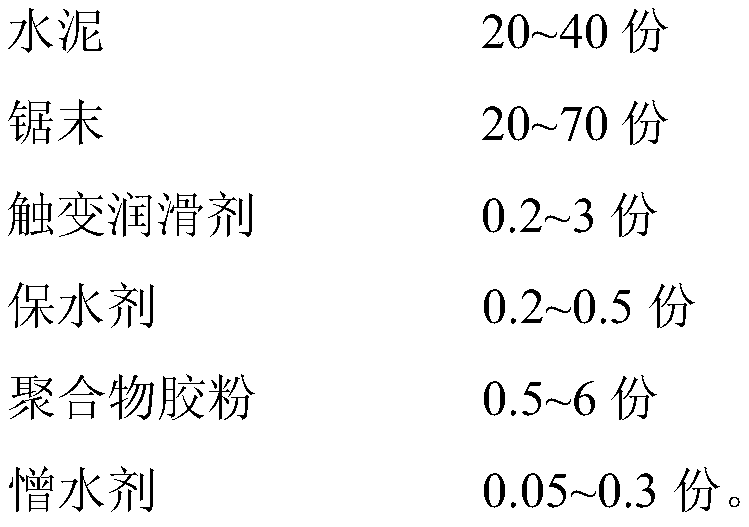

[0025] A kind of artificial marble sawdust exterior wall flexible putty, its composition is by mass parts:

[0026]

[0027] Wherein the cement is Portland cement; the sawdust is sawdust produced during the cutting of organic polymer artificial marble, the maximum particle size is <80 mesh, and the moisture content is ≤0.2%; the thixotropic lubricant is sodium-based bentonite; the water-retaining agent is hydroxyethyl methyl cellulose ether; the polymer powder is vinyl acetate and ethylene copolymer latex powder, with a solid content of ≥98% and a fineness of 0.5-8 μm; the hydrophobic The water agent is a silicone water repellent.

[0028] Stir the above raw materials evenly, add water and stir until it becomes a paste, and then the marble sawdust exterior wall flexible putty is prepared; the bonding strength with the mortar is as high as 0.9MPa, the diameter is 50mm without cracks, and the performance meets the requirements of GB / T 23455-2009.

Embodiment 2

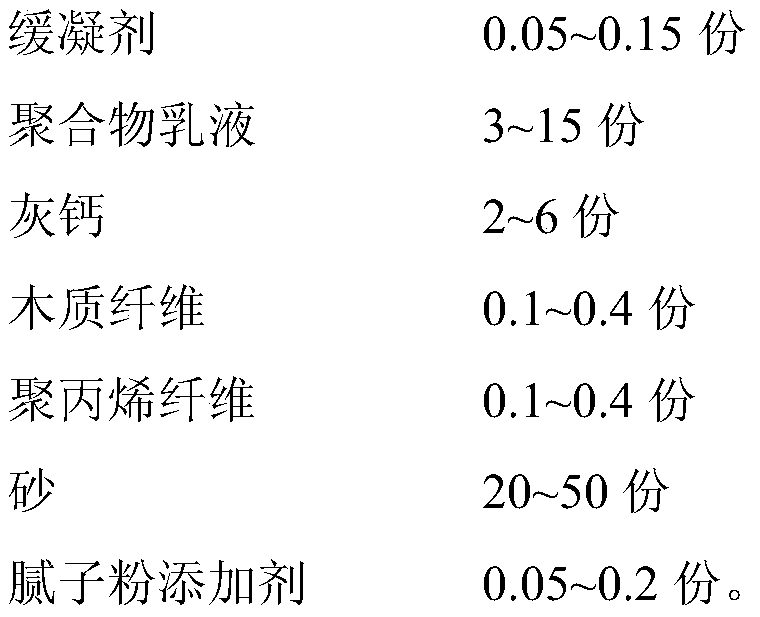

[0030] A kind of artificial marble sawdust exterior wall flexible putty, its composition is by mass parts:

[0031]

[0032] Wherein the cement is white Portland cement; the sawdust is sawdust produced during the cutting of organic polymer artificial marble, the maximum particle size is <80 mesh, and the water content is ≤0.2%; the thixotropic lubricant is sodium A mixture of base bentonite and metakaolin; the water-retaining agent is hydroxypropyl methylcellulose ether; the polymer powder is vinyl acetate and ethylene copolymer latex powder, with a solid content of ≥98% and a fineness of 0.5- 8 μm; the described hydrophobic agent is a calcium stearate hydrophobic agent; the described retarder is a mixture of tartaric acid and sodium citrate; the described polymer emulsion is an acrylic acid emulsion; calcium hydroxide in the described ash calcium The mass percentage of ≥ 90%, the maximum particle size < 80 mesh; the length of the wood fiber < 1mm, the ash content < 12%; th...

Embodiment 3

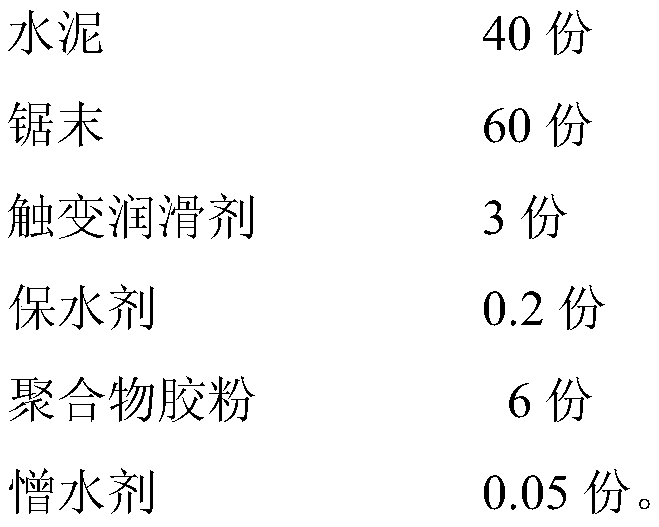

[0035] A kind of artificial marble sawdust exterior wall flexible putty, its composition is by mass parts:

[0036]

[0037] Wherein the cement is white Portland cement; the sawdust is sawdust produced during the cutting of organic polymer artificial marble, the maximum particle size is <80 mesh, and the water content is ≤0.2%; the thixotropic lubricant is sodium A mixture of base bentonite and metakaolin; the water-retaining agent is hydroxypropyl methylcellulose ether; the polymer powder is vinyl acetate and ethylene copolymer latex powder, with a solid content of ≥98% and a fineness of 0.5- 8 μm; the water-repellent agent is a silicone water-repellent agent; the mass percentage of calcium hydroxide in the ash calcium is ≥90%, the maximum particle size is <80 mesh; the length of the wood fiber is <1 mm, and the ash content is <12% The length of the polypropylene fiber is 3-6 mm; the sand is 70-140 mesh dry sand; the putty powder additive is a commercially available putty ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com