Quick-hardening anti-cracking cement-based self-leveling mortar powder, slurry, mortar and preparation method thereof

A self-leveling mortar and cement-based technology, which is applied in the field of mortar and preparation, rapid hardening and anti-cracking cement-based self-leveling mortar powder, and slurry, can solve the problems of unstable quality of self-leveling mortar, low tensile bonding strength, volume Poor stability and other problems, to achieve the effect of improving tool turnover efficiency, improving mechanical properties, quality and performance fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In a second aspect, the present invention provides a method for preparing rapid-hardening and anti-cracking cement-based self-leveling mortar powder, comprising the following steps: mixing fast-setting rapid-hardening high-Belite sulphoaluminate cement and / or white fast-setting fast Hard high belite sulfoaluminate cement is mixed with fine aggregate, water reducer, defoamer, latex powder, retarder and coagulant to obtain the described rapid hardening and anti-cracking cement-based self-leveling mortar powder .

[0061] In a third aspect, the present invention provides a rapid-hardening and anti-cracking cement-based self-leveling mortar, including water and the rapid-hardening and anti-cracking cement-based self-leveling mortar powder of the present invention, wherein the weight ratio of water to powder is 0.14~ 0.28.

[0062] In the present invention, the fast-setting rapid-hardening high-Belite sulfoaluminate cement is the only cementitious material. The cement has e...

Embodiment 1~9

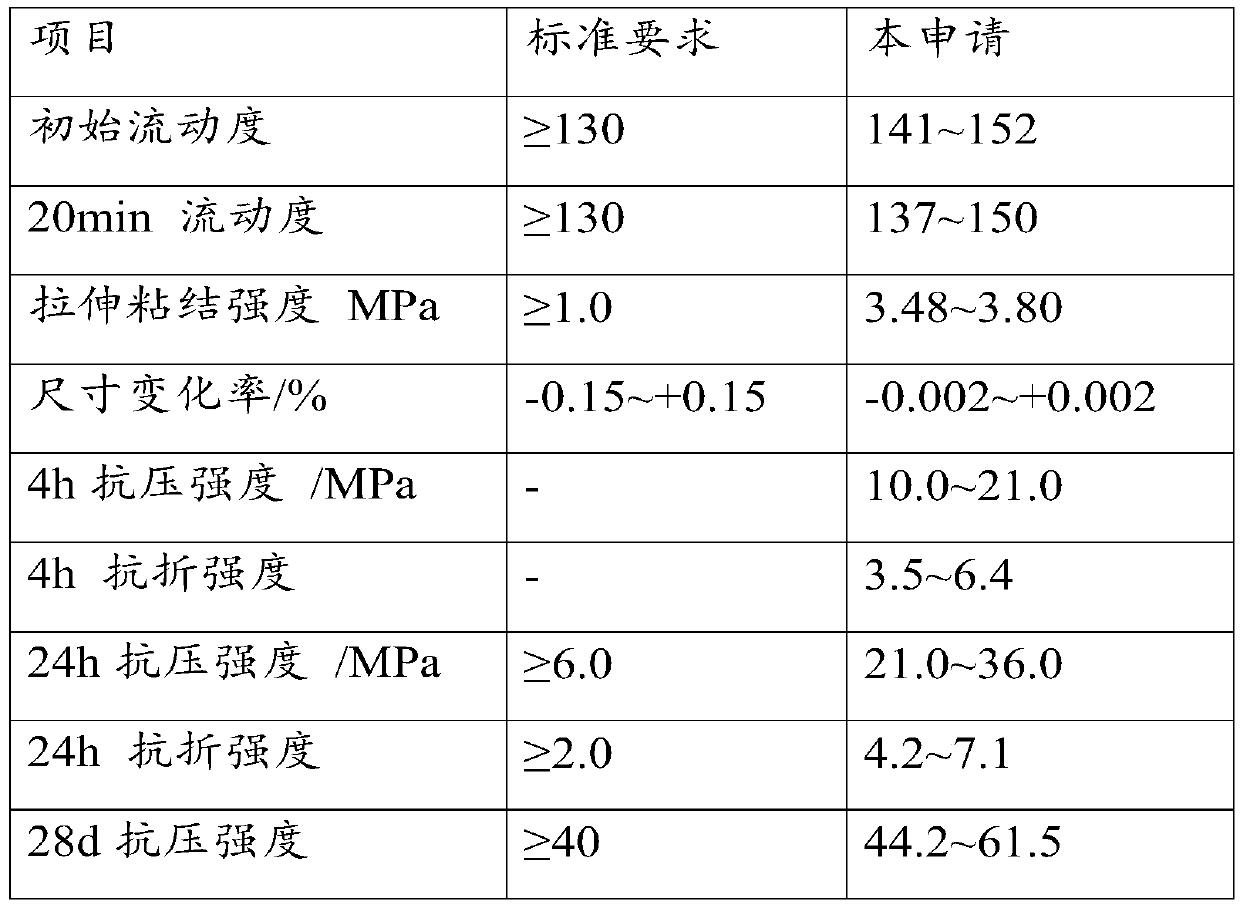

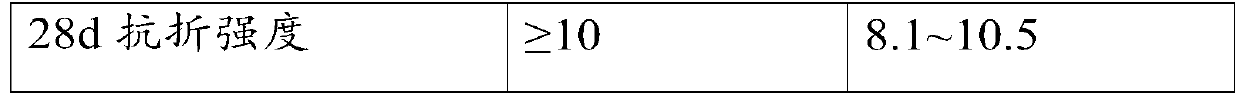

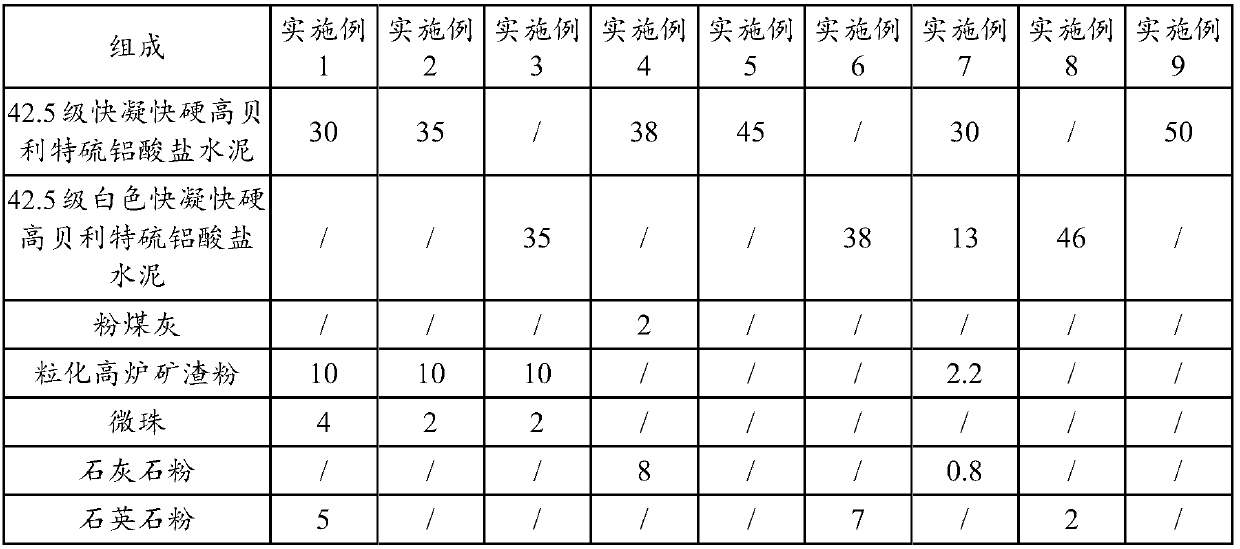

[0069] Examples 1 to 9 are respectively a kind of rapid-hardening and anti-cracking cement-based self-leveling mortar, wherein the raw material ratio of the mortar powder in terms of weight percentage is shown in Table 1. The preparation method of the rapid-hardening anti-cracking cement-based self-leveling mortar in Examples 1 to 9 is as follows: the fast-setting rapid-hardening high-Belite sulfoaluminate cement or white fast-setting rapid-hardening high-Belite sulfoaluminate cement , mineral admixture, fine aggregate, water reducer, defoamer, latex powder, retarder, coagulant and water are mixed together to obtain the rapid hardening and anti-cracking cement-based self-leveling mortar.

[0070] Table 1 Raw material ratio of the rapid hardening and anti-cracking cement-based self-leveling mortar powder in Examples 1 to 9

[0071]

[0072]

[0073] The fine aggregate, water reducer, thickener, defoamer, latex powder, retarder and coagulant used in Examples 1-9 are all th...

Embodiment 10

[0078] Compared with Example 9, the difference is that the fine aggregate used in the rapid hardening and anti-cracking cement-based self-leveling mortar in this example is 80-120 mesh white quartz sand. Other raw material types and components are all the same as in Example 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com