Patents

Literature

75results about How to "Play a retarding role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

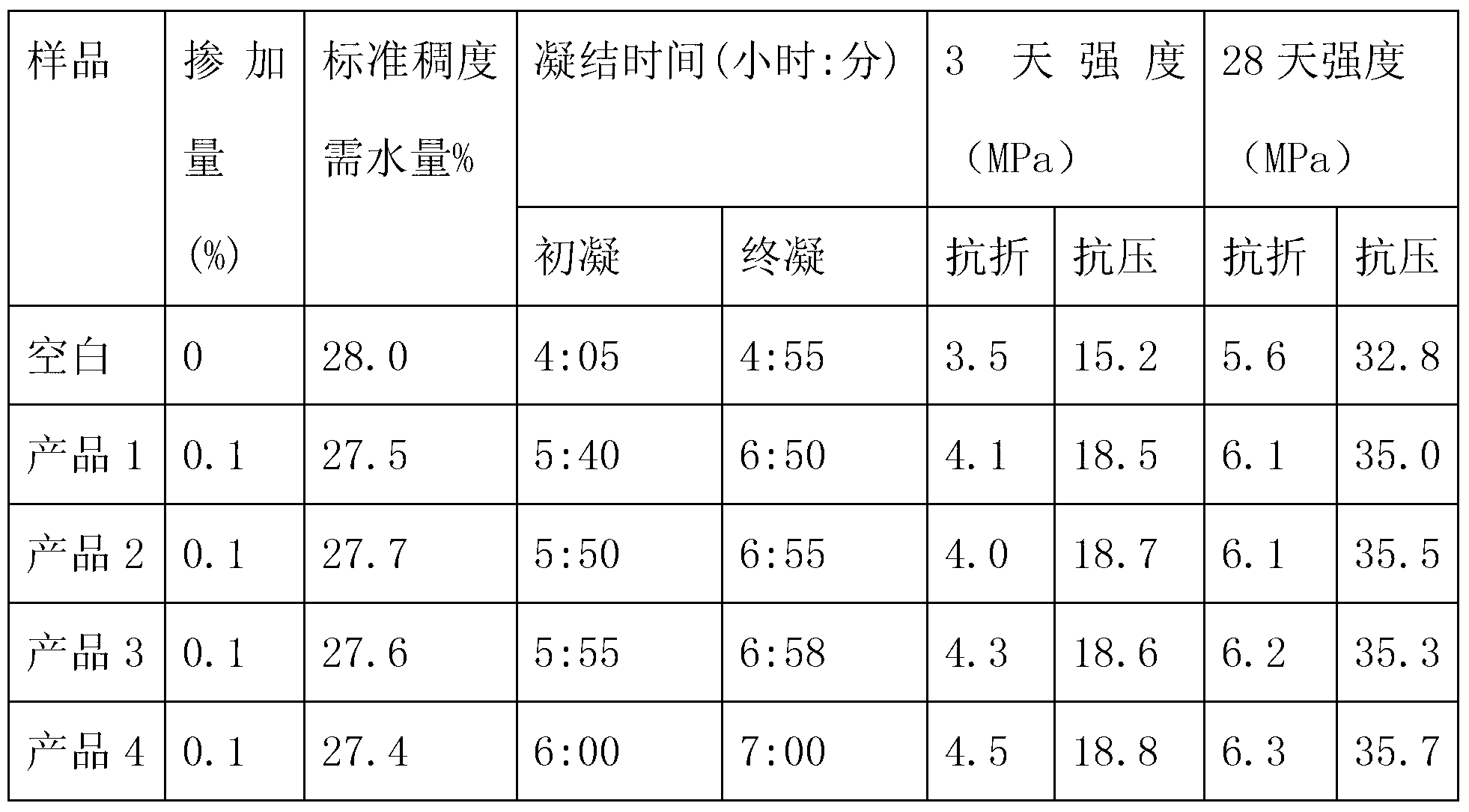

Retarded cement grinding aid and preparation method thereof

ActiveCN103193415AImprove early strengthIncrease late strengthCarboxymethyl celluloseCement grinding

The invention discloses a retarded cement grinding aid and a preparation method thereof. The retarded cement grinding aid comprises 0.01-0.02wt% of sodium carboxymethyl cellulose, 25-30wt% of molasses calcium, 5-10wt% of citric acid and the balance of water, wherein the total percent is 100%. The retarded cement grinding aid provided by the invention has the beneficial effects that the molasses calcium is used instead of the molasses and cane sugar commonly used at present, is a powdery product prepared by neutralizing the molasses with lime, has better water reducing and retarding effects than the molasses and saves the cost; and the hydration and hardening time of the cement is effectively lengthened so that the freshly mixed cement concrete can maintain the plasticity in a longer time, thus adjusting the setting time of the freshly mixed cement concrete.

Owner:NANJING YONGNENG MATERIALS

Extinguishment composition, purpose of extinguishment composition and extinguishment method

InactiveCN104001298AEasy to transportMeet the requirements of fire extinguishing grouting materialsDust removalFire preventionSpontaneous combustionSlurry

The invention discloses an extinguishment composition. The extinguishment composition comprises extinguishment powder and water, wherein the weight ratio of the extinguishment powder to the water ranges from 1:0.8 to 1:1.2. The extinguishment powder is composed of, by weight, 3 parts to 7 parts of calcium silicon residues, 1 part to 3 parts of fly ash, 1 part to 3 parts of flue gas desulfurization gypsum, and 0.5 part to 1.5 parts of cement. The invention further discloses an extinguishment method for spontaneous combustion of coal in a goaf. The method includes the first step of mixing and stirring the extinguishment powder with the water according to the weight ratio ranging from 1:0.8 to 1:1.2 to form extinguishment slurry, and the second step of injecting or spraying the extinguishment slurry manufactured in the first step into the goaf with the requirement for extinguishment so as to conduct grouting extinguishment. The invention further provides the purpose of using the extinguishment composition for conducting extinguishment for spontaneous combustion of the coal in the goaf. According to the method, less clay or loess is used, workloads for processing the extinguishment slurry are reduced, and acid gas produced by coal combustion can be solidified.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

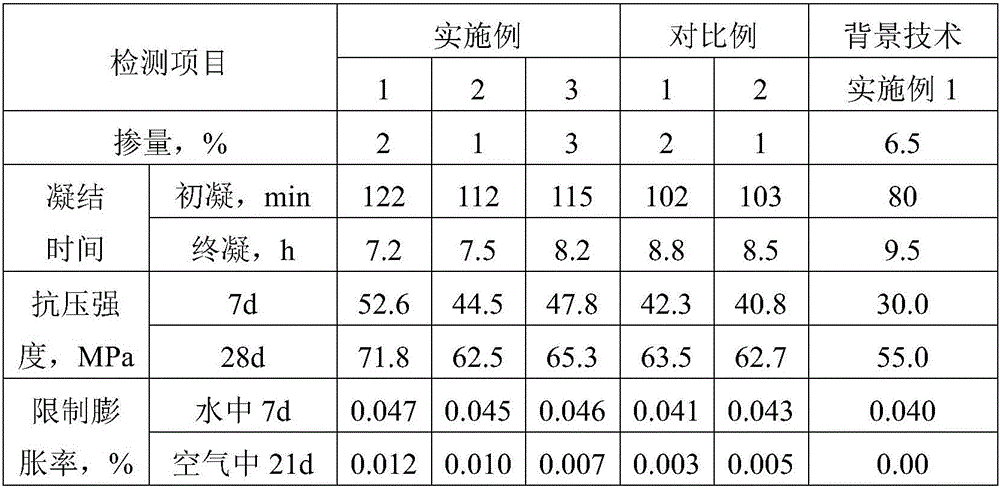

Compound concrete expanding agent

The invention discloses a compound concrete expanding agent. The compound concrete expanding agent is prepared by using the following components in parts by weight: 15 to 20 parts of calcium aluminosilicate, 25 to 30 parts of calcium sulphoaluminate, 20 to 30 parts of sulfur fixation waste residue, 10 to 20 parts of red mud, 10 to 15 parts of lithium slag, 4 to 8 parts of modified calcium oxide, 3 to 6 parts of magnesium oxide, 5 to 8 parts of methyl sodium silicate, 0.1 to 0.3 part of azodicarbonamide, 0.4 to 0.7 part of sodium tripolyphosphate, 2 to 4 parts of lauryl sodium sulfate, 0.3 to 0.6 part of ethylene-acrylic acid copolymer, 0.7 to 0.9 part of polycarboxylate superplasticizer and 0.5 to 0.7 part of nano calcium carbonate. The compound concrete expanding agent has the advantages of high strength, good compensation capability, calcium oxide reaction regulation and the like, and is a concrete additive which has a great development prospect.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

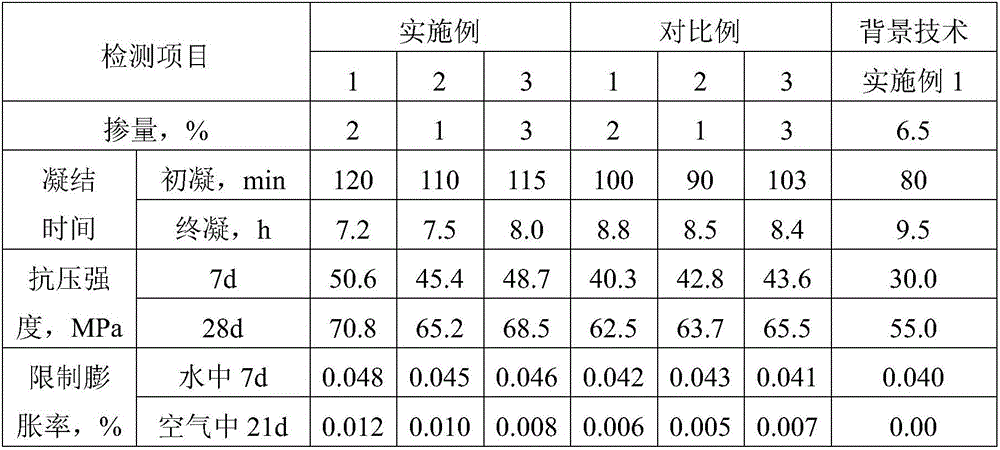

Concrete expanding agent

The invention discloses a concrete expanding agent. The concrete expanding agent is prepared from, by weight, 10-15 parts of calcium silicoaluminate, 20-30 parts of calcium sulphoaluminate, 5-9 parts of ferric sulfate, 20-25 parts of sulfur-fixing waste residues, 15-20 parts of red mud, 6-8 parts of modified calcium oxide, 4-6 parts of magnesium oxide, 4-8 parts of sodium methyl silicate, 3-5 parts of triethanolamine, 0.1-0.3 part of azodicarbonamide, 0.5-0.7 part of sodium gluconate, 2-4 parts of sodium laurylsulfate, 0.4-0.6 part of polyethylene glycol, 1-3 parts of polycarboxylate superplasticizer, 2-6 parts of modified pyrophillite powder and 1-3 parts of nano calcium carbonate. The concrete expanding agent has the advantages of being high in strength, good in compensation capability, capable of regulating and controlling a calcium oxide reaction and the like and is a concrete additive having the development prospect.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

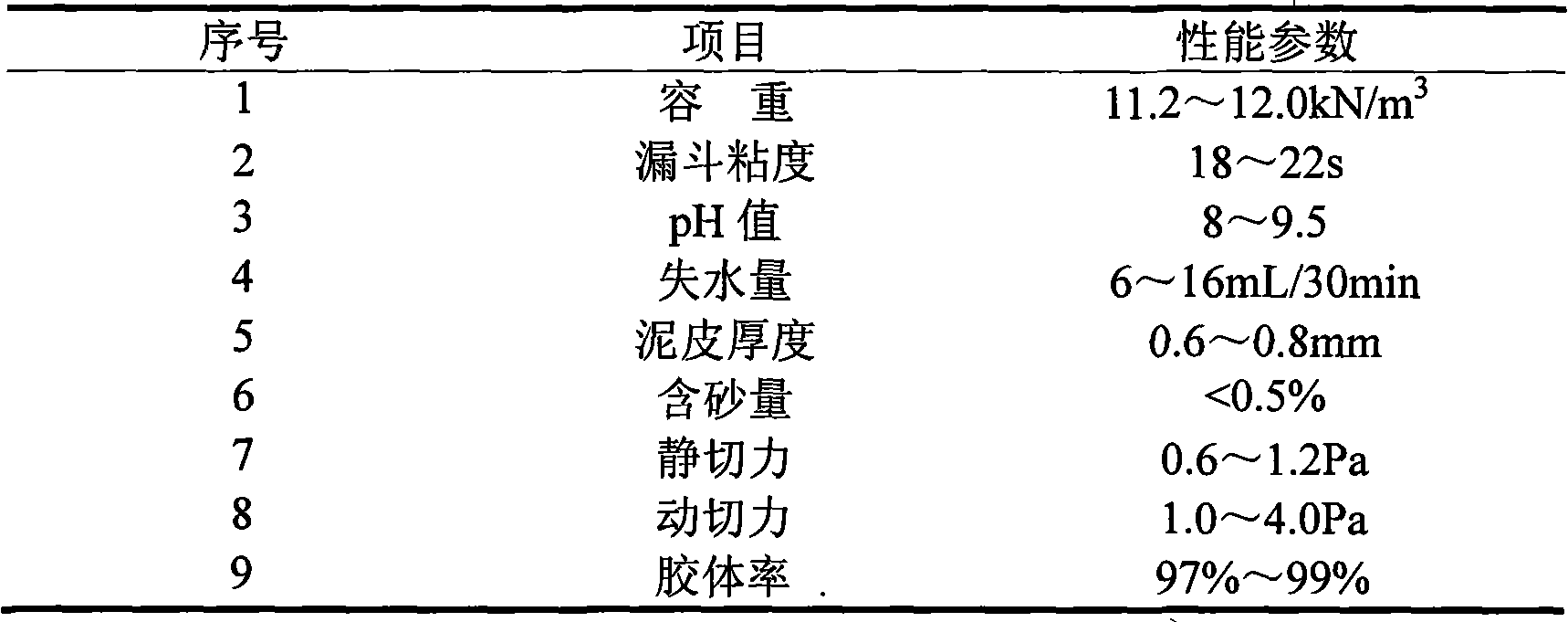

Working slurry of stop-grouting plug for mine ground pre-grouting

ActiveCN101665683ASimple configurationImprove performanceDrilling compositionCarboxymethyl celluloseDifferential pressure

The invention relates to working slurry of a stop-grouting plug for mine ground pre-grouting, comprising the following components in portions by weight: 881-912 portions of water, 200-300 portions ofbentonite, 3-4.5 portions of calcined soda, 0.1 portion of sodium carboxymethyl cellulose, 1.0-2.5 portions of potassium humate and 0.75-1.85 portions of sucrose. The invention is used in the field ofground pre-grouting, and can effectively reduce the accident probability of the stop-grouting plug in a working state, such as fracture plug burial, channeling slurry plug burial, differential pressure sticking, and the like, ensure the safety and the high efficiency of the grouting and the mine construction and have the favorable application prospect.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Ceramic tile bonding mortar

The invention discloses a ceramic tile bonding mortar. The ceramic tile bonding mortar is composed of a base material and an additive; the base material comprises, by weight, 350 to 410 parts of ordinary portland cement, 530 to 600 parts of sand with a particle size of 40 to 100 meshes, and 45 to 5 parts of heavy calcium carbonate powder; and the additive comprises, 2 to 3 parts of high-molecular xanthan gum powder, 1.5 to 2 parts of hydroxypropyl methyl cellulose, and 0 to 5 parts of redispersible latex powder. According to the ceramic tile bonding mortar, adding of high-molecular xanthan gum powder and hydroxypropyl methyl cellulose is capable of increasing viscosity of the ceramic tile bonding mortar greatly; water holding effect is excellent; delayed coagulation is realized; operation time of operators is prolonged; the ceramic tile bonding mortar is suitable for long-distance transportation; strength after hardening is high; ceramic tile loosening or falling after bonding is avoided; adding of redispersible latex powder is capable of improving water resistance of the ceramic tile bonding mortar; and construction under moisture circumstances can be carried out.

Owner:许勤峰

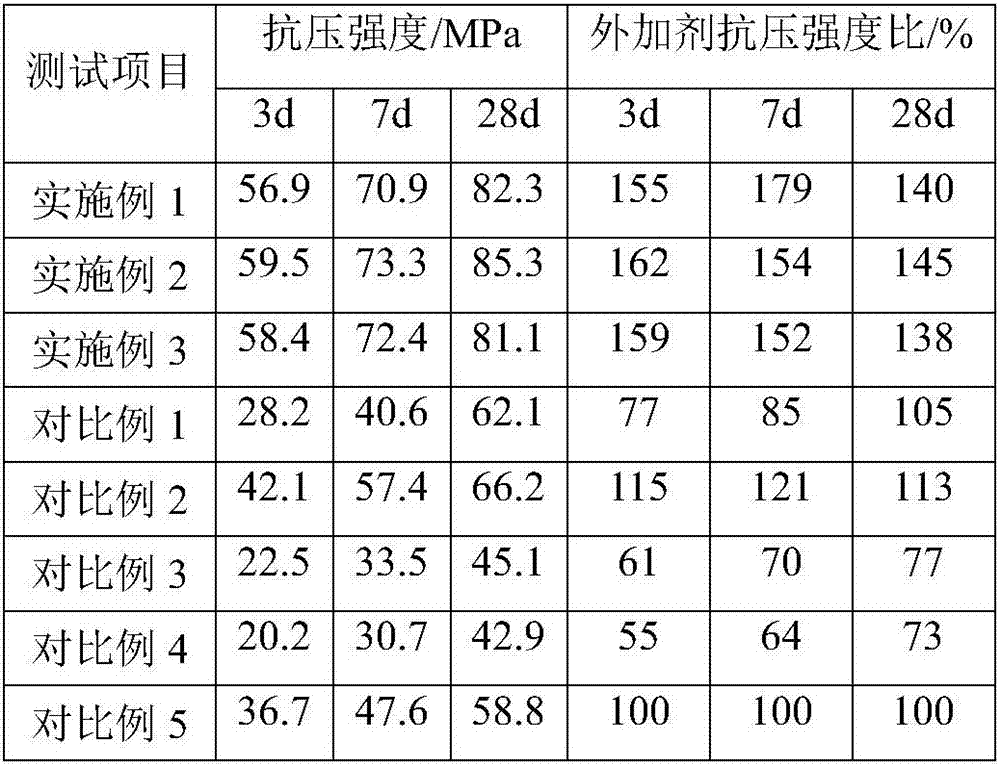

Concrete early-strength agent and preparation method thereof

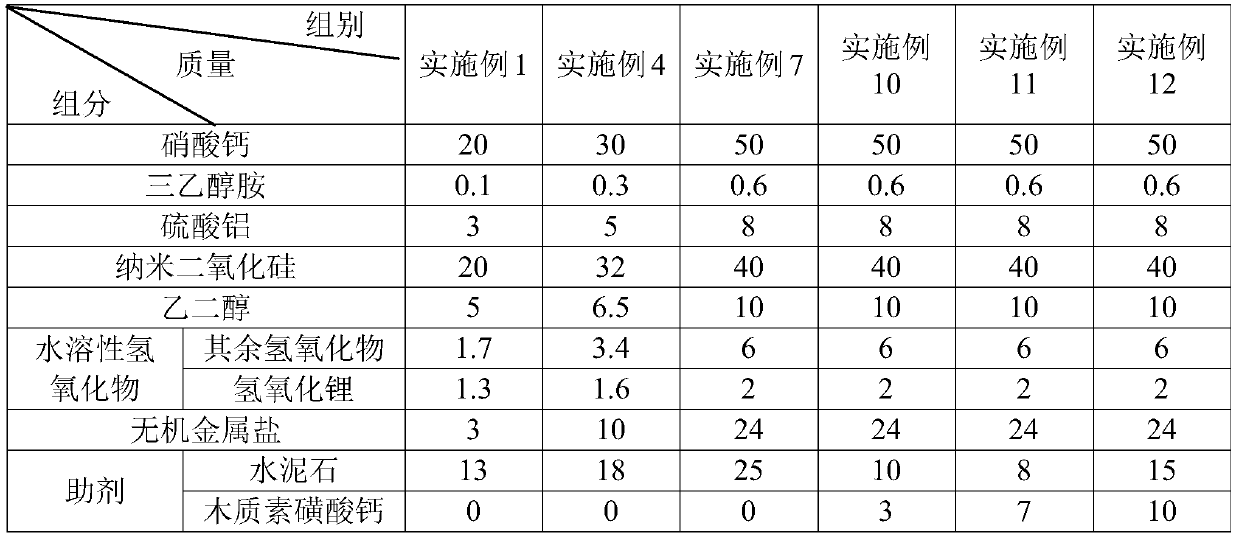

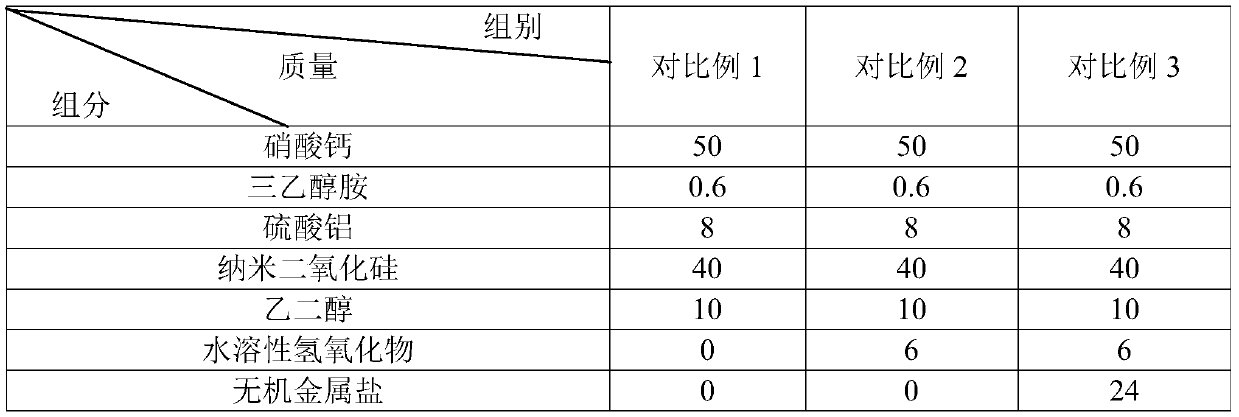

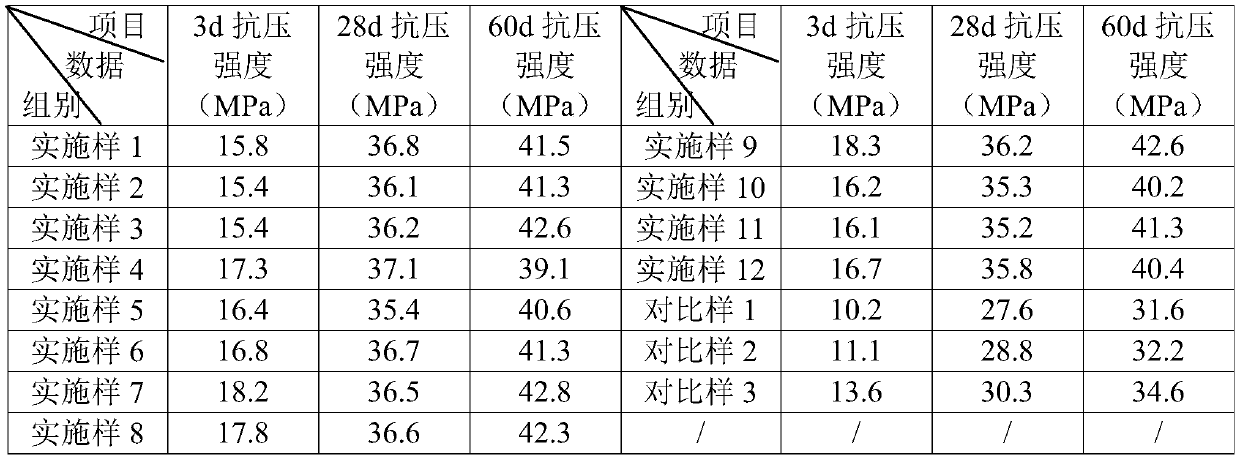

The invention discloses a concrete early strength agent and a preparation method thereof, belongs to the field of concrete admixtures, and solves the problem that an early strength agent in a low-temperature environment is not obvious in concrete early strength effect. The concrete early strength agent comprises the following components in parts by weight: 20-50 parts of calcium nitrate, 0.1-0.6 part of triethanolamine, 3-8 parts of aluminum sulfate, 20-40 parts of nano silicon dioxide, 5-10 parts of ethylene glycol and 3-8 parts of water-soluble hydroxide. The weight part ratio of the inorganic metal salt to the water-soluble hydroxide is (1-3):1; the water-soluble hydroxide contains 1.3-2 parts of lithium hydroxide; metal cations in the inorganic metal salt are a combination of first ions and magnesium ions or magnesium ions, the first ions being one of ferric ions, ferrous ions and aluminum ions. When the early strength agent is used in a low-temperature environment, a good early strength effect can be achieved.

Owner:广东浩枫建设有限公司

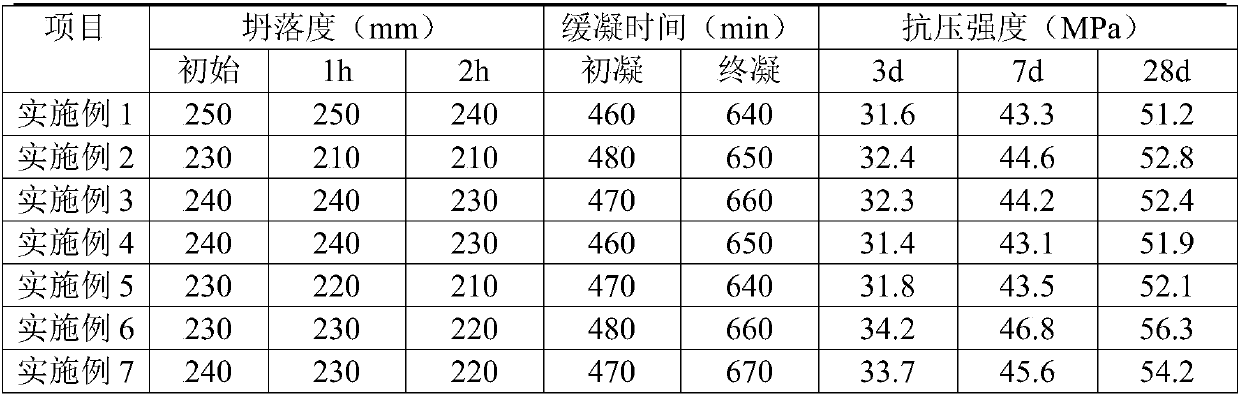

Super-retarded concrete

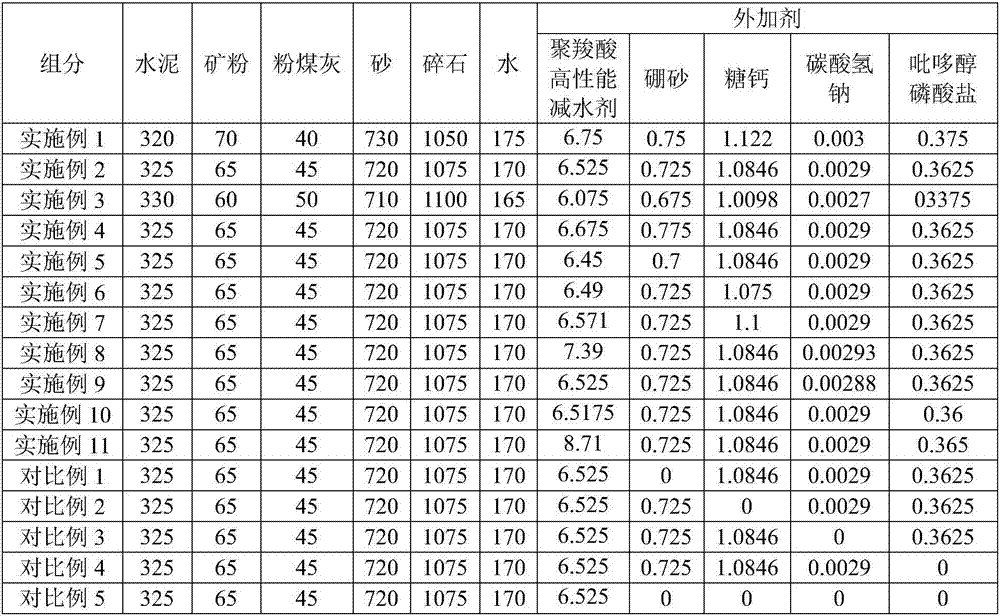

The invention relates to super-retarded concrete, which is characterized by comprising the following raw materials (by weight): 320-330 parts of cement, 60-70 parts of mineral powder, 40-50 parts of fly ash, 710-730 parts of sand, 1050-1100 parts of broken stone, 165-175 parts of water and 8.1-9 parts of an additive. The super-retarded concrete has long setting time and enough later strength.

Owner:天津金隅混凝土有限公司

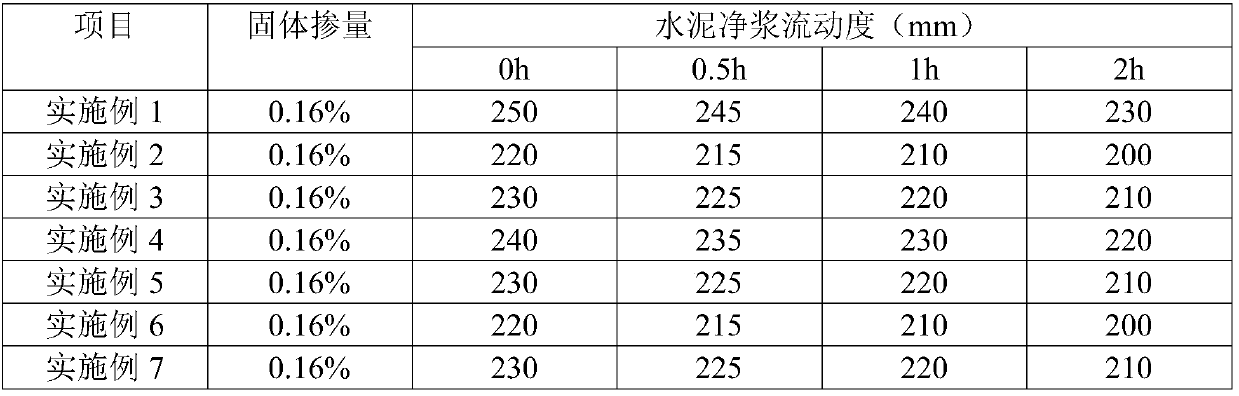

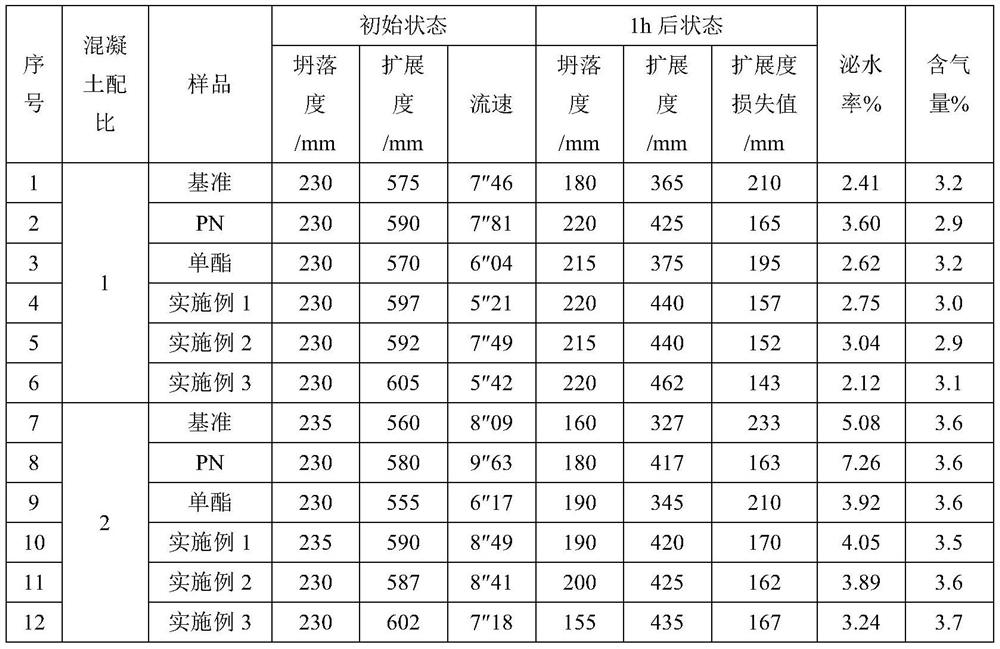

High-performance compound polycarboxylate superplasticizer

The invention provides a high-performance compound polycarboxylate superplasticizer and belongs to the technical field of superplasticizers. The high-performance compound polycarboxylate superplasticizer is prepared from components in parts by weight as follows: 10-20 parts of a polycarboxylate superplasticizer, 1-4 parts of methacrylate, 2-3 parts of tertiary carbonic ester, 0.2-0.3 parts of N-oleoylsarcosine, 2-4 parts of hydroxypropyl starch ether, 1-3 parts of glycerin, 1-3 parts of sodium dodecyl benzene sulfonate and 15-25 parts of water. The high-performance compound polycarboxylate superplasticizer is a compound superplasticizer and has excellent water reducing performance, slump loss resistant property, dispersity and workability.

Owner:河北合众建材有限公司

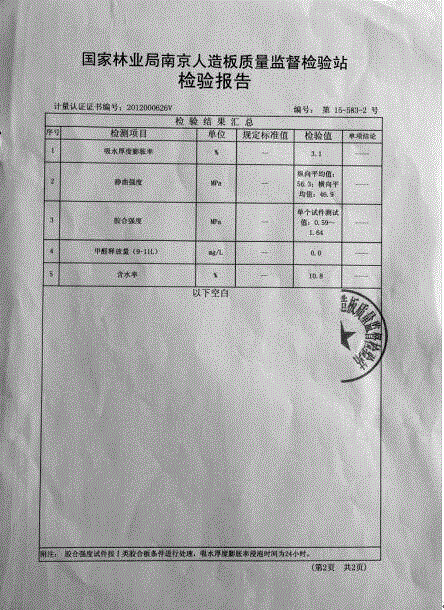

Gelatinizer

The invention relates to a gelatinizer including the following components, by weight: 30-350 parts of magnesium- and aluminum-rich silicate (Mg5Si8O20(OH)2(OH2)4.4H2O), 80-150 parts of high-activity aluminum silicate, 5-15 parts of boric acid (H3BO3), 5-15 parts of citric acid (C6H8O7), 2-15 parts of phosphoric acid (H3PO4), 5-10 parts of silicon sol (SiO2.nH2O), 1-3 parts of a siloxane waterproof agent, 800-1200 parts of light calcined magnesium oxide, 300-500 parts of magnesium chloride hexahydrate, 80-120 parts of magnesium sulfate heptahydrate, and 400-600 parts of water. The gelatinizer, on the basis of maintaining the technical indices, such as fireproof performance, waterproof performance and the like, is free of formaldehyde when being used for cementing and adhering various building decorative materials, so that the gelatinizer increases utilization rate of house, provides a green and environment-friendly living environment, and is beneficial to body health of residents.

Owner:上海禾鹤新材料科技有限公司

Retardant preparation method

InactiveCN102923987APlay a retarding roleDelay the rate of hydration hardeningAluminium hydroxidePhosphate

The invention discloses a retardant preparation method. The method is characterized in that by weight percent in the total weight, 25-85 percent of water, 20-30 percent of aluminium hydroxide, 10-20 percent of tartaric acid and 25-35 percent of phosphate are adopted as raw materials. According to the method, after being added in magnesite slurry, the retardant is reacted with Mg<2+> of the slurry to generate sparingly soluble salts which are coated on the surface and can prohibit the Mg2 from being in contact with water molecules, thereby playing a role of delaying coagulation; the more the retardant is added, the larger the cover degree is and the more obvious the coagulation delaying effect is. Besides, water molecules can permeate the MgO coated by the retardant through diffusion, so as to generate an osmotic pressure; and when the pressure reaches a certain extent, the cover layer is broken, the MgO is further hydrated, and the hydration and rigidification speed is slower.

Owner:杨益

Prepn of retardant for magnesite binding material

The retarding agent of magnesite cementing material is made up by using (wt%) water 25-35%, aluminium hydroxide 20-30%, tartaric acid 10-20% and phosphoric acid 25-35%. It can effectively delay initial setting time of slurry material, and can raise water-proof property of product.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Polymeric amino acid gypsum retarder

The invention discloses a polymeric amino acid gypsum retarder. The polymeric amino acid gypsum retarder is prepared from the following components in percentage by mass: 70-95% of polymerized amino acid and 5-30% of an excitant. The preparation method comprises the following steps: amino acid monomers containing carboxyl and amide groups are adopted for obtaining polymerization amino acid througha solid-phase polymerization method, then an alkali metal hydroxide is added for a reaction, and the obtained material is dried and crushed to obtain the polymeric amino acid gypsum retarder. The polymeric amino acid gypsum retarder prepared by the preparation method disclosed by the invention is non-toxic and harmless to the environment, does not generate any pollution, and has little negative influence on the strength of gypsum.

Owner:北京博润佳科技有限公司

Tile gap filling mortar

A tile gap filling mortar comprises a base material and an additive, and the base material comprises, by weight, 370-420 parts of ordinary Portland cement, 520-580 parts of sand and 40-50 parts of heavy calcium powder; and the additive comprises, by weight, 2-3 parts of high-molecular xanthan gum powder, 0.25-0.75 parts of hydroxypropyl methyl cellulose, 5-10 parts of re-dispersible latex powder, 1-2 parts of a water repellent, 1-3 parts of glass water and 1-5 parts of a water reducer. The increase of the additive improves the water retention and the bonding force of the mortar, reduces the shrinkage of the mortar and increases the ageing resistance of the mortar, so the mortar can effectively fill gaps between tiles, and slit cracking is avoided. The addition of the water glass makes the adhesion stress and the acid and alkali resistance of the mortar enhanced. The addition of the water repellent enhances the corrosion resistance of the gap filling mortar to make a permanent waterproof film formed.

Owner:许勤峰

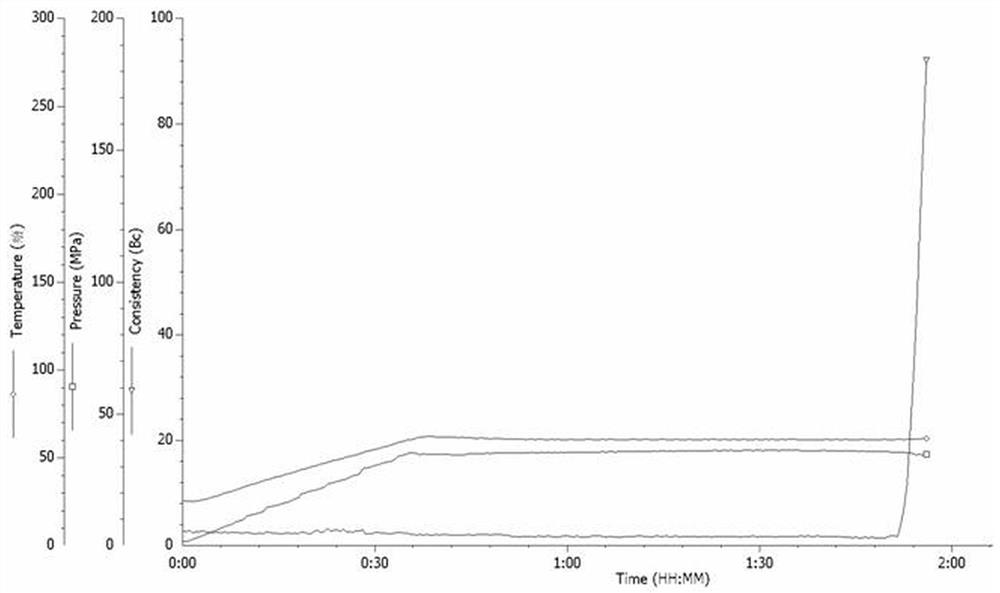

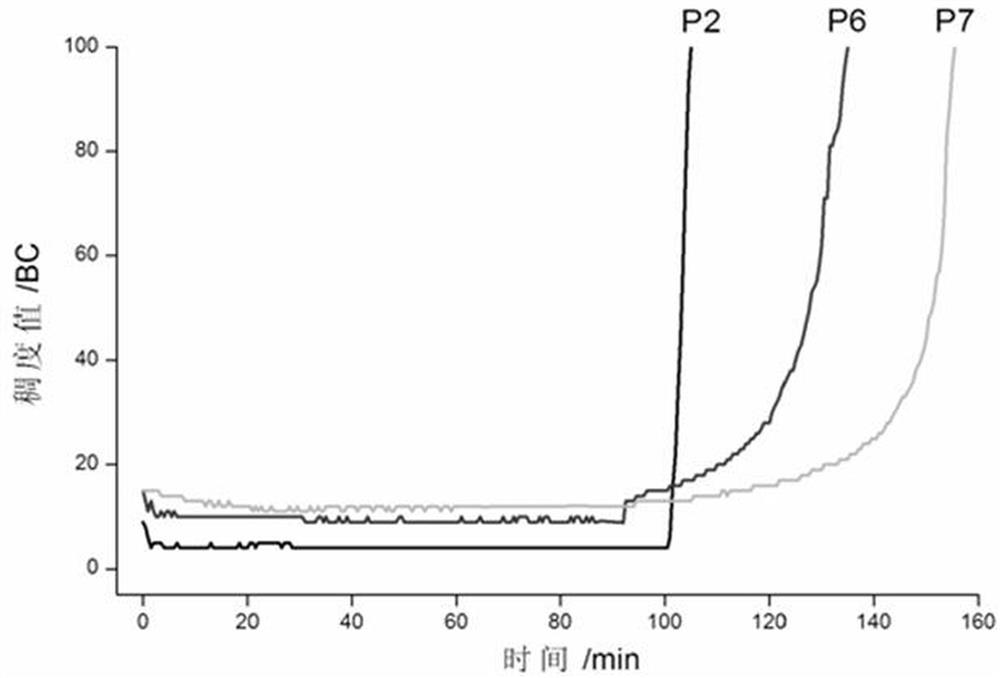

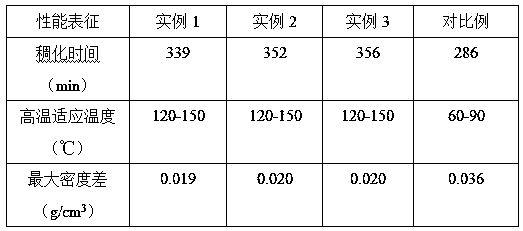

Cement paste system for long-cementing-section large-temperature-difference cementing

ActiveCN112961658ASatisfy retardationWide use temperature rangeDrilling compositionMeth-Ethylenediaminetetra(methylenephosphonic)acid

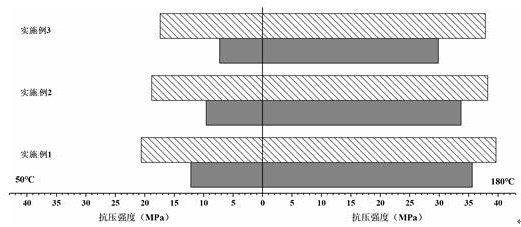

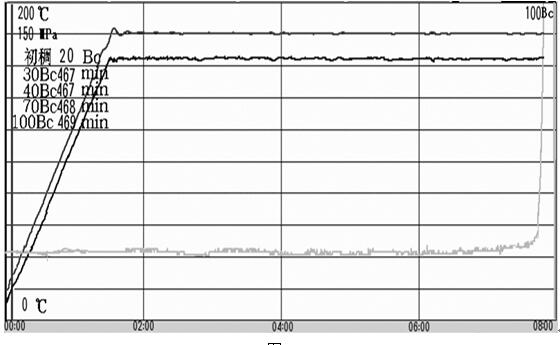

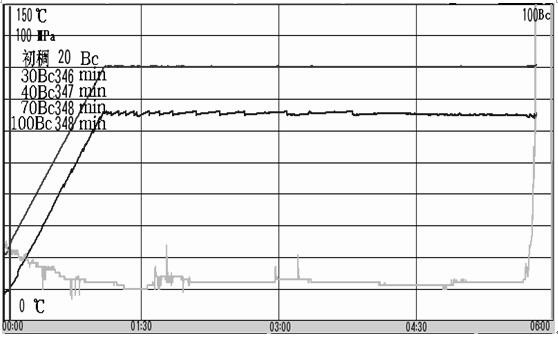

The invention discloses a cement slurry system for long-cementing-section large-temperature-difference cementing, and relates to the technical field of oil and gas field cementing materials. The cement paste consists of 74-88 wt% of oil well cement, 4-8 wt% of a fluid loss agent, 1-3 wt% of a suspension stabilizer, 10-20 wt% of a high-temperature strength stabilizer and 1-3 wt% of a retarder. The retarder is formed by mixing and compounding sodium ethylene diamine tetramethylene phosphonate, borax and a ternary polymer. The ternary polymer is prepared by taking sodium methallyl sulfonate, isopentenol polyvinyl ether and maleic anhydride as monomers and adopting a free radical solution copolymerization method. The cement paste provided by the invention has a wide use temperature interval, can meet the retarding effect on cement paste in the whole temperature interval that the temperatures of the upper end and the lower end of a cement paste injection well section in cementing construction are 50 DEG C and 180 DEG C respectively, the cement paste is ensured to have certain strength in a 50-DEG C high-temperature large-temperature-difference environment at the top, and the super retarding phenomenon of top cement is avoided.

Owner:JIAHUA SPECIAL CEMENT

Silt compounded curing agent

InactiveCN106365539AAdjust delay timeAct as surface activeSoil preservationDynamic compactionAdhesive

The invention relates to a curing agent, in particular to a silt compounded curing agent which is prepared from the following components in parts by mass: 20-50 parts of an inorganic material adhesive, 2-5 parts of an activator and 2-10 parts of an organic matter surfactant. The silt compounded curing agent is mainly acted on silt, can replace the traditional construction process of vacuum preloading, rockery skin changing and filling and dynamic compaction and can be used for foundation treatment of expressways, municipal roads, storage yards and various building places.

Owner:天津恒吉生科技有限公司

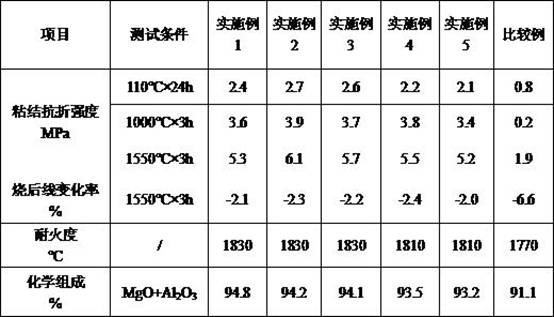

High-strength magnesium refractory mortar for refining steel ladle

ActiveCN114195529AHigh strengthReduce the amount of water addedMelt-holding vesselsProcess efficiency improvementCarboxymethyl celluloseBrick

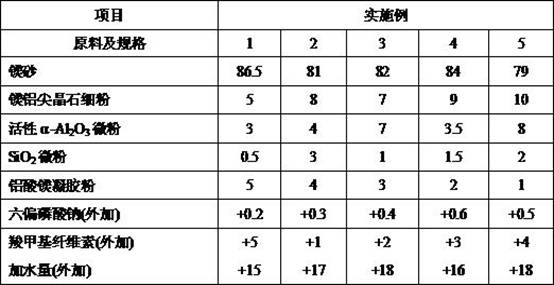

The invention relates to high-strength magnesium refractory mortar for refining a steel ladle. The refractory mortar is prepared from the following raw materials in percentage by weight: 79 to 87 percent of magnesia, 5 to 10 percent of aluminum-magnesium spinel fine powder, 3 to 8 percent of active alpha-Al2O3 micro powder, 0.5 to 3 percent of SiO2 micro powder and 1 to 5 percent of magnesium aluminate gel powder, and 0.2-0.6% of sodium hexametaphosphate and 1-5% of carboxymethyl cellulose are additionally added. The steel ladle bonding agent has good bonding strength, still has high strength, high temperature resistance and scouring resistance under the conditions of a steel ladle refining process and high temperature, and solves the problem that brick joints are most easily eroded in steel ladle application.

Owner:BAOSHAN IRON & STEEL CO LTD

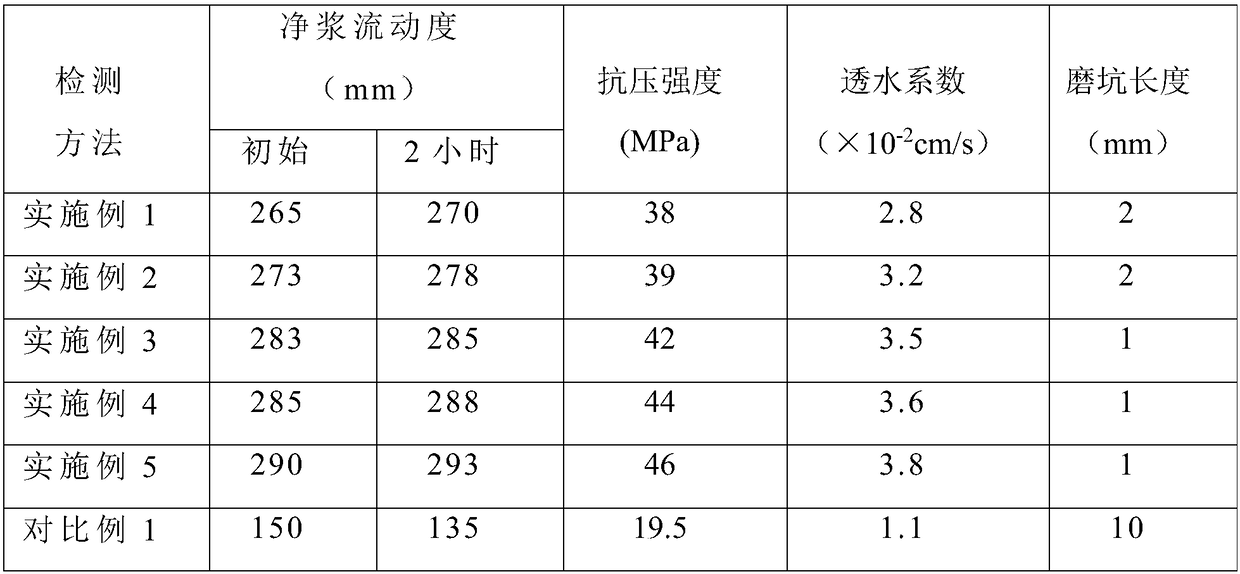

Environmental-friendly concrete additive and preparation method thereof

The invention discloses an environmental-friendly concrete additive. The additive is characterized in that the additive comprises, by weight, 12-15 parts of organic modified montmorillonoid, 1-4 partsof organic boron fiber, 1-3 parts of polyether phosphate amine salt and 1-4 parts of surface active agent. The invention further discloses a preparation method of the environmental-friendly concreteadditive. The method comprises the steps that components are uniformly mixed according to a proportion, dried, added into a ball grinding mill and milled for 15-25 minutes, and the environmental-friendly concrete additive is discharged. By means of the additive, the defects of higher cost, severe environmental pollution, single performance, limited improving capability of concrete performance andthe like of traditional concrete additives are overcome. Compared with concrete which is added with the traditional normal concrete additive, concrete which is added with the environmental-friendly concrete additive has lower price, slighter environmental pollution, greater performance improvement, and higher strength, fluidity, durability and water-tight performance.

Owner:黑龙江省龙建路桥第五工程有限公司

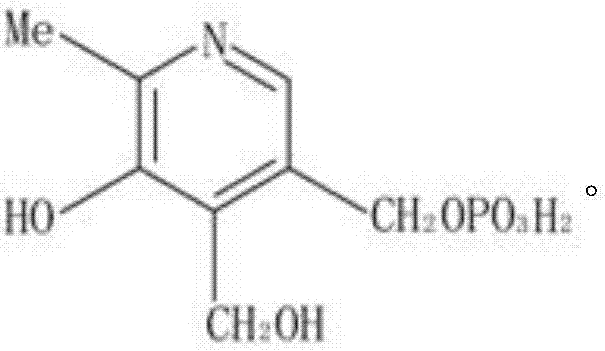

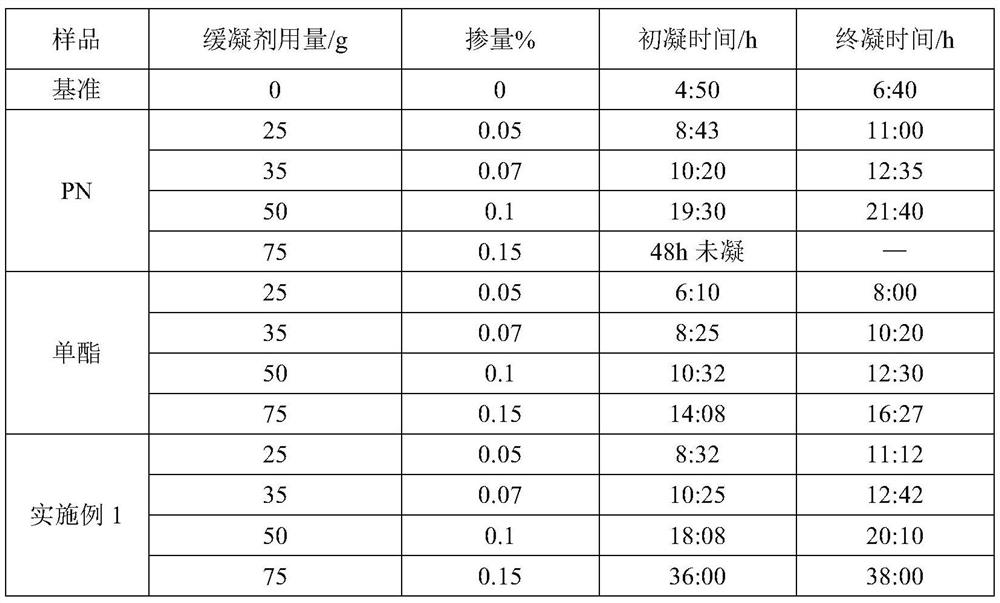

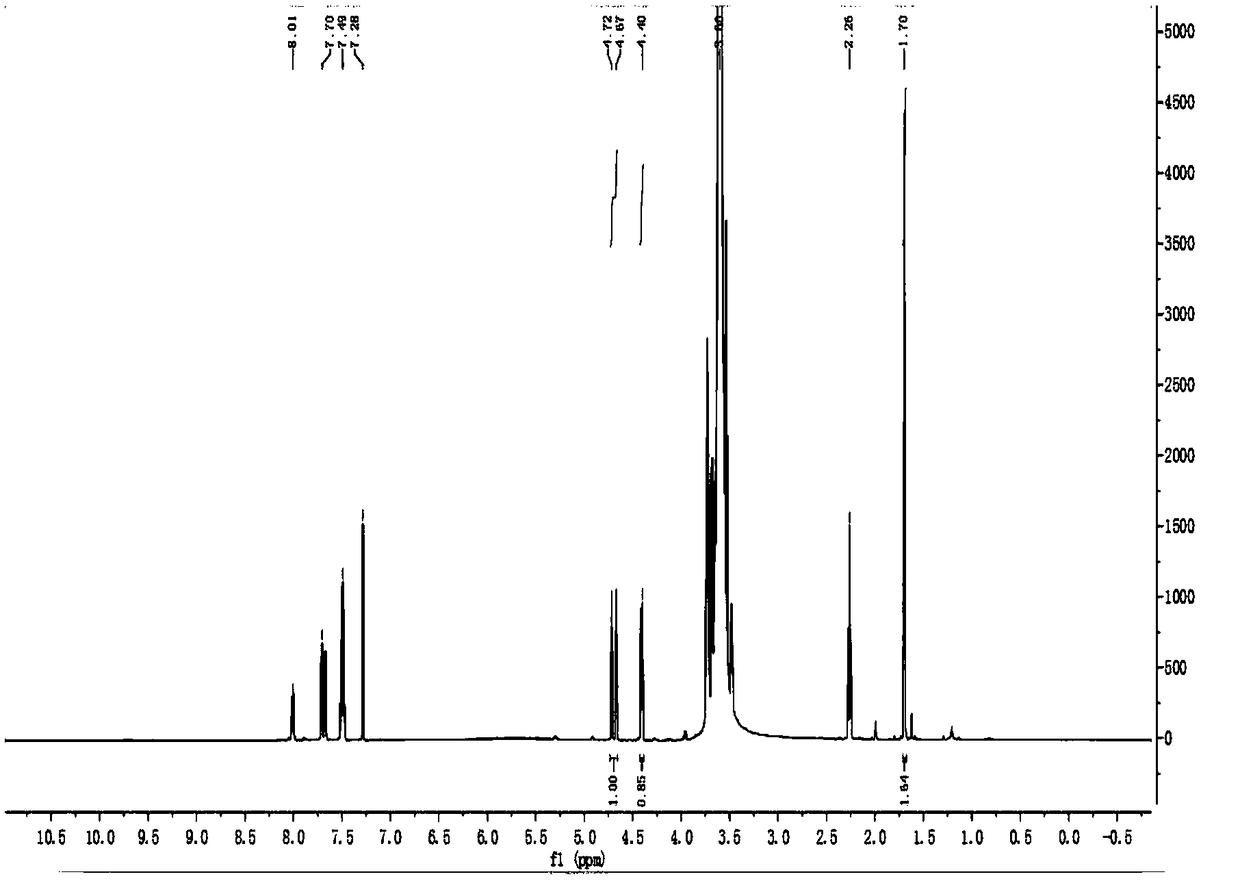

Modified malt syrup retarder as well as preparation method and application thereof

The invention discloses a modified maltose syrup retarder as well as a preparation method and application thereof. The modified maltose syrup retarder is prepared from maltose syrup, acrylic acid, an activating agent, unsaturated acid, esters, acrylamide, an initiator, deionized water and liquid caustic soda in a mass part ratio of (79-157):(10-40):(0.5-3.2):(40-80):(20-40):(20-40):(1-5):(500-750):(8-15). The preparation method comprises the following steps: putting malt syrup and acrylic acid into a No.1 reaction kettle according to the mass part ratio of (4-8):1, further adding an activating agent which is 0.5-2% of the total amount of the malt syrup, heating to 70-90 DEG C, stirring and reacting for 4 hours, and cooling to room temperature to obtain an intermediate product A; then adding the intermediate product A, unsaturated acid, esters, acrylamide, an initiator and deionized water in a mass ratio of (100-200):(40-80):(20-40):(20-40):(1-5):(500-750) into a No.2 reaction kettle, heating to 85-90 DEG C, stirring the mixture to react for 4 hours, cooling a reaction product to room temperature, and regulating the pH value to be about 7 by using liquid caustic soda to obtain the modified malt syrup retarder.

Owner:云南森博混凝土外加剂有限公司

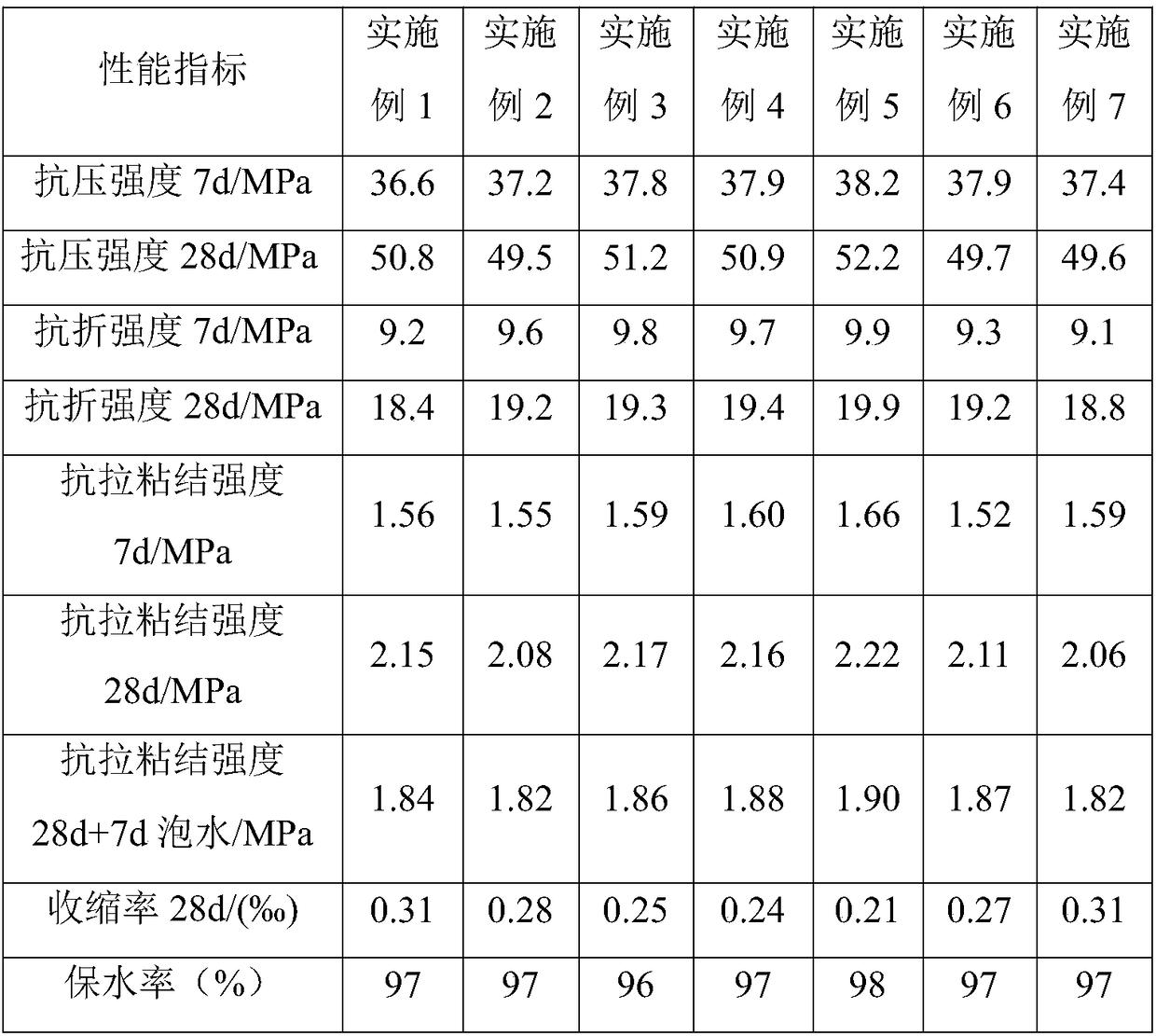

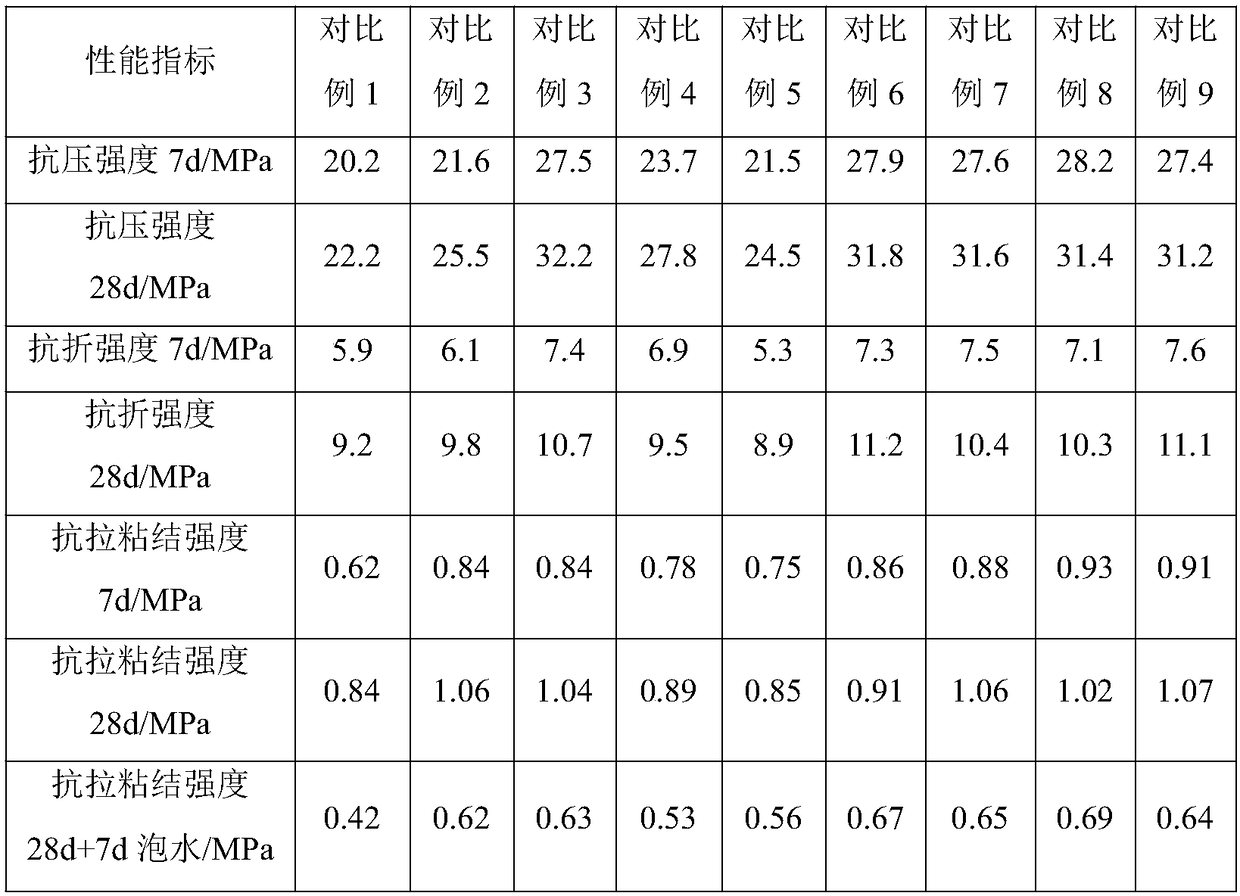

Special joint filling mortar for light partition wallboards

The invention discloses special joint filling mortar for light partition wallboards. The special joint filling mortar comprises, by weight, 300-400 parts of cement, 100-140 parts of fly ash, 400-450 parts of fine sand, 30-60 parts of calcined gypsum powder, 2-10 parts of macromolecule xanthan gum powder, 1-10 parts of redispersible latex powder, 1-3 parts of starch ether, 1-3 parts of cellulose ether, 1-3 parts of set retarders, 40-60 parts of expansive agents, 2-8 parts of graphene oxide modified carbon fibers and 1-5 parts of water repellents. A mass ratio of the macromolecule xanthan gum powder to the redispersible latex powder is 2-7:1; an expansion coefficient of the calcined gypsum powder is 120-130, and a mass ratio of graphene oxide to carbon fibers is 0.05-0.1:1. The special jointfilling mortar for the light partition wallboards has the advantages that various components of the special joint filling mortar are selected, the weights of the various components are matched with one another, respective excellent properties of the various components are comprehensively utilized, the strength of the components is drawn, and accordingly the special joint filling mortar is high inbonding strength, tensile and compressive property and water retention rate and low in shrinkage.

Owner:GUANGDONG FUTE NEW MATERIALS TECH CO LTD

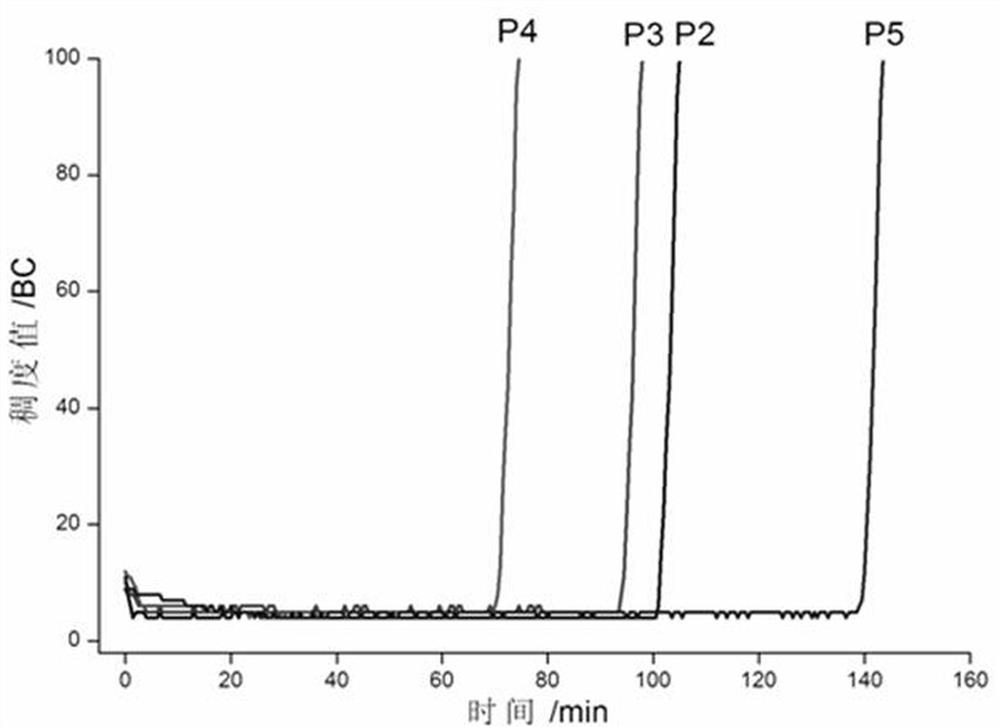

A modified aluminate cement retarder and its preparation method and application

ActiveCN108585583BImproved right-angle thickening propertiesPlay a role in stopping retardationAluminateHydration reaction

The invention discloses a modified aluminate cement retarder as well as a preparation method and application thereof and belongs to the technical field of cement retarding. The modified aluminate cement retarder comprises AMPS, unsaturated carboxylic acid, boric acid and glucose. The boric acid and the unsaturated carboxylic acid are combined and the boric acid forms a compact calcium borate covering layer by adsorbing calcium ions, so that the hydration reaction process of the cement is blocked and the early strength of cement stones is influenced. The structure of the calcium borate coveringlayer is damaged by doping a large amount of hydroxyl acid, so that cement particles can continuously perform hydration reaction under the damage of the covering layer after a period of time, and theeffect of stopping retarding is achieved. The content of the unsaturated carboxylic acid is high, and the carboxylic group in the retarder can achieve the retarding effect and also can improve the right angle thickening property of cement slurry.

Owner:JIAHUA SPECIAL CEMENT

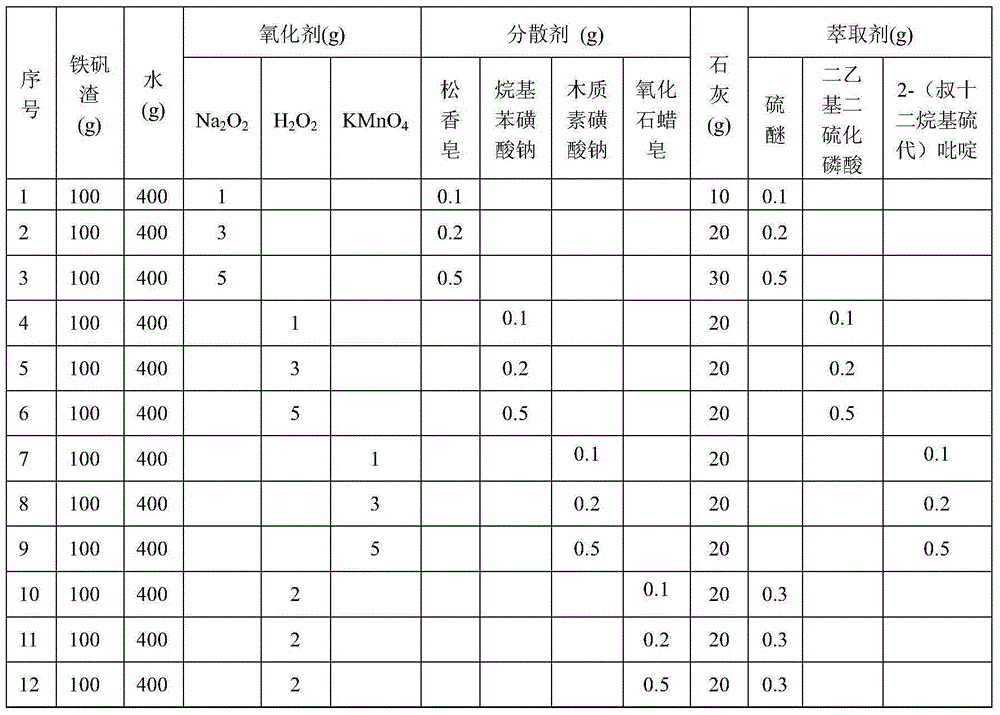

Method for preparing alkali-slag cement retarder through jarosite slag

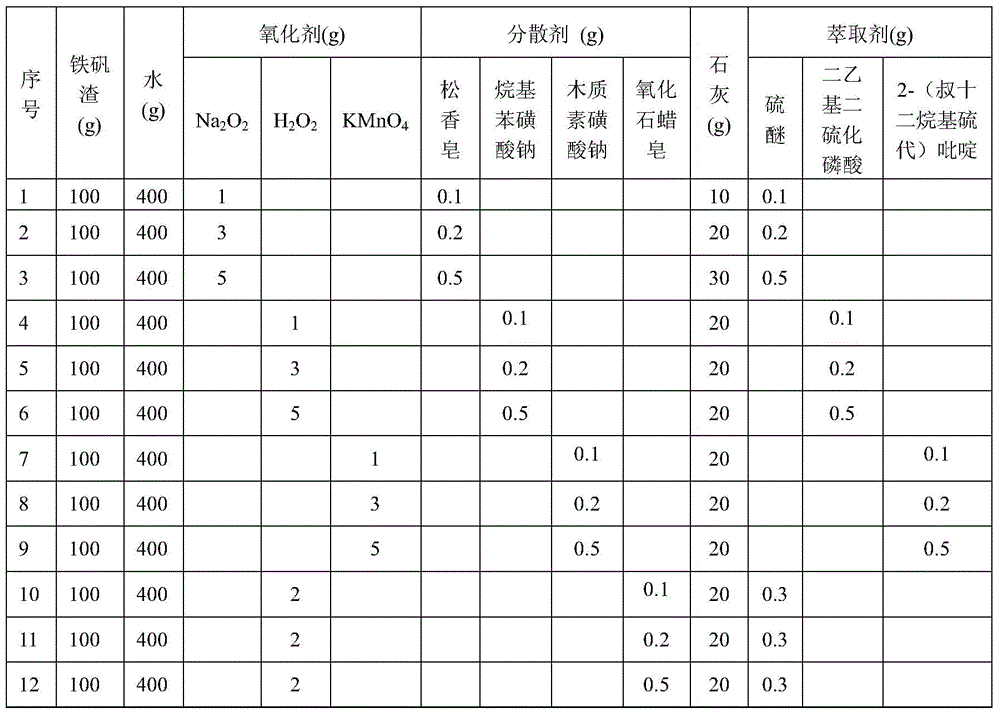

The invention discloses a method for preparing an alkali-slag cement retarder through jarosite slag. The method sequentially comprises the steps that a dispersing agent, the jarosite slag and an oxidizing agent are added into water and evenly stirred, lime is added, even stirring is carried out, and the mixture stands to achieve solid-liquid separation; solid phases obtained after solid-liquid separation are dried, and the alkali-slag cement retarder is obtained; an extraction agent is added into liquid phases obtained after solid-phase separation, valuable metal silver is recycled, and extraction liquid is recycled as water used in the first step. The method is simple and good in effect and has a significant benefit.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of high-temperature-resistant modified retarder

The invention relates to a preparation method of a high-temperature-resistant modified retarder, belonging to the technical field of sealing materials. According to the technical scheme, a silicon carbide whisker is utilized for modification, and a laminar matrix material is prepared through coating, so that on one hand, a polymer is endowed with the rigidity and thermal stability of an organic material, namely a laminar matrix substance, through the addition of the laminar matrix substance; on the other hand, the partial polymer is inserted among laminar inorganic material slice layers, the partial thermal decomposition effect is effectively shielded by the slice layer structures, and the micromolecule motion caused during the thermal decomposition is impeded, so that the polymer represents good heat stability. According to the retarder prepared by virtue of the scheme, polar groups are effectively released to the surface of cement particles to form an adsorption layer, and the adsorption layer is capable of preventing the contact between the cement and water so as to decrease the cement hydration speed and achieve a retarding effect, so that the heat stability of the material isimproved.

Owner:蒋留平

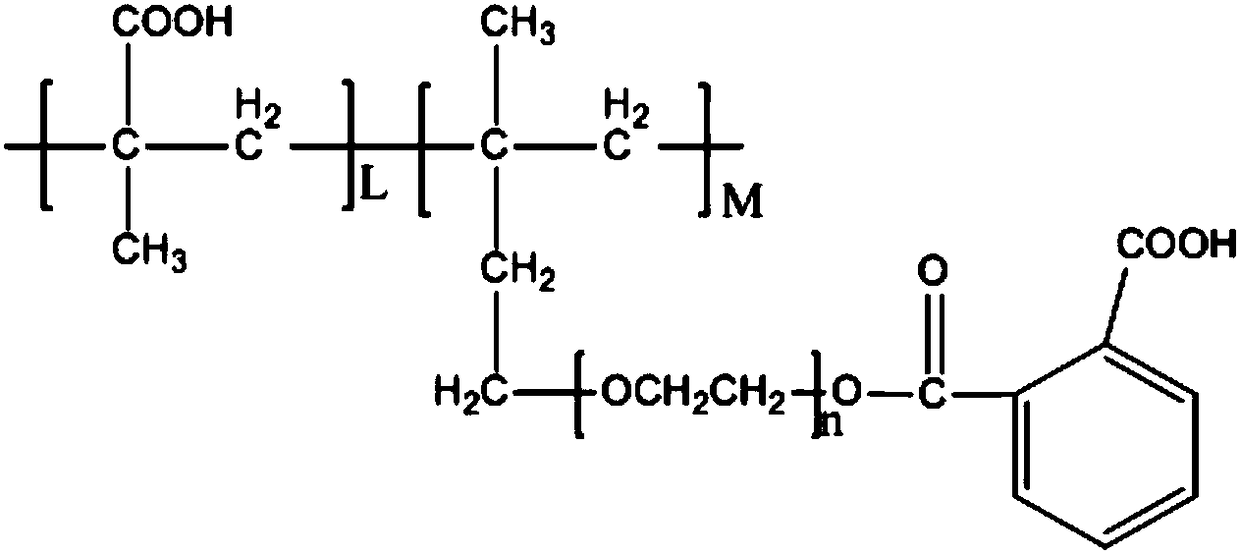

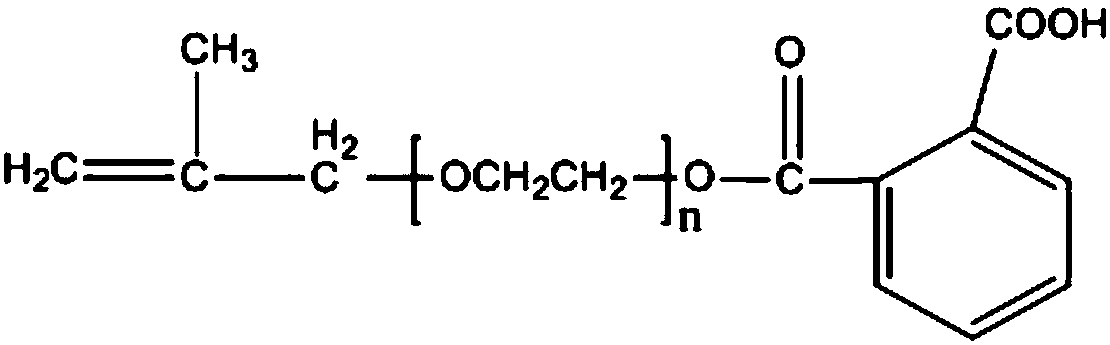

Phthalic anhydride-modified polycarboxylic acid water reducing agent and preparation method thereof

The invention belongs to the technical field of concrete admixtures and discloses a phthalic anhydride-modified polycarboxylic acid water reducing agent and a preparation method thereof. The method comprises: carrying out esterification on phthalic anhydride and methallyl polyoxyethylene ether at a temperature of 50 to 70 DEG C to obtain a phthalic anhydride-modified macromonomer, carrying out copolymerization on the phthalic anhydride-modified macromonomer and acrylic acid in a redox system at 30-60 DEG C, uniformly stirring the mixture, and adjusting product pH to 6-7 so that a polycarboxylic acid water reducing agent mother liquid containing a phthalic anhydride group is obtained. The preparation method is free of separation purification of the intermediate modified macromonomer and iseasy to operate, the reaction condition is easy to control, the impurities are not introduced, and the synthetic polycarboxylic acid water reducing agent has good dispersibility and good flow retention.

Owner:西安亿诺建材科技有限公司

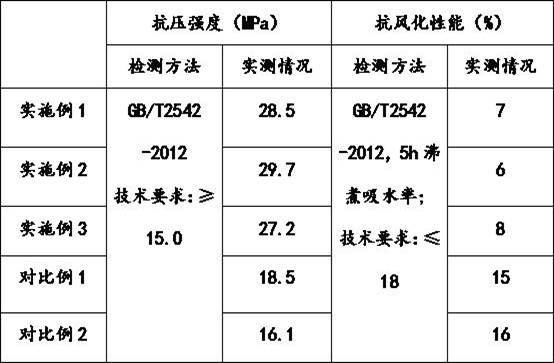

Baking-free brick and preparation method thereof

The invention provides a baking-free brick. The baking-free brick is prepared from the following raw materials in parts by weight: 800-1000 parts of building residue soil; 200-300 parts of rice fieldstraw; 80-120 parts of cement; 22-30 parts of slaked lime; 25-35 parts of gypsum; 8-12 parts of a curing agent; 3-5 parts of an active agent; 1-3 parts of a weather-resistant agent; 100-150 parts of water. Sodium lignosulfonate is a natural high-molecular polymer and an anionic surfactant, has very strong dispersing capacity, and is suitable for dispersing solids in an aqueous medium. The sodium lignosulfonate can be adsorbed on the surface of various solid particles and can be used for metal ion exchange. The sodium lignosulfonate is used as a dispersing agent and a wetting agent, and is mixed with a soil body to generate a series of physical and chemical reactions, and a thin layer of water film wrapping the surface of each fine particle is removed so that the engineering property of thesoil body is changed, and the strength and the water resistance of the baking-free brick are effectively improved.

Owner:苏珏

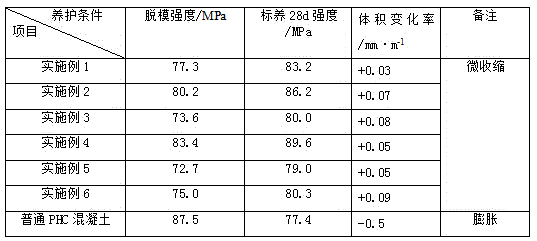

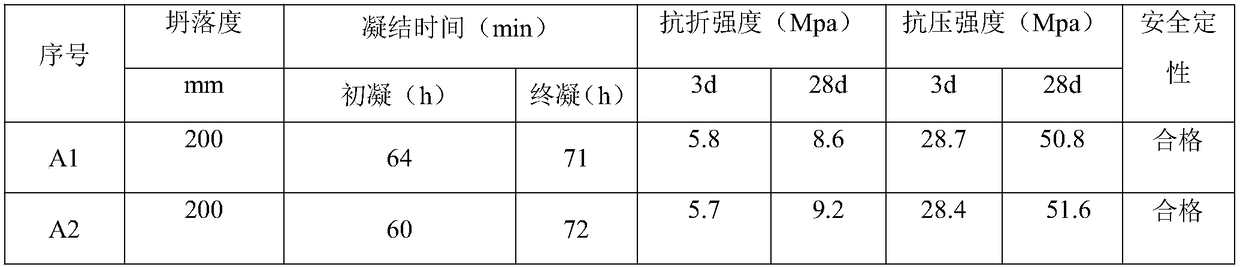

Gel material for autoclaving-free PHC tubular pile

ActiveCN105541215AInhibits hydration processRetarding effectSolid waste managementPhosphorPortland cement

The invention discloses a gel material for an autoclaving-free PHC tubular pile and belongs to the technical field of cement. The gel material comprises, by mass, 75-97% of portland cement clinker, 1-20% of phosphor slag, 2-5% of silica fume and 0-0.15% of sodium gluconate. The gel material has the advantages of good volume stability and high endurance and can be maintained at a temperature of 80-100 DEG C so that a construction period is shortened and an engineering cost is reduced.

Owner:JIAHUA SPECIAL CEMENT

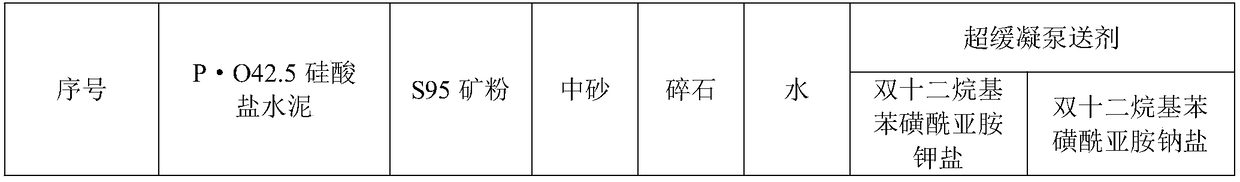

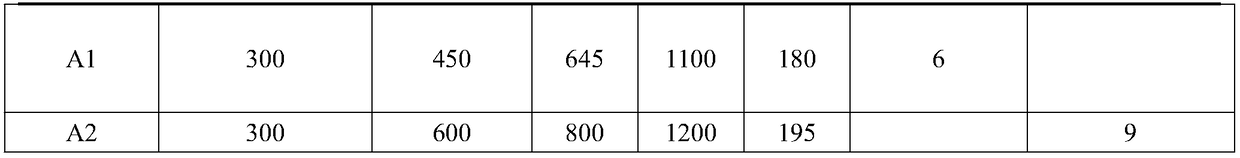

Pumping impervious super-set-retarding concrete and preparation method thereof

The invention discloses pumping impervious super-set-retarding concrete. The pumping impervious super-set-retarding concrete is prepared from, by weight, 1 part of cement, 1-2 parts of mineral powder,2-3 parts of medium sand, 3-4 parts of gravel, 0.6-0.7 part of water and 0.02-0.03 part of super-set-retarding pumping agent. A preparation method of the super-set-retarding pumping agent includes the steps that dodecylbenzene sulfonic acid and ammonia gas react in an organic solvent, after obtained reaction liquid of bis-dodecyl benzenesulfonimide is neutralized with alkaline matter, static layering is carried out, organic phases are removed, obtained water phases are concentrated and dried, and the pumping impervious super-set-retarding concrete is obtained. The alkaline matter is one of potassium hydroxide, sodium hydroxide, potassium carbonate and sodium carbonate. The newly-developed super-set-retarding concrete replaces an existing common set-retarding pumping agent, the set-retarding time initial set of the concrete is longer than 65 hours, the final set is shorter than 80 hours, later strength is achieved, and the strength of 28 d is qualified.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Production method of residual grout free pressure steam free C80 concrete pile

ActiveCN105384408AConsistent initial setting timeIssues Affecting DurabilitySuperplasticizerWater reducer

The invention discloses a production method of a residual grout free pressure steam free C80 concrete pile, and belongs to the technical field of concrete piles. The method comprises the following steps: (1) adding medium sand, stone, silicate cement clinker, mineral powder, silica fume, and sodium gluconate into a stirring machine, stirring the materials for 60 to 70 seconds, finally adding water and a naphthalene high efficient water reducer, and stirring for 90 to 120 seconds; (2) subjecting the concrete obtained in the step (1) to material distribution, mould assembly, and a stretch-draw treatment, and saving the piles for later use; (3) subjecting the piles obtained in the step (2) to centrifugation; (4) after centrifugation, maintaining the piles in a steam maintenance tank. Gypsum-free silicate cement is adopted and is compounded with mineral powder and silica fume to prepare a gel material, and the introduction of sulfate ions is avoided, so that the delayed ettringite reactions will not happen during the maintenance process of concrete at a temperature of 80 to 100 DEG C, and the endurance of piles is enhanced.

Owner:EMEISHAN QIANGHUA SPECIAL CEMENT

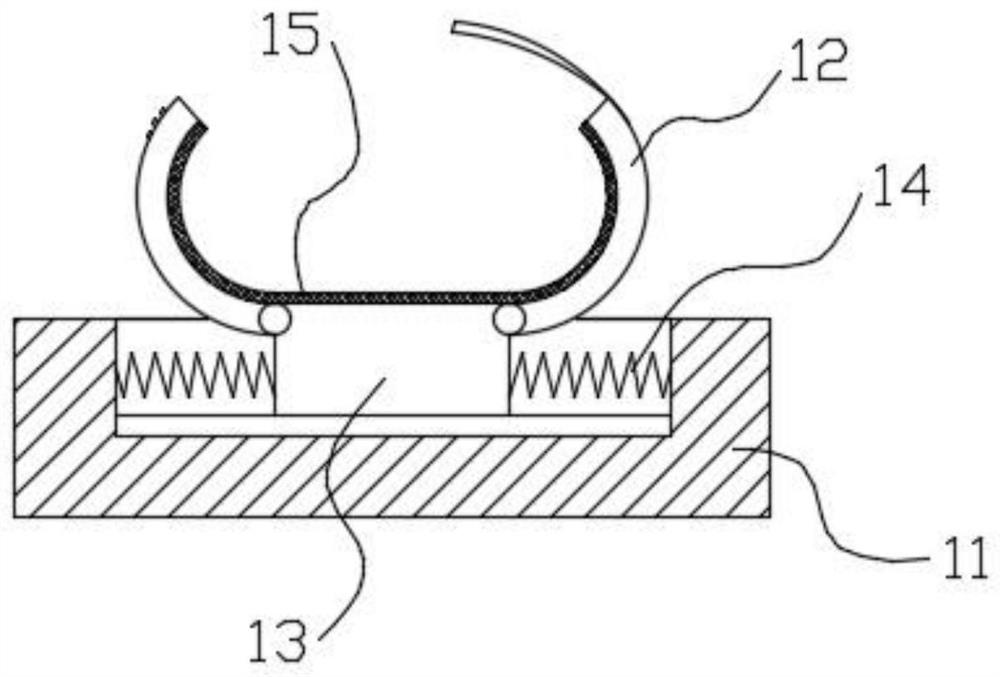

Adjustable head and neck body position fixator

The invention discloses an adjustable head and neck body position fixator. The fixator comprises a head fixing mechanism, a neck fixing mechanism and a chest fixing mechanism, the neck fixing mechanism comprises an open-ring-shaped neck sleeve and an arc-shaped pillow connected to the neck sleeve, the neck sleeve is made of a flexible material, and the pillow is detachably connected with the frontchest side of the chest fixing mechanism through a first connecting belt. The defects that a patient feels uncomfortable and cannot insist for a long time due to traditional neck anteflexion are overcome, the neck anteflexion position of the patient can be kept in a comfortable state, and rehabilitation of the patient is promoted.

Owner:SICHUAN CANCER HOSPITAL

The method for preparing alkali-slag cement retarder with alum slag

The invention discloses a method for preparing an alkali-slag cement retarder through jarosite slag. The method sequentially comprises the steps that a dispersing agent, the jarosite slag and an oxidizing agent are added into water and evenly stirred, lime is added, even stirring is carried out, and the mixture stands to achieve solid-liquid separation; solid phases obtained after solid-liquid separation are dried, and the alkali-slag cement retarder is obtained; an extraction agent is added into liquid phases obtained after solid-phase separation, valuable metal silver is recycled, and extraction liquid is recycled as water used in the first step. The method is simple and good in effect and has a significant benefit.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com