Pumping impervious super-set-retarding concrete and preparation method thereof

An ultra-retarding and concrete technology, applied in the field of building materials, can solve problems such as prolonging, not affecting the later strength of concrete, retarding admixtures not meeting the requirements, etc., and achieving the effect of qualified strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The preparation of embodiment 1 ultra-retarded pumping agent

[0014] 1) Under nitrogen protection conditions, 400g ethyl acetate is added in the reactor of 1L, then reactor is cooled to 5 ℃, then adds dodecylbenzenesulfonic acid 326g (1.0mol) in reactor, then in Under the control of the flowmeter, slowly introduce 8.5g (0.5mol) of anhydrous ammonia gas into the reaction kettle within 1h. After the ammonia gas is introduced, continue the reaction at 5°C for 1-2h, then stop cooling, and the reaction solution will naturally warm up to room temperature. The reaction was continued for 48 hours. After the reaction was completed, an ethyl acetate solution of didodecylbenzenesulfonimide was obtained.

[0015] 2) Place the ethyl acetate solution of didodecylbenzenesulfonimide obtained in the previous step in a 1L reaction flask, cool it to 0-5°C with an ice-water bath, and slowly add 0.3mol of it dropwise while stirring / L of potassium hydroxide solution, the pH value of the s...

Embodiment 2

[0017] 1) Under nitrogen protection conditions, 400g ethyl acetate is added in the reactor of 1L, then reactor is cooled to 5 ℃, then adds dodecylbenzenesulfonic acid 326g (1.0mol) in reactor, then in Under the control of the flow meter, slowly introduce 8.5g (0.5mol) of anhydrous ammonia gas into the reaction kettle within 1h. After the ammonia gas is introduced, continue the reaction at 5°C for 1-2h, then stop cooling, and let the reaction solution warm up to room temperature naturally. , Continue to react for 48h, after the reaction is finished, the ethyl acetate solution of didodecylbenzenesulfonimide is obtained.

[0018] 2) Put the ethyl acetate solution of didodecylbenzenesulfonimide obtained in the previous step into a 1L reaction flask, cool it to 0-5°C with an ice-water bath, and slowly add 0.3mol of it dropwise while stirring / L of sodium hydroxide solution, the pH value of the solution is adjusted to 7, then the solution is placed in a separatory funnel for phase s...

Embodiment 3

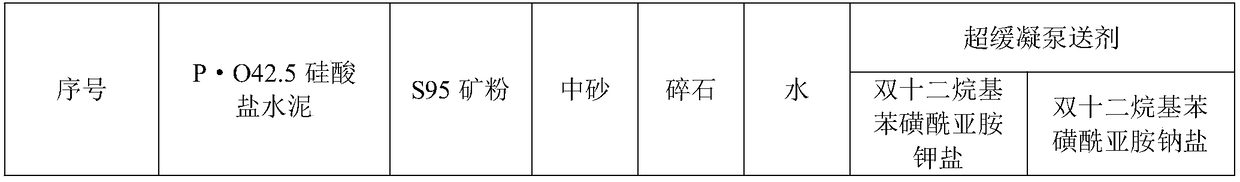

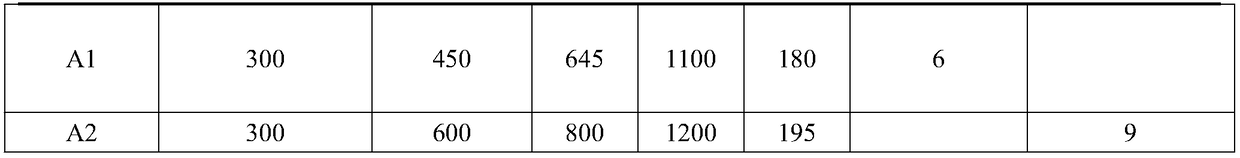

[0020] A pumping anti-seepage super retarded concrete, its batching is shown in Table 1;

[0021] Table 1 Pumping anti-seepage super retarded concrete mix ratio (kg / m3)

[0022]

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com