Concrete early-strength agent and preparation method thereof

An early-strength agent and concrete technology, applied in the field of concrete early-strength agent and its preparation, can solve the problems that the early strength of concrete cannot reach the expected value, the effect of the early-strength agent is not obvious, and the cement hydration time is long, etc. Increased strength, reduced impact, reduced corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

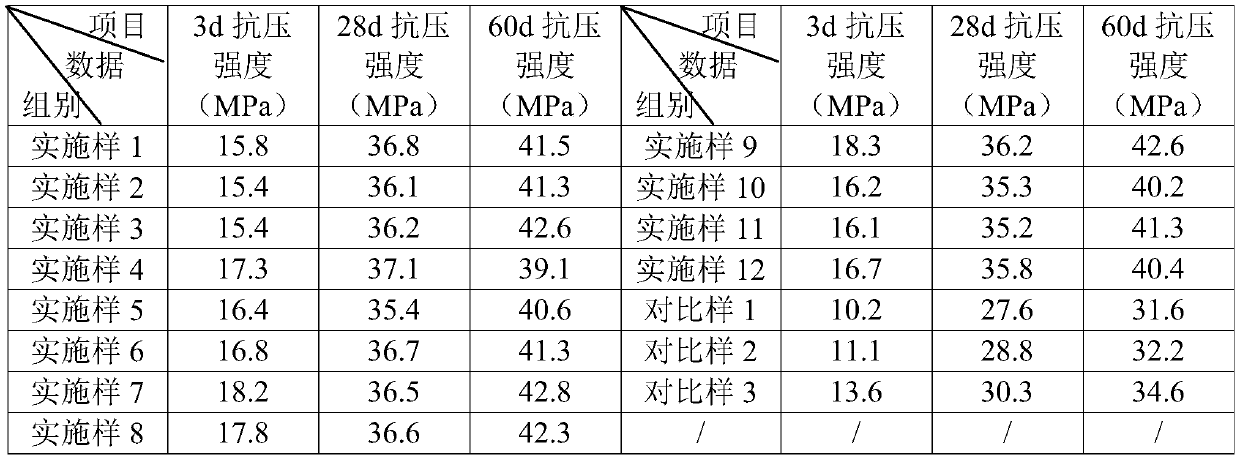

Examples

Embodiment 1-12

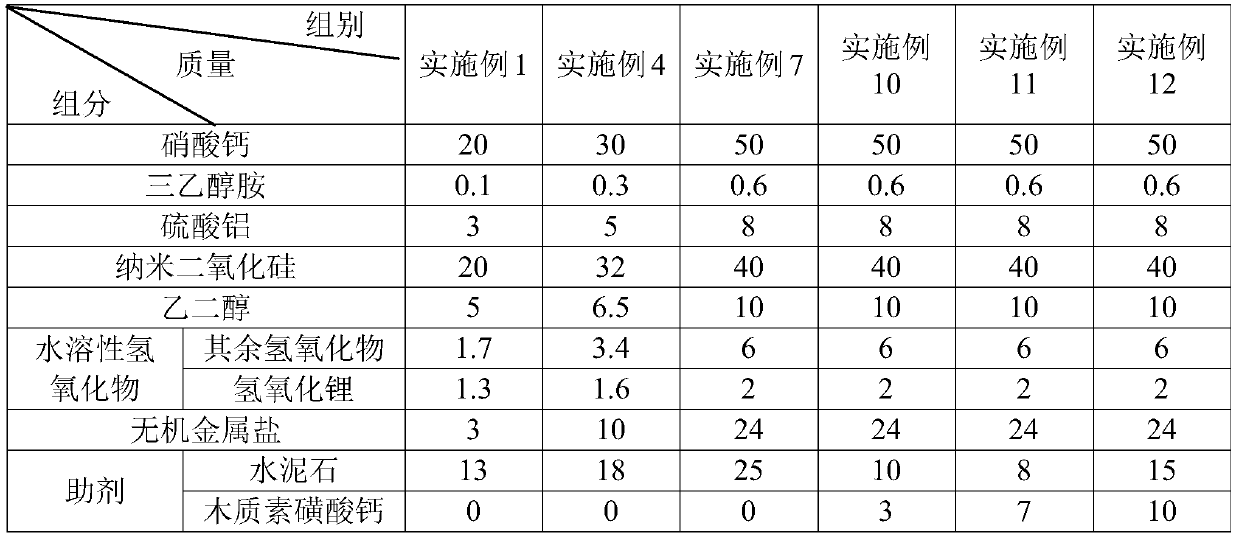

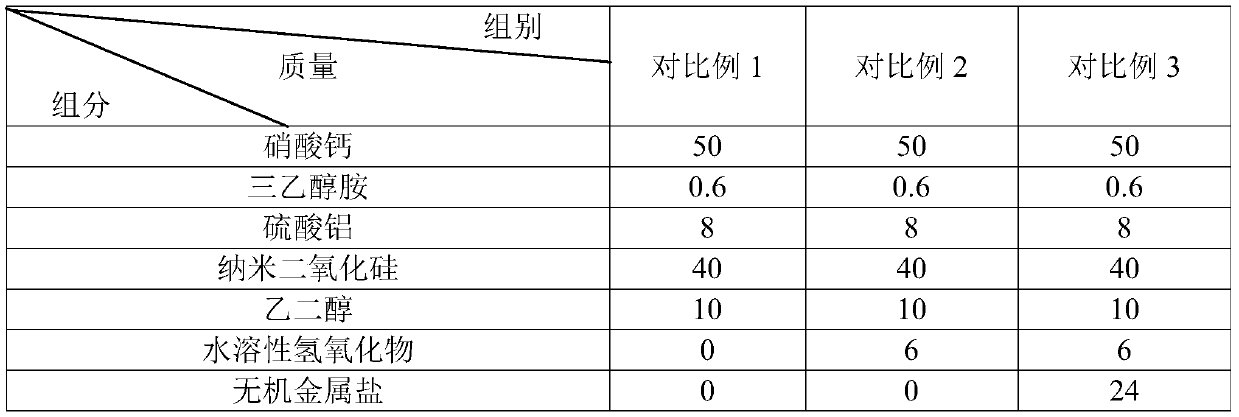

[0050] Embodiment 1-12: a kind of concrete early strength agent, the component that embodiment 1, 4, 7, 10-12 comprises and corresponding quality are as shown in table 1, and are prepared by the following steps:

[0051] S1: Mix calcium nitrate, triethanolamine, aluminum sulfate, nano-silica, ethylene glycol, and additives, keep warm at 35°C, and stir at a stirring speed of 30r / min for 25min to form mixture A;

[0052] S2: Cool the mixture A to 15°C, then put the water-soluble hydroxide and inorganic metal salt into the mixture A, stir at 15°C at a stirring speed of 30r / min for 25min, and obtain the early strengthening agent.

Embodiment 1

[0055] In embodiment 1, all the other hydroxides are sodium hydroxide, and the inorganic metal salt is magnesium carbonate.

Embodiment 2

[0056] Embodiment 2: a kind of concrete early strength agent, the difference with embodiment 1 is that all the other hydroxides in embodiment 2 adopt potassium hydroxide, and inorganic metal salt is the ferric chloride of 1kg and the magnesium sulfate of 2kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com