Retarded cement grinding aid and preparation method thereof

A cement grinding aid and retarding technology, which is applied in the field of cement grinding aids, can solve the problems of poor effect and high cost, and achieve the effects of saving cement consumption, small slump loss, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1: a kind of retarded cement grinding aid, composition is as follows:

[0013] Sodium carboxymethyl cellulose 0.01-0.02%,

[0015] Citric acid 5-10%,

[0016] The balance is water, and the total amount is 100%.

[0017] The preparation method of described retarded cement grinding aid, comprises the following steps,

[0018] Step (1): Inject water into the first reaction kettle, add sodium carboxymethyl cellulose while stirring, stir for 15 minutes, and prepare a sodium carboxymethyl cellulose solution with a weight percentage of 1%;

[0019] Step (2): Add citric acid to the remaining water while stirring in the second reaction kettle according to the formula ratio, then add calcium sugar and stir for 10 minutes, and then add the weight percentage prepared in step (1) to the second reaction kettle It is 1% sodium carboxymethyl cellulose solution, stirred for 10 minutes, and then filtered through 150 mesh stainless steel to ob...

Embodiment 2 to Embodiment 4

[0021] Repeat the method of Experimental Example 1 by each component content specified in the following table 1, obtain the retarded cement grinding aid product of different component content respectively,:

[0022] Table 1

[0023] components

Example 1

Example 2

Example 3

Example 4

[0024] Sodium carboxymethyl cellulose(%)

0.01

0.02

0.02

0.01

Calcium sugar (%)

25

27

29

30

Citric acid (%)

10

7

9

5

water(%)

64.99

65.98

61.98

64.99

get

Product 1

Product 2

Product 3

Product 4

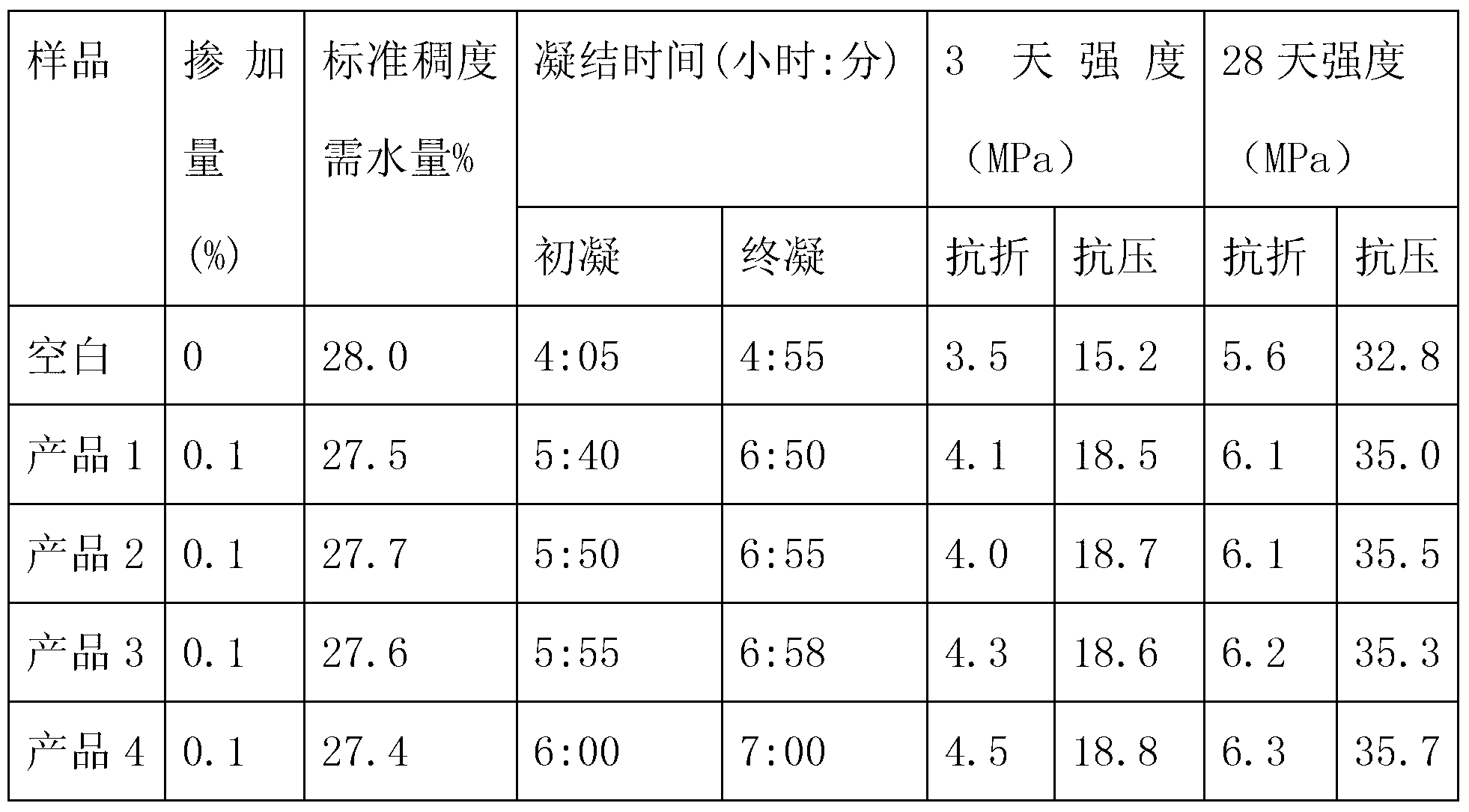

[0025] The retarded cement grinding aid products 1 to 4 prepared in Example 1 to Example 4 were used in the mixed material to carry out comparative experiments, wherein the proportion of the mixed material was: clinker 58%, desulfurized gypsum 5% , limestone 8%, fly ash 20%, slag 9%. The experimental results are shown in Table 2:

[0026] Table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com