High-performance compound polycarboxylate superplasticizer

A technology of polycarboxylate and water reducer, which is applied in the field of compound water reducer and high performance compound polycarboxylate water reducer, which can solve the problem of poor cement adaptability, insufficient slump retention performance, and easy bleeding and other problems, to achieve the effect of improving the retention effect, good plastic retention effect, and improving the quality of construction projects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

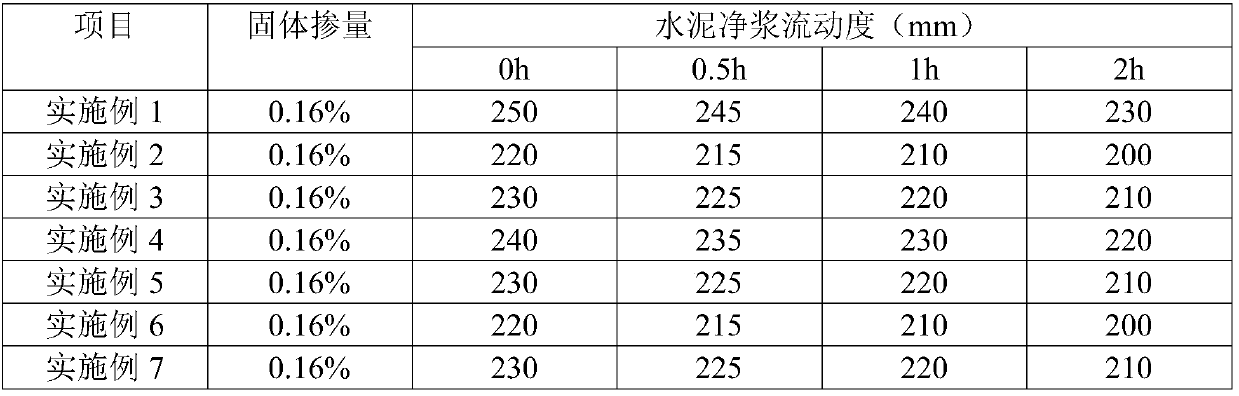

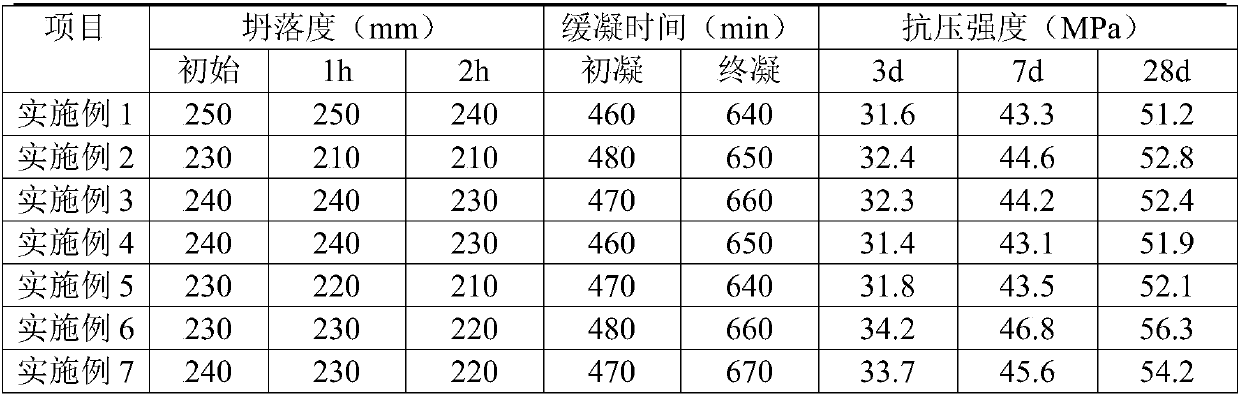

Examples

Embodiment 1

[0029] A high-performance composite polycarboxylate water-reducer, comprising, in parts by weight, 10 parts of polycarboxylate water-reducer, 1 part of methacrylate, 2 parts of tertiary carbonate, and 0.2 parts of N-acyl sarcosine , 2 parts of hydroxypropyl starch ether, 1 part of glycerin, 1 part of sodium dodecylbenzenesulfonate, and 15 parts of water.

[0030] The polycarboxylate water-reducer uses 2-methallyl polyoxyethylene ether, hydroxyethyl acrylate and sodium acrylate sulfonate in a molar ratio of 1:2.5:0.5 as monomers, and uses hydrogen peroxide, sodium persulfate, glucose Initiated by compounding with sodium thiosulfate, under the condition of 30-40 ℃, the polycarboxylate water reducer is synthesized by the free radical polymerization method in aqueous solution. The polycarboxylate water reducer is synthesized at low temperature, and the energy consumption is reduced and the production cost is saved through the compounding of monomers and compounding initiators. Th...

Embodiment 2

[0033] A high-performance composite polycarboxylate water reducer, including, by weight, 20 parts of polycarboxylate water reducer, 4 parts of methacrylate, 3 parts of tertiary carbonate, and 0.3 parts of N-acyl sarcosine , 4 parts of hydroxypropyl starch ether, 3 parts of glycerin, 3 parts of sodium dodecylbenzenesulfonate, 25 parts of water, and 1 part of treated animal hair.

[0034] The polycarboxylate water-reducer takes 2-methallyl polyoxyethylene ether, hydroxyethyl acrylate and sodium acrylate sulfonate as monomers in a molar ratio of 1:3.5:0.6, and uses hydrogen peroxide, sodium persulfate, glucose Initiated by compounding with sodium thiosulfate, polycarboxylate superplasticizer was synthesized by aqueous radical polymerization at 35°C.

[0035] The consumption of hydrogen peroxide is 1.4% of the quality of 2-methallyl polyoxyethylene ether, the consumption of sodium persulfate is 0.8% of the quality of 2-methallyl polyoxyethylene ether, and the glucose is 2-methally...

Embodiment 3

[0037] A high-performance composite polycarboxylate water-reducer, comprising, in parts by weight, 15 parts of polycarboxylate water-reducer, 2 parts of methacrylate, 2.5 parts of tertiary carbonate, and 0.2 part of N-acyl sarcosine , 3 parts of hydroxypropyl starch ether, 2 parts of glycerin, 2 parts of sodium dodecylbenzenesulfonate, 20 parts of water, 2 parts of treated animal hair.

[0038]The polycarboxylate water-reducer takes 2-methallyl polyoxyethylene ether, hydroxyethyl acrylate and sodium acrylate sulfonate as monomers with a molar ratio of 1:2.5:0.4, and uses hydrogen peroxide, sodium persulfate, glucose Initiated by compounding with sodium thiosulfate, polycarboxylate superplasticizer was synthesized by aqueous radical polymerization at 36°C.

[0039] The consumption of hydrogen peroxide is 1.6% of the quality of 2-methallyl polyoxyethylene ether, the consumption of sodium persulfate is 0.8% of the quality of 2-methallyl polyoxyethylene ether, and the glucose is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com