Cement paste system for long-cementing-section large-temperature-difference cementing

A large temperature difference, cement slurry technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of inability to condense, inability to eliminate the influence of temperature difference effect on cement stone strength, slow compressive strength in low temperature area, etc. The effect of reducing dosage, low cost and reducing the ratio of calcium to silicon in cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

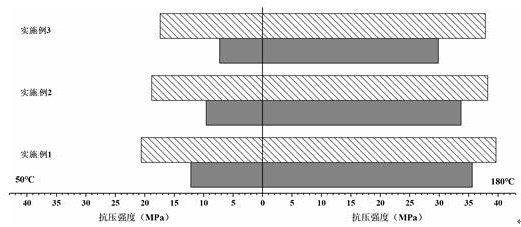

Embodiment 1

[0046] Grade G cement 88% + waste silica brick powder 10% + suspension stabilizer 1% + fluid loss reducer 4% + retarder 1%, water cement ratio 0.44.

Embodiment 2

[0048] Grade G cement 81% + waste silica brick powder 15% + suspension stabilizer 2% + fluid loss reducer 6% + retarder 2%, water cement ratio 0.44.

Embodiment 3

[0050]Grade G cement 74% + waste silica brick powder 20% + suspension stabilizer 3% + fluid loss reducer 8% + retarder 3%, water-cement ratio 0.44.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com