A cement slurry system for long sealing section and large temperature difference cementing

A large temperature difference, cement slurry technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of slow compressive strength in low temperature area, unable to eliminate the influence of temperature difference effect on cement stone strength, and unable to set, etc. The effect of reducing the calcium-silicon ratio of cement, low cost and reducing dosage

Active Publication Date: 2022-08-05

JIAHUA SPECIAL CEMENT

View PDF21 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the defects and deficiencies in the above-mentioned prior art, the present invention provides a cement slurry system for well cementing with a large temperature difference in the long sealing section. Influenced by the strength of the cement stone formed by it, the compressive strength develops slowly in the low temperature area at the top of the well section, and even cannot be condensed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

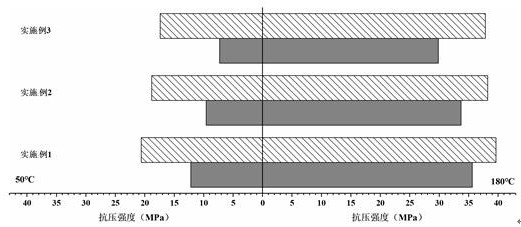

Embodiment 1

[0046] G -class cement 88%+waste silicon brick powder 10%+suspended stabilizer 1%+1%of water loss agent 4%+slowing agent 1%, water and ash ratio 0.44.

Embodiment 2

[0048] G -class cement 81%+waste silicon brick powder 15%+suspended stabilizer 2%+low water loss agent 6%+slow coagulant 2%, water and ash ratio 0.44.

Embodiment 3

[0050]G -class cement 74%+waste silicon brick powder 20%+suspended stabilizer 3%+3%of the water loss agent 3%, water and ash ratio 0.44.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Login to View More

Abstract

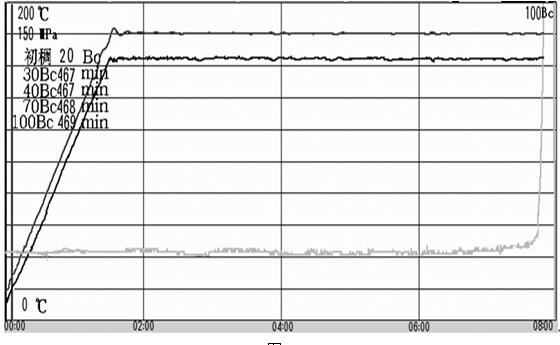

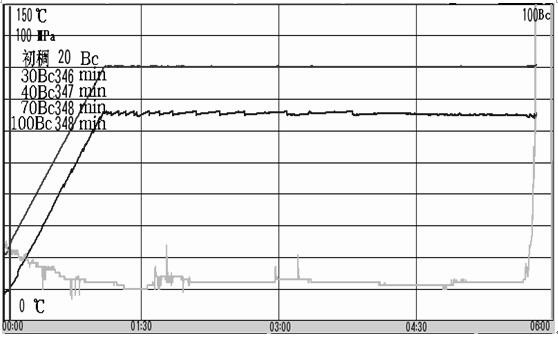

The invention discloses a cement slurry system for cementing with a long sealing section and a large temperature difference, and relates to the technical field of cementing materials in oil and gas fields. The cement slurry of the present invention is composed of 74-88 wt% oil well cement, 4-8 wt% fluid loss agent, 1-3 wt% suspension stabilizer, 10-20 wt% high temperature strength stabilizer, 1-3 wt% % retarder; retarder is made up of ethylenediaminetetramethylenephosphonate sodium, borax and terpolymer; terpolymer is sodium methacrylate sulfonate, isopentene Alcohol polyvinyl ether and maleic anhydride are used as monomers and are prepared by free radical solution copolymerization. The cement slurry of the invention has a wide service temperature range, which can meet the setting retardation effect of the cement slurry in the entire temperature range of the upper and lower ends of the cement slurry well section in the cementing construction, which are respectively 50° C. and 180° C. Under the environment of high temperature and large temperature difference of 50 °C, it can have a certain strength and avoid the "super-retardation phenomenon" of the top cement.

Description

Technical field [0001] The present invention involves the field of oil and gas field solid well materials technology. It is more specifically involved in a long -sealing solid section large temperature difference. The cement slurry system is involved. Background technique [0002] With the continuous deepening of oil and gas exploration and development, the targets of exploration and development are becoming increasingly complicated. More than 40% of the remaining oil and gas resources in China are distributed in deep, and deep oil and gas resources must be used in oil and gas production. The number of deep well -deep well drilling is increasing. It brought severe challenges to Gujing's work. The complex stratum long section large temperature difference and solid well technology has become one of the bottleneck technology issues restricting exploration and development. [0003] High temperature and large temperature difference solid well requires cement slurry to ensure both safe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/467C08F283/06C08F228/02C08F222/06

CPCC09K8/467C08F283/065C08F228/02C08F222/06

Inventor 赵峰古安林曾雪玲龙丹

Owner JIAHUA SPECIAL CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com