A kind of retarder suitable for cementing with large temperature difference and preparation method thereof

A technology of retarder and large temperature difference, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of inability to eliminate the influence of cement stone strength, inability to set, slow development of compressive strength of cement slurry, etc. Wide use temperature range, increase slurry consistency, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

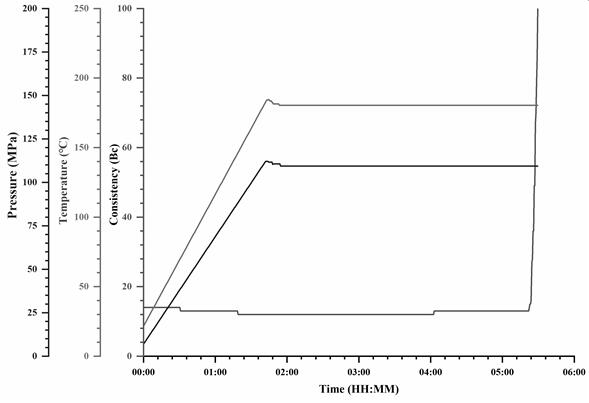

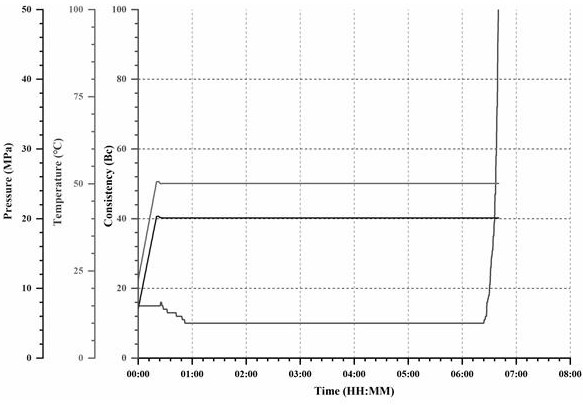

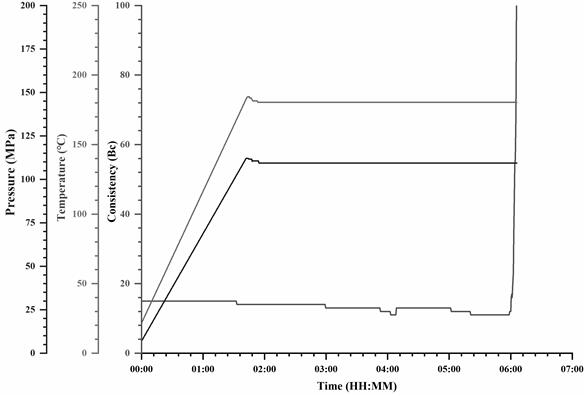

Image

Examples

Embodiment 1

[0039] As a preferred embodiment of the present invention, this embodiment discloses:

[0040] Preparation of terpolymers:

[0041] A1. Accurately weigh sodium methacrylate sulfonate, prenyl polyvinyl ether and maleic anhydride in turn according to the design ratio of each monomer; dissolve the weighed three monomers with pure water to obtain a three-monomer mixed solution ;

[0042] A2, using the aqueous solution of NaOH to adjust the pH value of the three-monomer mixed solution obtained in step A1 to 5, after fully mixing, transfer the three-monomer mixed solution after adjusting the pH value to a three-necked flask;

[0043] A3, feed nitrogen into the three-necked flask in step A2, and exclude oxygen;

[0044] A4. The ammonium persulfate aqueous solution was added dropwise to the three-necked flask using a constant pressure funnel device for reaction, the reaction temperature was 70°C, and the reaction time was 6h;

[0045]A5. After the reaction in step A4 is completed, ...

Embodiment 2

[0049] As another preferred embodiment of the present invention, this embodiment discloses:

[0050] Preparation of terpolymers:

[0051] A1. Accurately weigh sodium methacrylate sulfonate, prenyl polyvinyl ether and maleic anhydride in turn according to the design ratio of each monomer; dissolve the weighed three monomers with pure water to obtain a three-monomer mixed solution ;

[0052] A2, using the aqueous solution of NaOH to adjust the pH value of the three-monomer mixed solution obtained in step A1 to 5, after fully mixing, transfer the three-monomer mixed solution after adjusting the pH value to a three-necked flask;

[0053] A3, feed nitrogen into the three-necked flask in step A2, and exclude oxygen;

[0054] A4. The ammonium persulfate aqueous solution was added dropwise to the three-necked flask using a constant pressure funnel device for the reaction, the reaction temperature was 75°C, and the reaction time was 6h;

[0055] A5. After the reaction in step A4 is ...

Embodiment 3

[0059] This embodiment discloses a conventional cement slurry formula: G-grade cement 76.5% + silica sand 20% + suspension stabilizer 2% + fluid loss agent 6% + citric acid 1.5%, water-cement ratio 0.44.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com