Modified malt syrup retarder as well as preparation method and application thereof

The technology of maltose syrup and retarder is applied in the field of modified maltose syrup retarder and its preparation. The effect of improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 400kg of maltose syrup and 100kg of acrylic acid into the No. 1 reactor, then add 4kg of sodium bicarbonate into the No. 1 reactor, turn on the agitator, raise the temperature to 70-90°C for 4 hours, and cool down to room temperature to obtain the monoester. Then 100kg of monoester, 20kg of methacrylic acid, 20kg of maleic acid, 5kg of hydroxyethyl acrylate, 15kg of diethyl dithiophosphate, 20kg of acrylamide, 1kg of potassium persulfate and 500kg of Put the ionized water into the No. 2 reaction kettle, turn on the agitator, raise the temperature to 85-90°C and stir for 4 hours, cool down to room temperature, then add 8kg of sodium hydroxide solution to adjust the pH to about 7 to obtain the modified maltose syrup retarder.

Embodiment 2

[0038] Put 800kg of maltose syrup and 100kg of acrylic acid into the reactor, then add 4.8kg of concentrated sulfuric acid into the No. 1 reactor, turn on the agitator, raise the temperature to 70-90°C for 4 hours, and cool down to room temperature to obtain the monoester. Then 100kg of monoester, 20kg of acrylic acid, 20kg of maleic acid, 5kg of ethylene glycol dimethacrylate, 15kg of blocked amide phosphate, 20kg of acrylamide, 1kg of ammonium persulfate and 500kg of deionized Put water into No. 2 reactor, turn on the agitator, raise the temperature to 85-90°C and stir for 4 hours, cool down to room temperature, then add 8kg of sodium hydroxide solution to adjust the pH to about 7 to obtain the modified maltose syrup retarder.

Embodiment 3

[0040]Put 800kg of maltose syrup and 100kg of maleic anhydride into No. 1 reactor, then add 9.6kg of caustic soda into No. 1 reactor, start the stirrer, raise the temperature to 70-90°C for 4 hours, cool down to room temperature to obtain single ester. Then the monoester of 200kg, the methacrylic acid of 50kg, the fumaric acid of 30kg, the diethyl dithiophosphate of 10kg, the polyethylene glycol diacrylate of 30kg, the acrylamide of 40kg, the ammonium persulfate of 5kg and Put 750kg of deionized water into the No. 2 reaction kettle, turn on the agitator, raise the temperature to 85-90°C and stir for 4 hours, cool down to room temperature, and then add 15kg of sodium hydroxide solution to adjust the pH to about 7 to obtain the modified maltose syrup. coagulant.

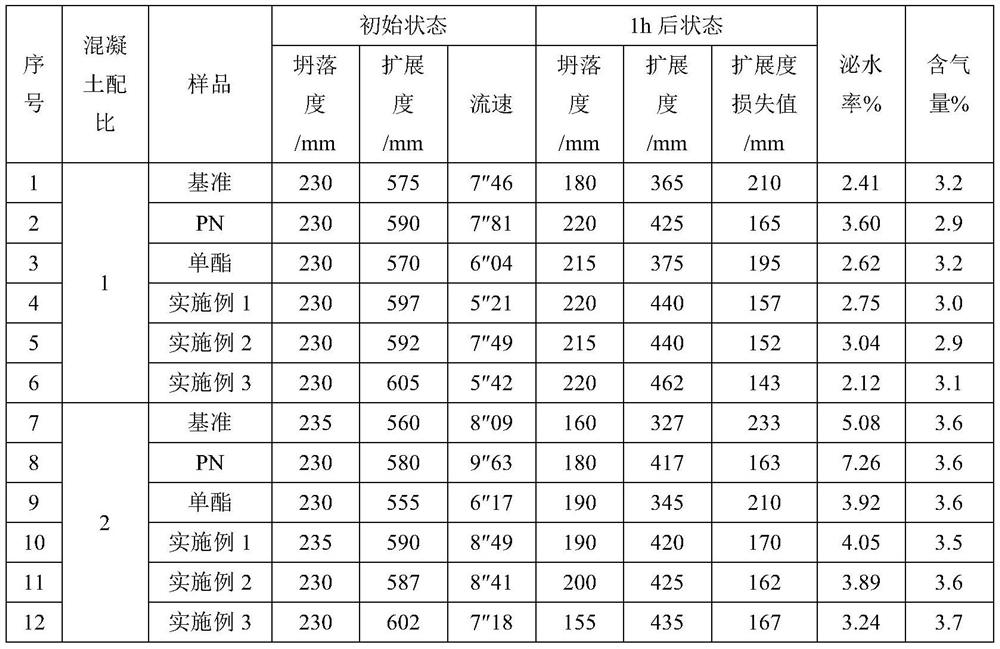

[0041] The mix ratio of concrete is shown in Table 1.

[0042] Table 1

[0043]

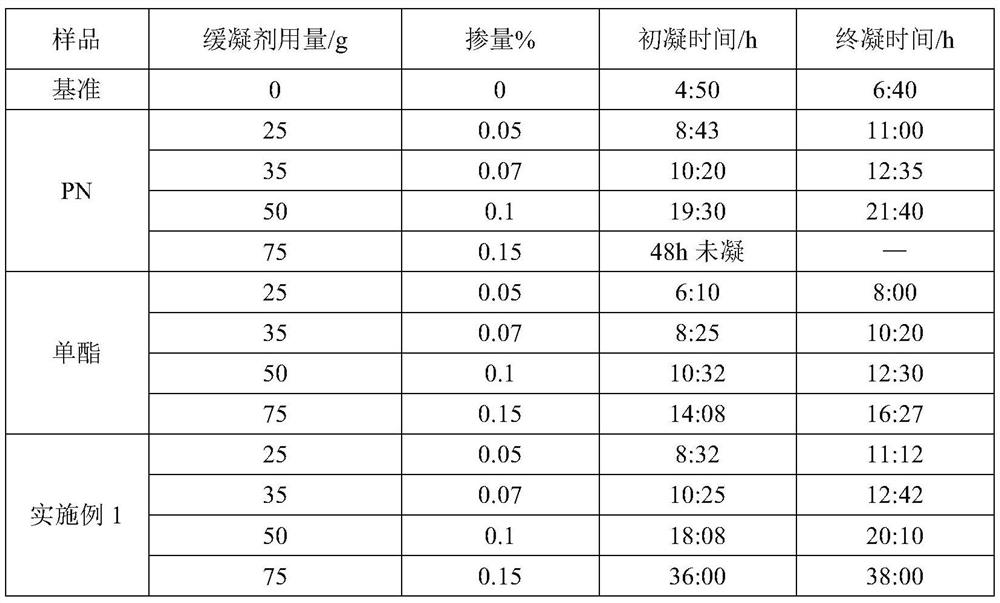

[0044] The compounding method of the modified maltose syrup sustained-release agent and the polycarboxylate water reducer as an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com