A kind of lignin anti-sludge sacrificial agent and its preparation method and application in concrete

A lignin and sacrificial agent technology, which is applied in the field of lignin anti-sludge sacrificial agent and its preparation, can solve the problems of low reactivity, poor water solubility, and environmental pollution, and achieve good water solubility, good dispersion performance, and dispersion viscosity reduction performance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Put 120g of alkaline pulping black liquor acid-analyzed alkali lignin in a beaker, add 380mL of deionized water, adjust the pH to 12 with sodium hydroxide, fully stir and dissolve for later use. A lignin reaction liquid is obtained.

[0038] (2) Add 180 g of polyethylene glycol monomethyl ether into a four-neck flask, and stir mechanically at 80° C. until dissolved. Then add 1.5g of anhydrous aluminum trichloride and continue to stir evenly. The temperature of the system was lowered to about 65°C, and at 65°C, 20mL of epichlorohydrin was added dropwise, and the reaction was continued for 3h after the dropwise addition was completed. Obtain polyethylene glycol monomethyl ether reaction intermediate.

[0039] (3) The products of step (1) and step (2) were mixed, stirred and reacted at 85° C. for 3 hours to obtain a lignin anti-sludge sacrificial agent.

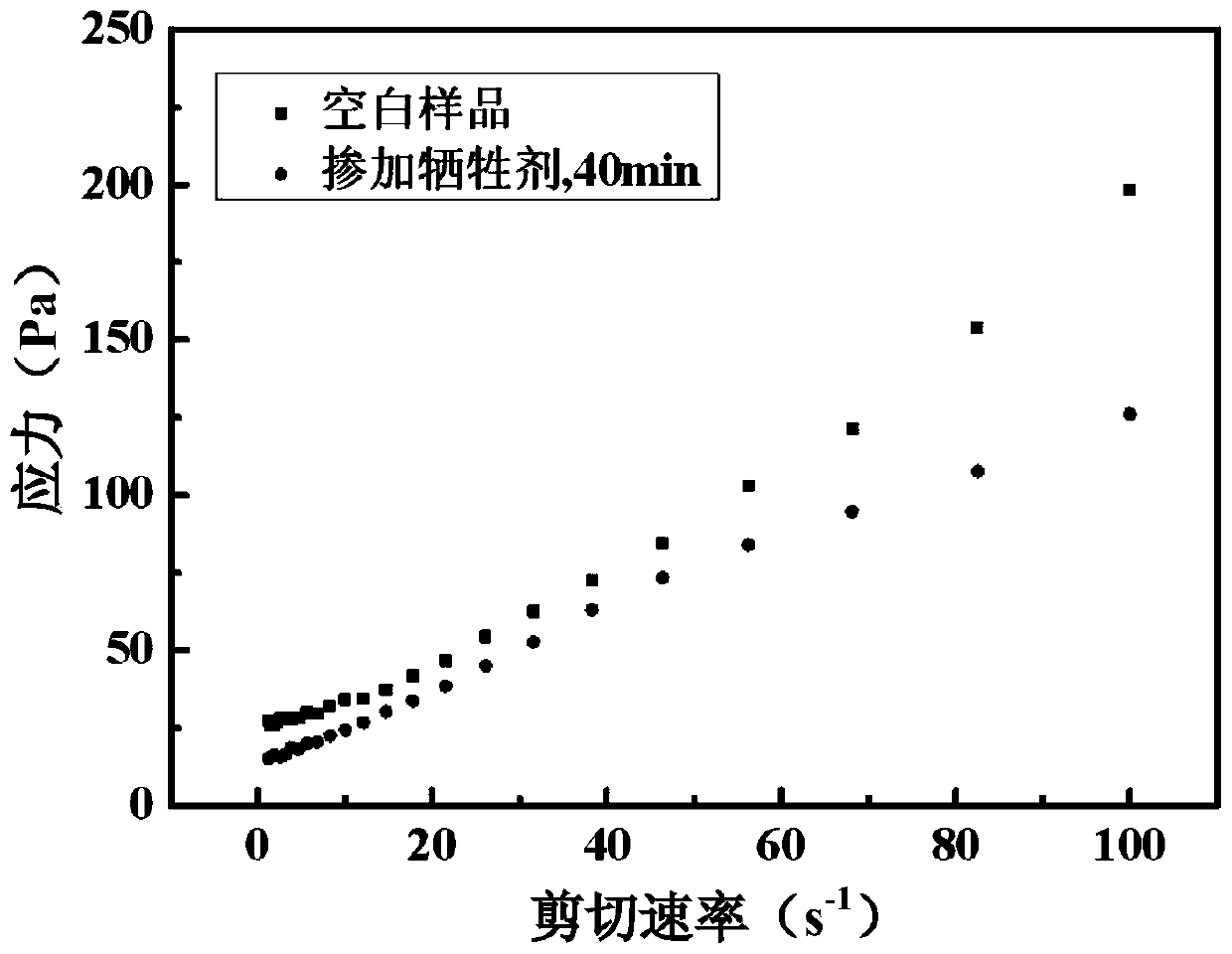

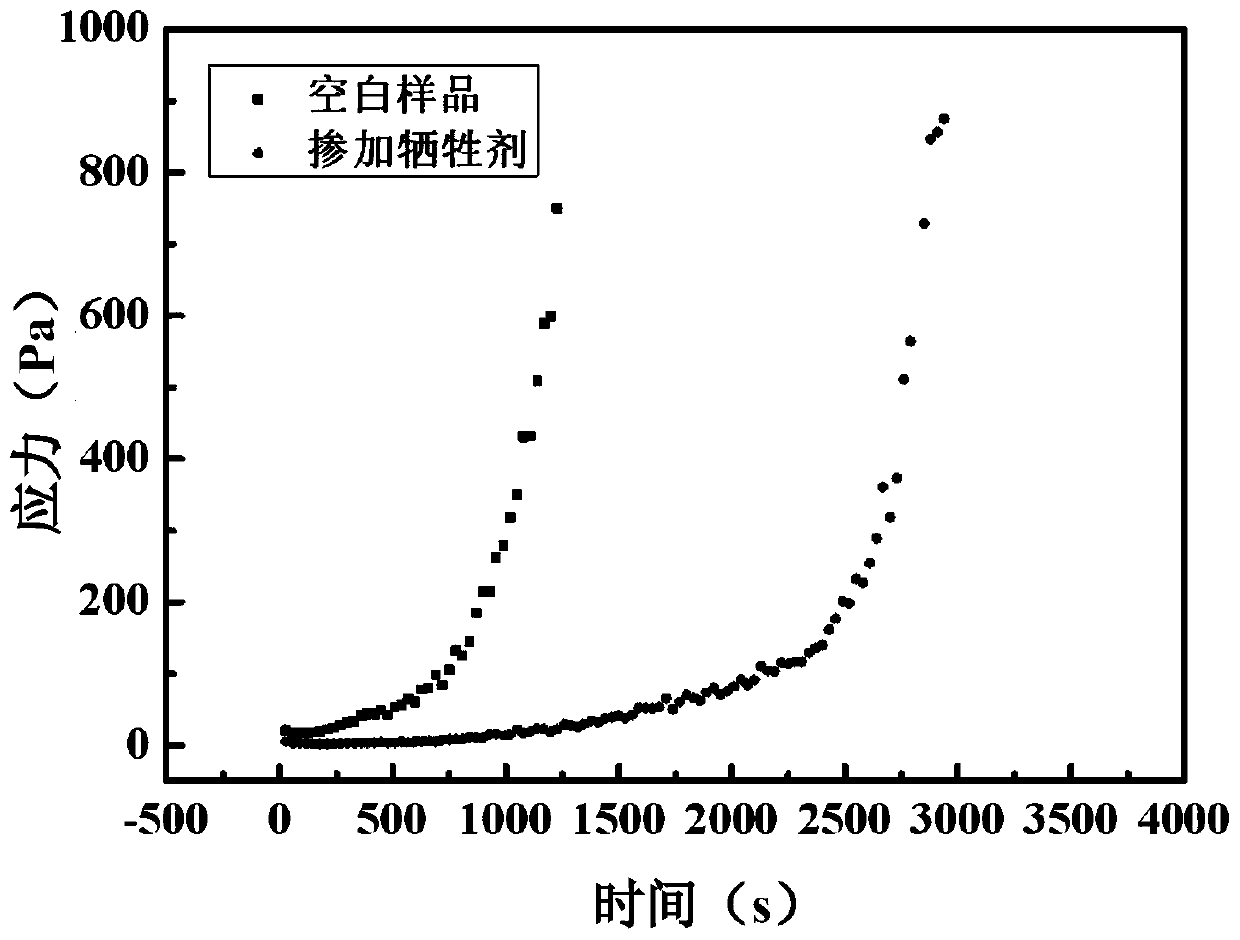

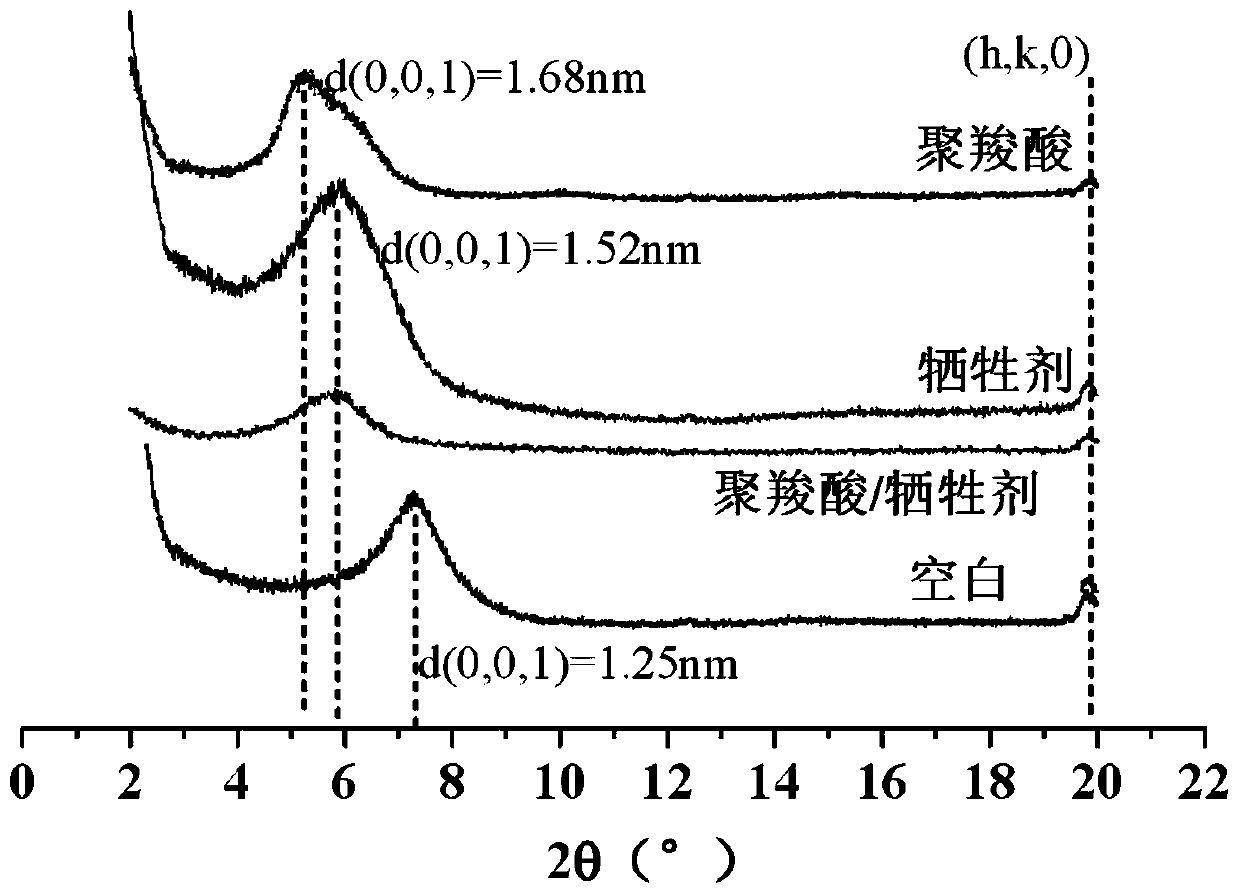

[0040]Application test of lignin anti-mud sacrificial agent of the present invention in mud-containing slurry (t...

Embodiment 2

[0052] (1) Put 120g of alkaline pulping black liquor acid-analyzed alkali lignin in a beaker, add 380mL of deionized water, adjust the pH to 12 with sodium hydroxide, fully stir and dissolve for later use. A lignin reaction liquid is obtained.

[0053] (2) Add 180 g of polyethylene oxide into a four-neck flask, and stir mechanically at 80° C. until dissolved. Then add 1.5g of anhydrous tin tetrachloride and continue stirring evenly. The temperature of the system was lowered to about 65°C, and at 65°C, 20mL of epichlorohydrin was added dropwise, and the reaction was continued for 3h after the dropwise addition was completed. A polyoxyethylene reaction intermediate is obtained.

[0054] (3) The products of step (1) and step (2) were mixed, stirred and reacted at 85° C. for 3 hours to obtain a lignin anti-sludge sacrificial agent.

[0055] Adopting the same clean pulp fluidity test as in Example 1, rheological curve test, rheological loss over time, XRD analysis and rheologica...

Embodiment 3

[0057] (1) Put 120g of bamboo pulp black liquor acid-analyzed alkali lignin into a beaker, add 380mL of deionized water, adjust the pH to 13 with sodium hydroxide, fully stir and dissolve for later use. A lignin reaction liquid is obtained.

[0058] (2) Add 180 g of methallyl alcohol polyoxyethylene ether into a four-necked flask, and stir mechanically at 80° C. until dissolved. Then add 1.0 g of boron trifluoride ether solution and continue to stir evenly. The temperature of the system was lowered to about 65°C, and at 65°C, 12mL of epichlorohydrin was added dropwise, and the reaction was continued for 3h after the dropwise addition was completed. A polyoxyethylene reaction intermediate is obtained.

[0059] (3) The products of step (1) and step (2) were mixed, stirred and reacted at 85° C. for 3 hours to obtain a lignin anti-sludge sacrificial agent.

[0060] Adopting the same clean pulp fluidity test as in Example 1, rheological curve test, rheological loss over time, XR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com