Aziridine crosslinked acrylate resin two-component water-based automobile coating and preparation method thereof

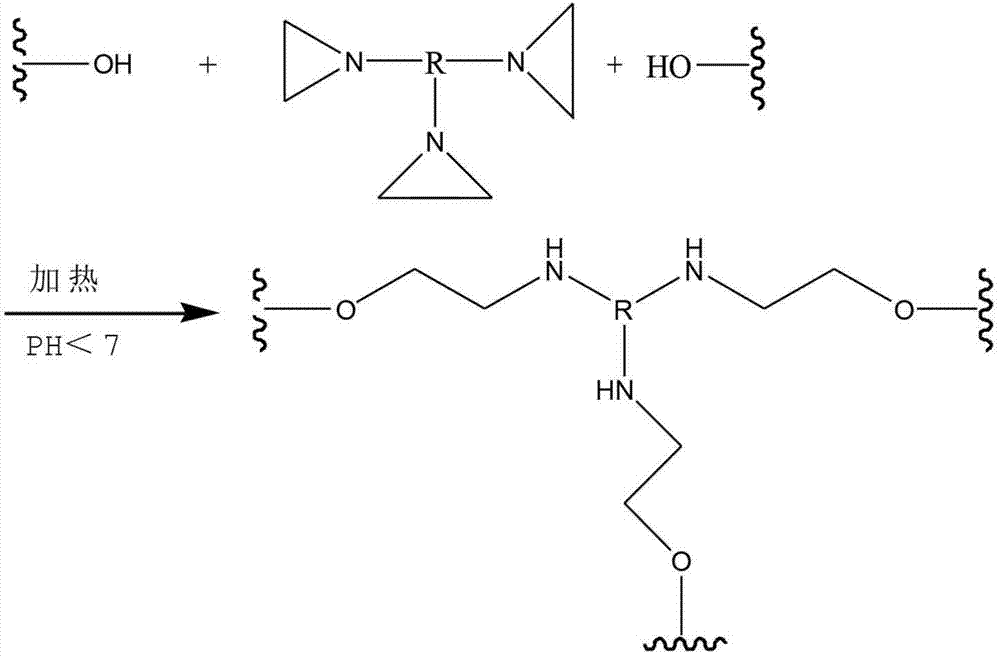

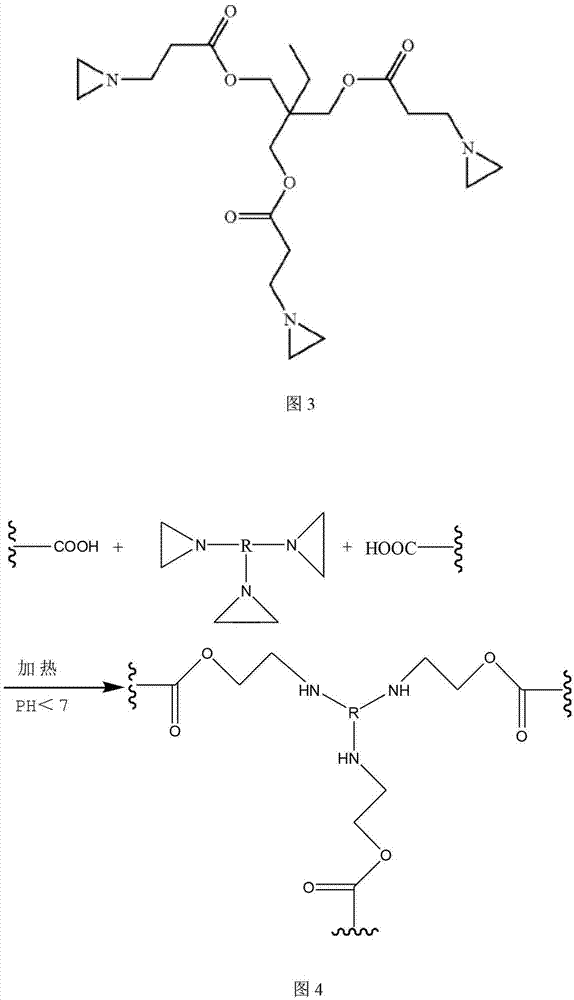

A technology of aziridine crosslinking agent and acrylate, which is applied in the field of organic polymer material preparation, and can solve the problems of large carboxyl and hydroxyl residues, poor compatibility, and poor dispersion of paint films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

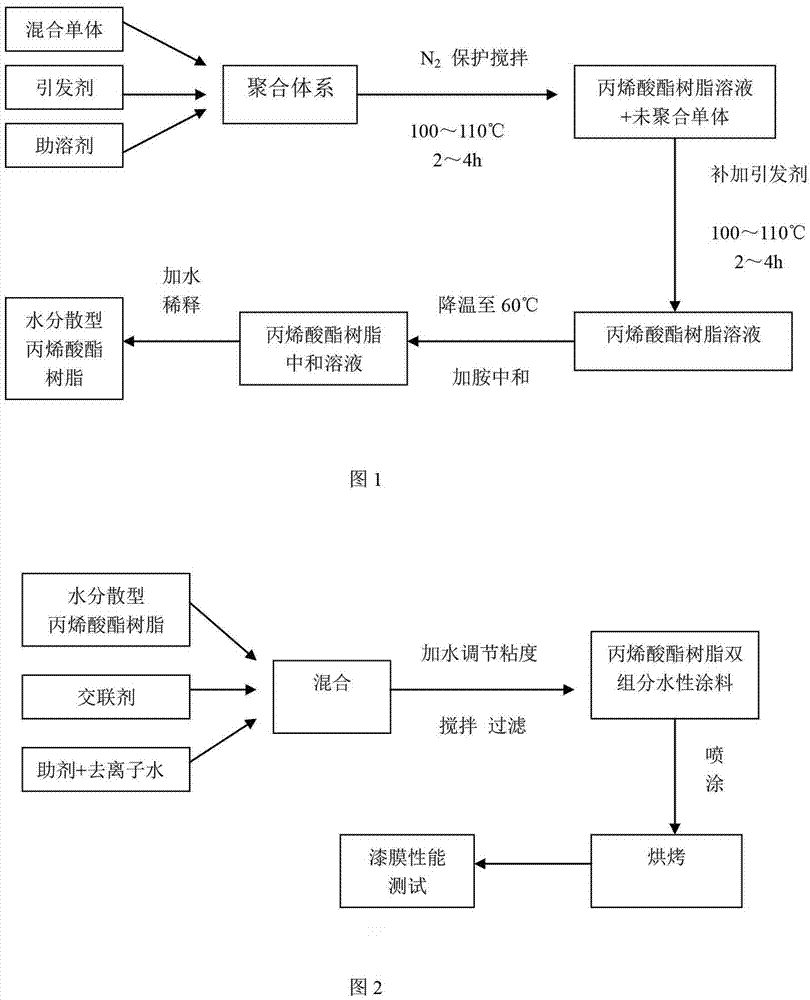

Method used

Image

Examples

Embodiment 1

[0043] Table 3 shows the combination of the functional monomer methacrylic acid and the functional monomer acetoacetoxyethyl methacrylate in Example 1. The amount of acetoacetoxyethyl methacrylate is fixed at 10%, and the methyl group is gradually increased. The dosage of acrylic acid is 7%, 8%, 9%, 10%, 11% and 14% to synthesize water-dispersible acrylate resin feeding formula, the formula number is 1, 2, 3, 4, 5 and 6. There are 6 recipes in total. The six formulations of Example 1 all use the same synthesis process as follows.

[0044] Add 25 parts of ethylene glycol diethyl ether and 15 parts of isopropanol into a four-necked flask equipped with a stirrer, condenser, thermometer and oil bath heating device. Under the protection of nitrogen, the temperature is raised to 105°C, and the amount of The mixture of acrylic acid, methyl methacrylate, styrene, acetoacetoxyethyl methacrylate, butyl acrylate, azobisisobutyronitrile and dodecyl mercaptan is dropped into the four-necked ...

Embodiment 2

[0053] Table 5 Example 2 The basic formula for synthesizing water-dispersed acrylic resin by changing the amount of acrylic acid

[0054]

[0055] Table 5 is Example 2 in the combination of functional monomer methacrylic acid and functional monomer acetoacetoxyethyl methacrylate, the amount of acetoacetoxyethyl methacrylate is fixed at 10% and the amount of acrylic acid is gradually increased It is 5.5%, 6.5%, 7.5%, 8.5%, 9.5%, and 10.5%, while correspondingly reducing the amount of methyl methacrylate. Under the condition of correspondingly reducing the amount of methyl methacrylate, the compounding formula of water-dispersible acrylate resin, the formula number is 7, There are 6 recipes in 8, 9, 10, 11 and 12. The synthesis process of each formula is the same.

[0056] According to the process of synthesizing water-dispersed acrylate resin in Example 1, the 6 water-dispersed acrylate resins numbered 7-12 as shown in Table 5 were synthesized, and the aziryl was prepared according...

Embodiment 3

[0061] Table 7 Example 3 The basic formula for synthesizing water-dispersed acrylic resin by changing the amount of acetoacetoxyethyl methacrylate

[0062]

[0063] Table 7 shows Example 3 in the combination of functional monomer methacrylic acid and functional monomer acetoacetoxyethyl methacrylate, the amount of methacrylic acid is fixed at 10% and acetoacetoxyethyl methacrylate is gradually increased. The dosage is 7%, 8%, 9%, 10%, 11%, and 14%. At the same time, the dosage of water-dispersible acrylate resin is synthesized under the condition of correspondingly reducing the amount of methyl methacrylate. The formula number is as follows There are 6 recipes in 13, 14, 15, 16, 17, and 18. The synthesis process of each formula is the same.

[0064] According to the process for synthesizing water-dispersed acrylate resin in Example 1, the 6 water-dispersed acrylate resins numbered 13-18 as shown in Table 7 were synthesized, and aziryl was prepared according to the formulation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com