Fiber composite material high-pressure hydrogen storage cylinder and preparation method thereof

A fiber composite material and composite material technology, applied in the field of fiber composite high-pressure hydrogen storage gas cylinders and its preparation, can solve the problems of poor fatigue resistance and high and low temperature impact stability, and achieve good uniformity, resin content, and defect The effect of small porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

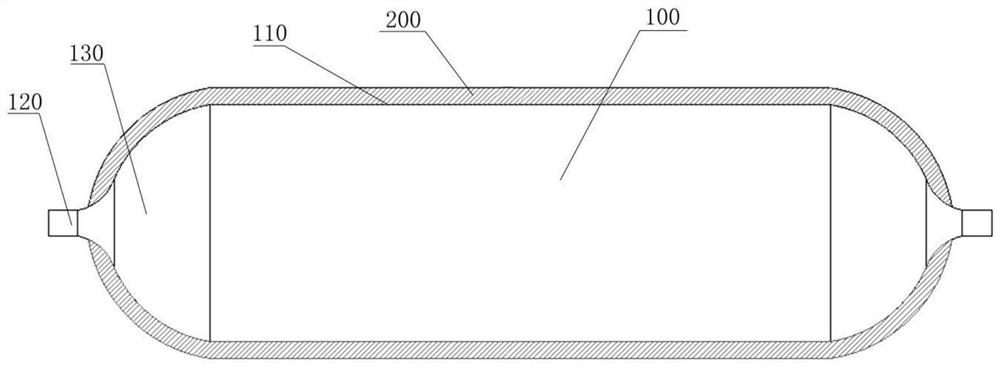

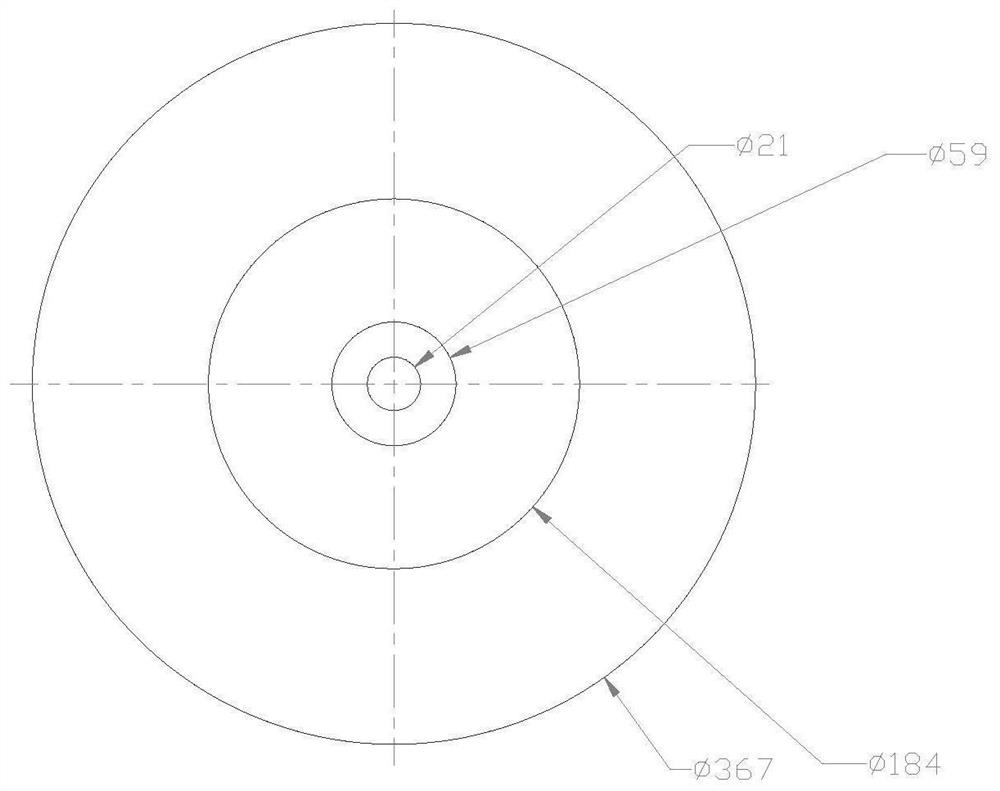

[0059] (1) Provide a cylinder liner 100 of 6061 aluminum alloy, the size of which is as follows figure 2 shown. Specifically, the maximum cross-sectional outer diameter of the liner body 110 is 367 mm, and the thickness gradually increases from 5 mm in the middle to 15 mm; the outer diameter of the bottle mouth 120 is 59 mm, and the inner diameter is 21 mm; the length of the gas cylinder liner 100 is 796 mm.

[0060] (2) The T70024K carbon fiber yarn purchased from Toray Corporation of Japan was used to carry out two-dimensional multi-spindle weaving on the outer surface of the gas cylinder liner through the Overbraiding216 spindle process to form a composite material weaving layer including multi-layer fiber two-dimensional fabric. Among them, the parameters of two-dimensional multi-spindle weaving are shown in Table 1. The weaving angle of the main part of the liner is 61-67°, the weaving angle at the bottle mouth is 15-20°, and the weaving angle at the bottle shoulder is ...

Embodiment 2

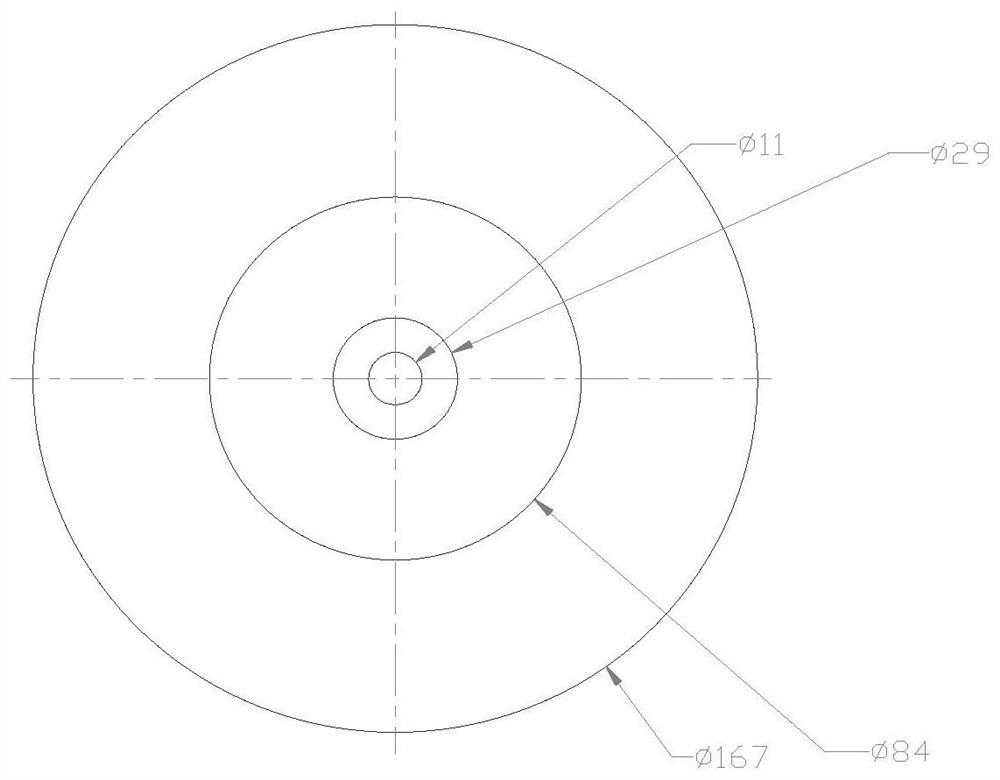

[0069] (1) Provide a cylinder liner 100 of 6062 aluminum alloy, the size of which is as follows image 3 shown. Specifically, the maximum cross-sectional outer diameter of the liner body 110 is 167 mm, and the thickness gradually increases from 4 mm in the middle to 10 mm; the outer diameter of the bottle mouth 120 is 29 mm, and the inner diameter is 11 mm; the length of the gas cylinder liner 100 is 596 mm.

[0070] (2) The T70036K carbon fiber yarn purchased from Toray Corporation of Japan was used to carry out two-dimensional multi-spindle weaving on the outer surface of the gas cylinder liner through the Overbraiding72-spindle process to form a composite braided layer including multi-layer fiber two-dimensional fabrics. Among them, the parameters of the two-dimensional multi-spindle weaving are shown in Table 1. The weaving angle of the main part of the liner is 56-62°, the weaving angle at the bottle mouth is 15-20°, and the weaving angle at the bottle shoulder is 40-50°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com