Polyimide film and method for preparing two-layer flexible copper clad laminate using the same

A technology of polyimide film and polyimide, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems such as difficult to realize double-sided flexible copper-clad laminate manufacturing, and achieve excellent dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

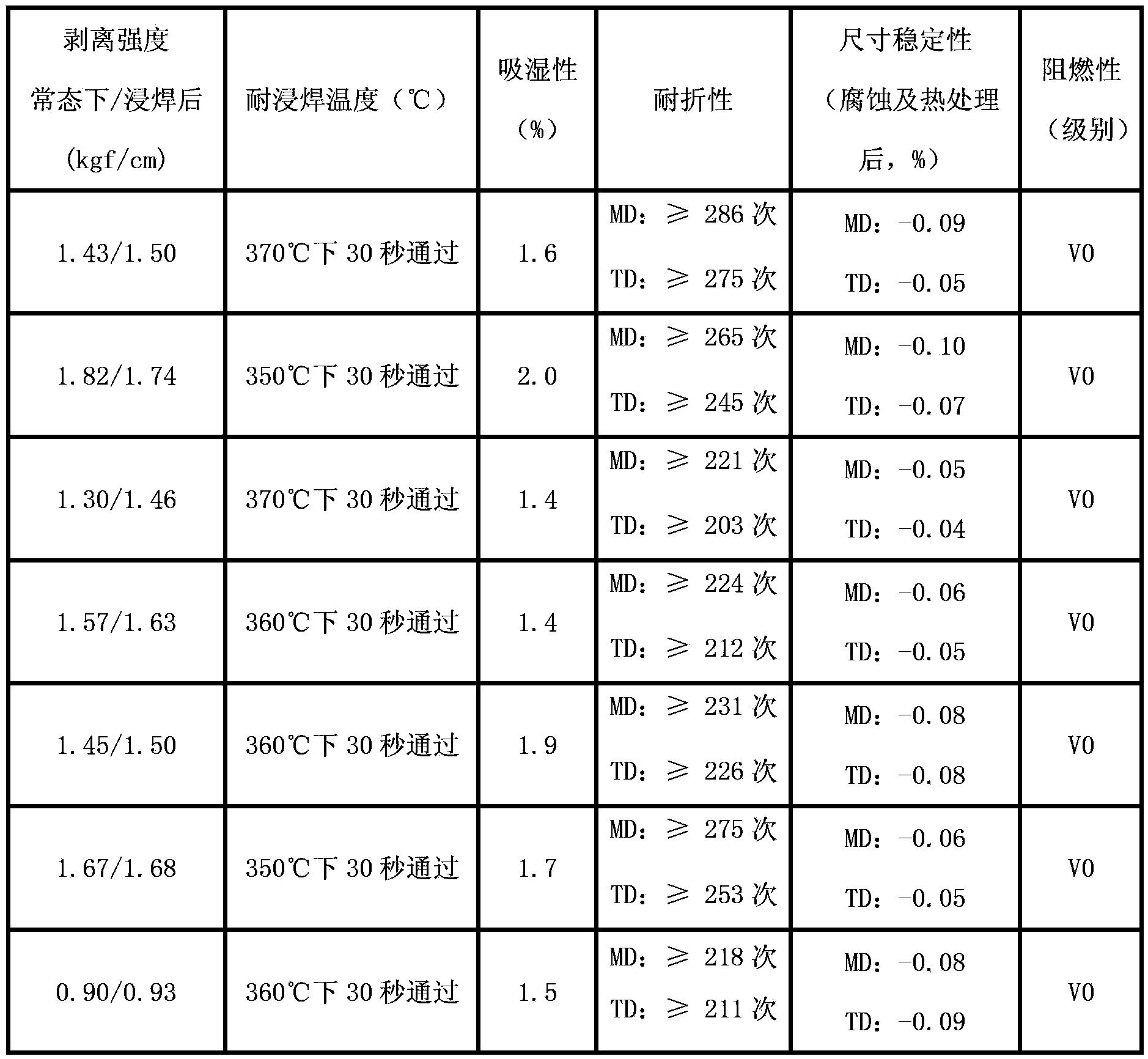

Examples

Embodiment 1

[0015]The reactor with reflux was filled with nitrogen, and 0.33mol of 3-phenyl-2,6-bis(4-aminophenyl)pyridine, 0.19mol of bis(4-aminophenyl)-4-(tribromo Methyl)phenylphosphine oxide, 0.48mol of 4,4'-methylenebis(2-tert-butylaniline), the reaction temperature was raised to 45°C, and then stirred at constant temperature for 30min to dissolve all diamine monomers in In N-methylpyrrolidone, after completely dissolving, lower the reaction temperature to 19°C, then add 0.70mol of 3,3-phenylene sulfide-4,4',5,5'- Biphenyltetracarboxylic dianhydride and 0.33 mol of pyromellitic dianhydride. After the addition of the dianhydride monomer, the reaction was carried out at a constant temperature for 6 hours to obtain a polyamic acid copolymer solution. The polyamic acid copolymer solution was adjusted to 13% with N-methylpyrrolidone, and then the solution was coated on a glass plate to control the thickness of the coating film at 0.017mm, and the coated glass plate was placed in a vacuum...

Embodiment 2

[0018] After the reactor with reflux is filled with nitrogen, add 0.47mol of 3-phenyl-2,6-bis(4-aminophenyl)pyridine, 0.19mol of bis(4-aminophenyl)-4-(tri Bromomethyl) phenylphosphine oxide, 0.21mol of 4,4'-methylenebis(2-tert-butylaniline) and 0.13mol of 4,4'-diaminodiphenyl ether, the reaction temperature was raised to 45 ℃, and then stirred at constant temperature for 30 minutes to dissolve all diamine monomers in N,N-dimethylacetamide. After complete dissolution, the reaction temperature was lowered to 20 ℃, and then 0.70mol was added in 5 times at intervals of 12 minutes. 3,3-phenylene sulfide-4,4',5,5'-biphenyltetracarboxylic dianhydride and 0.33mol of pyromellitic dianhydride. After the addition of the dianhydride monomer, the reaction was carried out at a constant temperature for 6 hours to obtain a polyamic acid copolymer solution. The solid content of this polyamic acid copolymer solution is adjusted to 10% with N,N-dimethylacetamide, then the solution is coated on ...

Embodiment 3

[0021] The reactor with reflux was filled with nitrogen, and 0.29mol of 3-phenyl-2,6-bis(4-aminophenyl)pyridine, 0.42mol of bis(4-aminophenyl)-4-(tribromo Methyl)phenylphosphine oxide, 0.29mol of 4,4'-methylenebis(2-tert-butylaniline), the reaction temperature was raised to 45°C, and then stirred at constant temperature for 30min to dissolve all diamine monomers in In N-methylpyrrolidone, after completely dissolving, lower the reaction temperature to 10°C, then add 0.23mol of 3,3-phenylenesulfide-4,4',5,5'- Biphenyltetracarboxylic dianhydride, 0.33 mol of pyromellitic dianhydride and 0.49 mol of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride. After the addition of the dianhydride monomer, the reaction was carried out at a constant temperature for 12 hours to obtain a polyamic acid copolymer solution. The solid content of this polyamic acid copolymer solution is adjusted to 13% with N-methylpyrrolidone, then the solution is coated on a glass plate, and the thickness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com