Serial double-beam high-speed laser welding method and system for galvanized double-phase steel plates and medium

A laser welding, double beam technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of reducing the mechanical properties of welding joints, reducing welding heat input, low production efficiency, etc., to prolong the cooling of the molten pool. time, the effect of reducing the hardening tendency of the weld and improving the quality of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

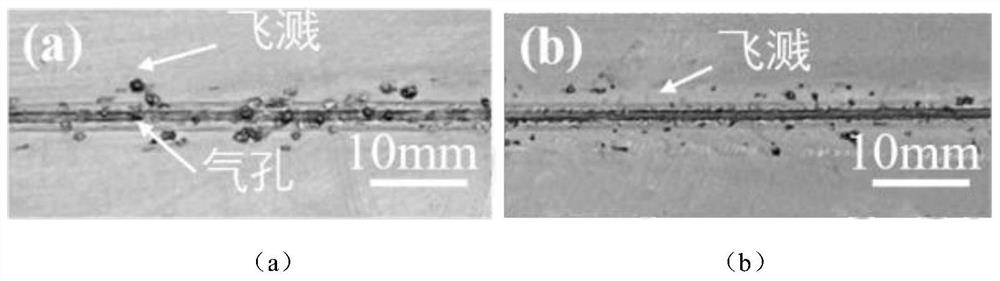

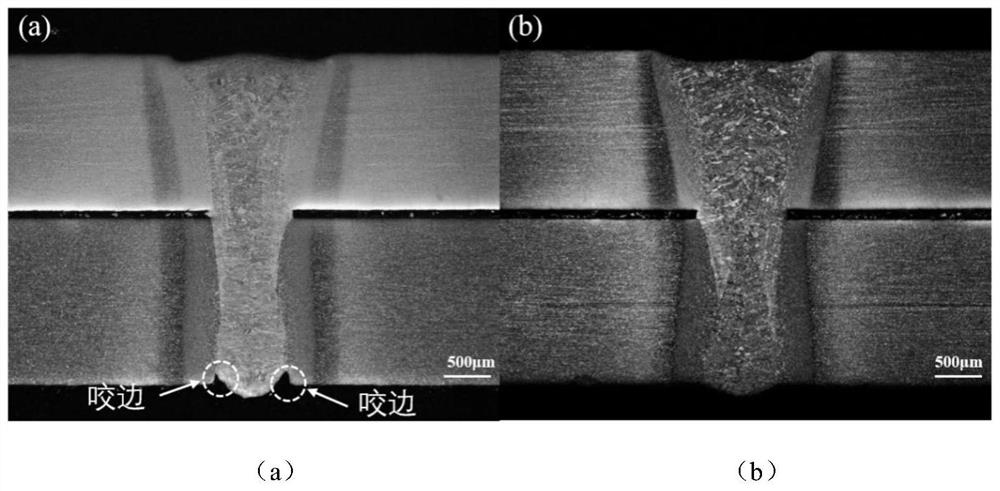

[0047] Due to the existence of the Zn coating on the galvanized steel sheet, the difference between the Zn evaporation temperature and the steel melting temperature is huge, and the Zn vapor evaporated during the welding process will have an impact on the molten pool, forming a large number of spatters, holes and other defects, which seriously affect the mechanical properties of the joint.

[0048] From the basic principle, the quality of the weld seam is largely related to the evaporation of Zn during the welding process. In order to improve the quality of the weld and increase the strength of the joint, a solution can be found in the direction of building a stable escape channel for Zn vapor.

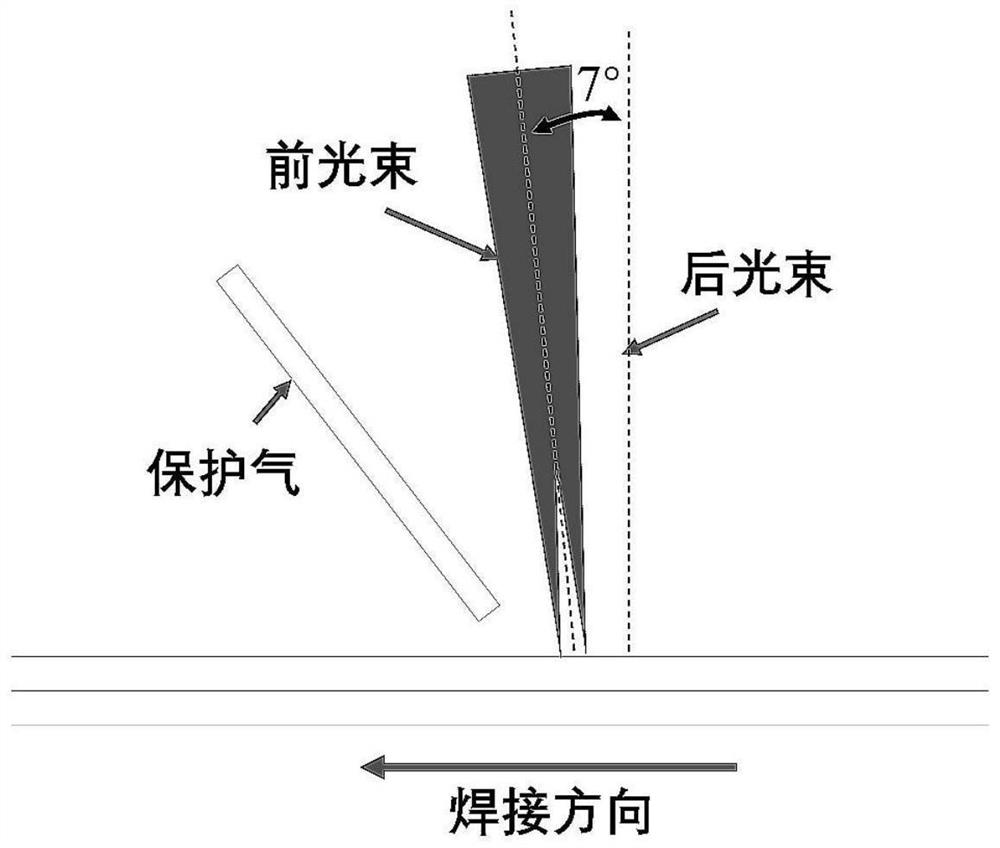

[0049] Based on the above principles, such as figure 1 As shown, the present invention provides a tandem dual-beam laser welding process to improve the forming quality and joint performance of the lap weld of galvanized dual-phase steel sheets, which specifically includes the followin...

Embodiment 2

[0067] This example provides a tandem dual-beam laser welding process to improve the lap weld formation and joint performance of galvanized dual-phase steel sheets.

[0068] In this implementation case, the experimental material is a 1.75 mm thick Zn-coated DP steel plate lapped with a 1.8 mm thick non-galvanized DP steel plate, and the Zn coating is about 10 μm.

[0069] Step 1: Take a 1.75mm DP steel plate with Zn coating and a 1.8mm thick DP steel plate without coating, purify the surface, and prepare welding fixtures for use;

[0070] Step 2: Place two DP steel plates that have undergone surface purification treatment on the workbench, where the steel plate with Zn coating is placed on the steel plate without coating, and fixed with a welding fixture to ensure that the overlapping parts of the two test plates Fits perfectly and stays flat;

[0071] Step 3: Place the double-beam laser welding head above the test plate to be welded. The incident direction of the laser beam ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com